A direct incident optical arm magnifying 3D scanning probe

A three-dimensional scanning and probe technology, applied in the field of precision measurement, can solve the problems of high cost, low precision, and complex structure of the scanning probe, and achieve the effect of simplifying the structure, improving the measurement accuracy, and being easy to manufacture in batches.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

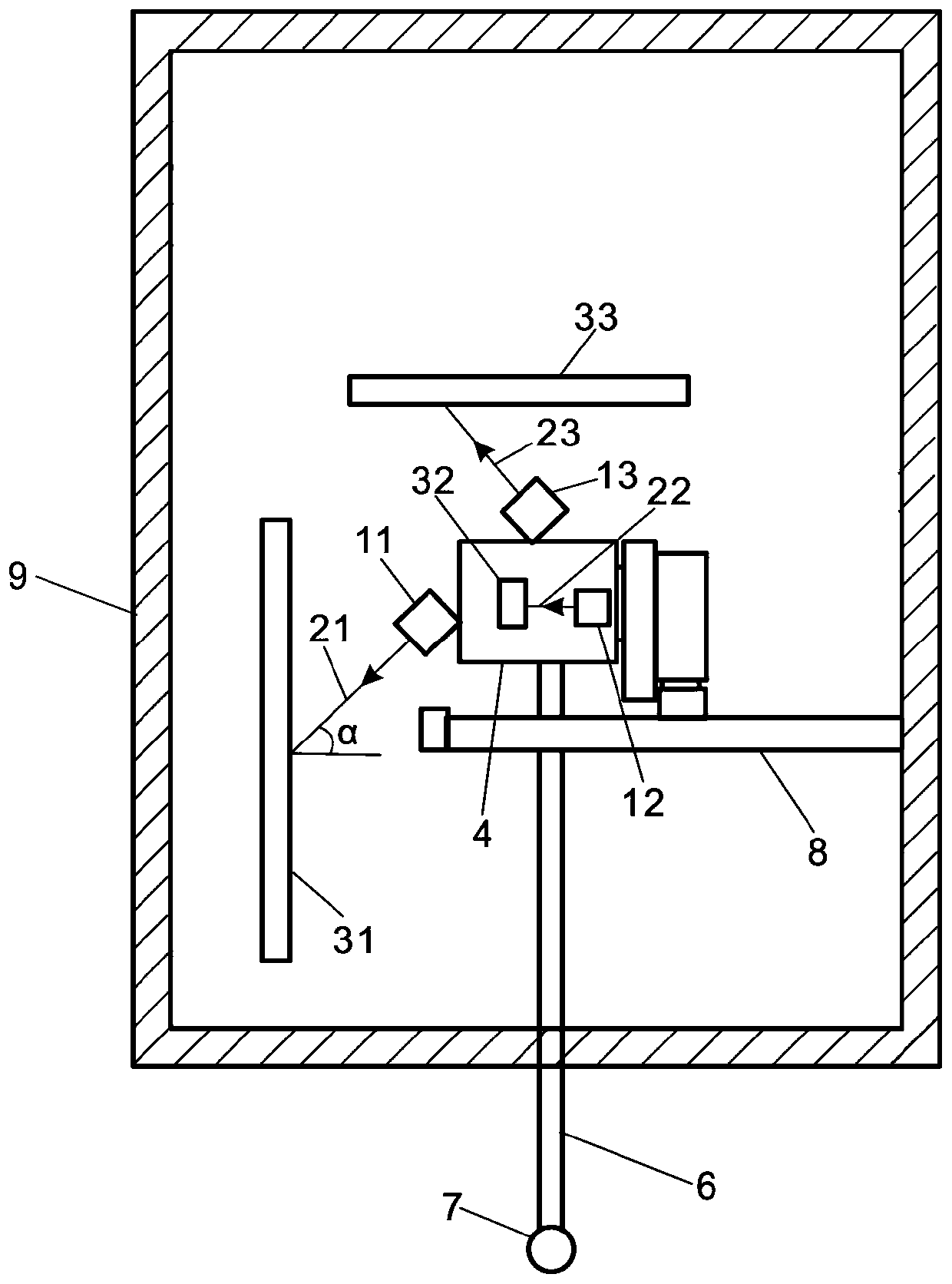

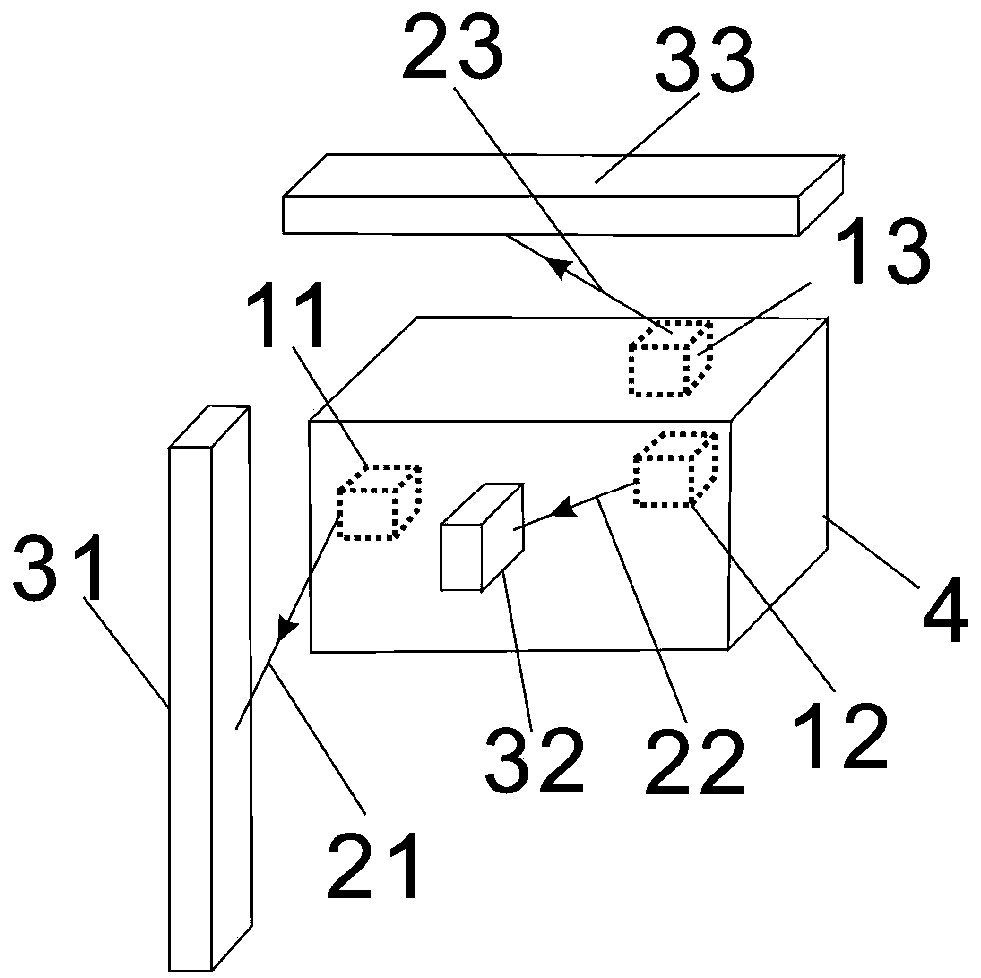

[0062] Such as figure 1 , 2 As shown, a direct-incidence optical arm magnified 3D scanning probe includes:

[0063] Three laser sources, namely laser source one 11, laser source two 12 and laser source three 13, respectively generate three laser beams, namely laser beam one 21, laser beam two 22 and laser beam three 23;

[0064] Probe base 4, said probe base 4 is provided with a laser source 11, a laser source 2 12 and a laser source 3 13, and a measuring rod 6 and a measuring ball 7 for detection;

[0065] Three photodetectors, i.e. photodetector one 31, photodetector two 32 and photodetector three 33, are respectively used to receive laser beam one 21, laser beam two 22 and laser beam three 23;

