Adjustable sensor fastening device

A fastening device and sensor technology, which is applied in the direction of threaded fasteners, engine seals, connecting components, etc., can solve the problems of over-thickness, inconvenient, and non-tightening of the compression rubber pad, and meet the operating space requirements Small size, simple locking structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

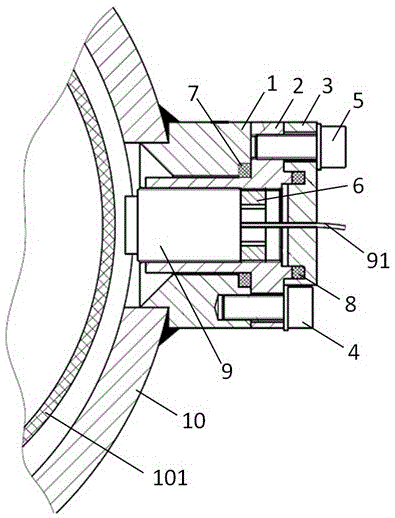

[0042] The following describes the adjustable sensor fastening device of the present invention in detail with reference to the drawings and embodiments of the specification:

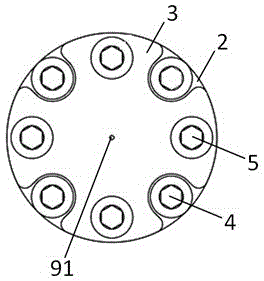

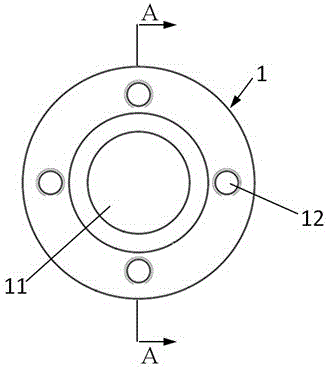

[0043] Such as figure 1 , 2 As shown, an adjustable sensor fastening device includes a base 1 fixed on a protective sleeve 10, a hollow fixing sleeve 2 fixed to the base 1 by a No. 1 tightening screw 4, and a No. 2 tightening screw 5 The sealing plate 3 is fixed to the fixing sleeve 2; the No. Ⅰ sealing gasket 7 is arranged between the base 1 and the fixing sleeve 2, and the No. Ⅱ sealing gasket 8 is arranged between the fixing sleeve 2 and the sealing plate 3. The sensor 9 is installed in In the cavity of the fixing sleeve 2 and threadedly connected to the inner wall of the fixing sleeve 2, adjust the distance between the front end of the sensor 9 and the rotor 101 to a suitable position, and lock the wire end of the sensor 9 through the lock nut 6, and the lock nut 6 is The inner wall of the fixing sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com