Adjustable sensor fastening device

A fastening device and sensor technology, applied in the direction of threaded fasteners, engine sealing, connecting components, etc., can solve the problems of excessively thick sealing, inconvenience, and uncompressed compression rubber pads, and meet the operating space requirements. Small, simple locking structure, adjustable position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The adjustable sensor fastening device of the present invention will be described in detail below in conjunction with the drawings and embodiments of the specification:

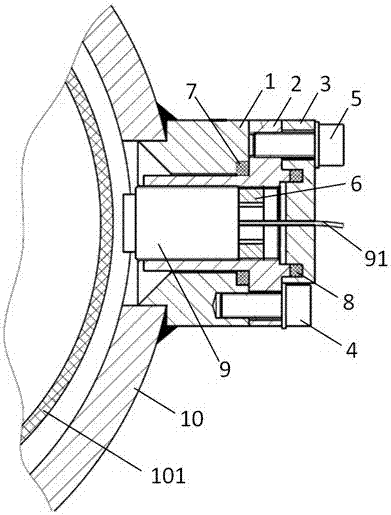

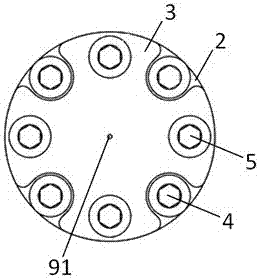

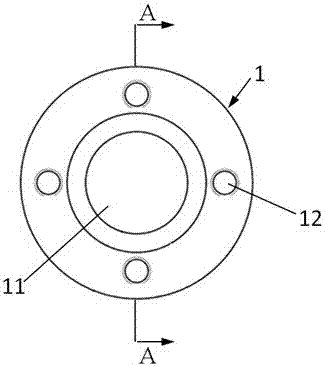

[0043] Such as figure 1 , 2 As shown, an adjustable sensor fastening device includes a base 1 fixed on the protective sleeve 10, a hollow fixing sleeve 2 fixed to the base 1 by the No. I fastening screw 4, and a No. II fastening screw 5 The sealing plate 3 fixed with the fixed sleeve 2; the No. I sealing gasket 7 is arranged between the base 1 and the fixed sleeve 2, the No. II sealing gasket 8 is arranged between the fixed sleeve 2 and the sealing plate 3, and the sensor 9 is installed on In the cavity of the fixed sleeve 2, and threadedly connected with the inner wall of the fixed sleeve 2, adjust the distance between the front end of the sensor 9 and the rotor 101 to a suitable position, lock and fix the wire end of the sensor 9 through the lock nut 6, and the lock nut 6 and the rotor 101 are locke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com