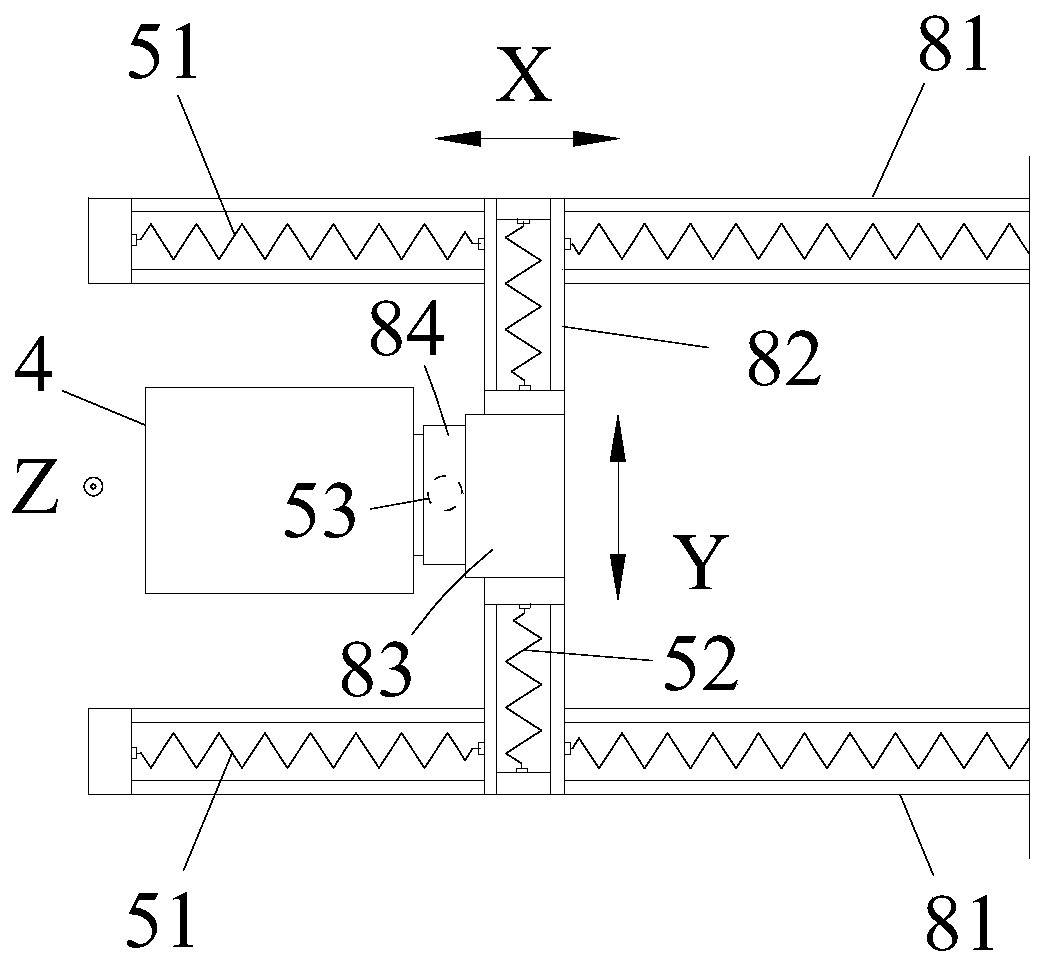

[0066] A translation component, used to make the probe base 4 move linearly;

[0067] A recovery component, used to return the probe base 4 to its initial position;

[0068] The processing system calculates and obtains the measuring ball 7 according to the incident position chan...

Embodiment 2

[0083] Such as Figure 7 As shown, a direct-incidence optical arm magnified 3D scanning probe includes:

[0084] Three laser sources, namely laser source one 11, laser source two 12 and laser source three 13, respectively generate three laser beams, namely laser beam one 21, laser beam two 22 and laser beam three 23;

[0085] Three photodetectors, i.e. photodetector one 31, photodetector two 32 and photodetector three 33, are respectively used to receive laser beam one 21, laser beam two 22 and laser beam three 23;

[0086] Probe base 4, said probe base 4 is provided with a photodetector 1 31, a photodetector 2 32 and a photodetector 3 33, and a measuring rod 6 and a measuring ball 7 for detection;

[0087] A translation component, used to make the probe base 4 move linearly;

[0088] A recovery component, used to return the probe base 4 to its initial position;

[0089] The processing system calculates and obtains the measuring ball 7 according to the incident position cha...

Embodiment 3

[0098] A direct-incidence optical arm magnified three-dimensional scanning measuring head, like Embodiment 1, includes:

[0099] Such as Figure 1-7 As shown, three laser sources, namely laser source one 11, laser source two 12 and laser source three 13, respectively generate three laser beams, namely laser beam one 21, laser beam two 22 and laser beam three 23;

[0100] Probe base 4, including measuring rod 6 and measuring ball 7 for detection;

[0101] The measuring head base 4 can be provided with three laser sources, and can also be provided with three photodetectors;

[0102] Three photodetectors, i.e. photodetector one 31, photodetector two 32 and photodetector three 33, are respectively used to receive laser beam one 21, laser beam two 22 and laser beam three 23;

[0103] The translation component and the recovery component are used to make the probe base 4 move linearly to change the incident point position of the laser beam corresponding to the photodetector;

[01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com