Non-uniform electric field robot tactile sensor and its detection method

A tactile sensor and uniform electric field technology, applied in the field of sensing, can solve problems such as non-uniformity, large measurement errors on irregular curved surfaces, and difficulty in ensuring that the electrodes meet the requirements, and achieve the effects of simple process flow, simple structure, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

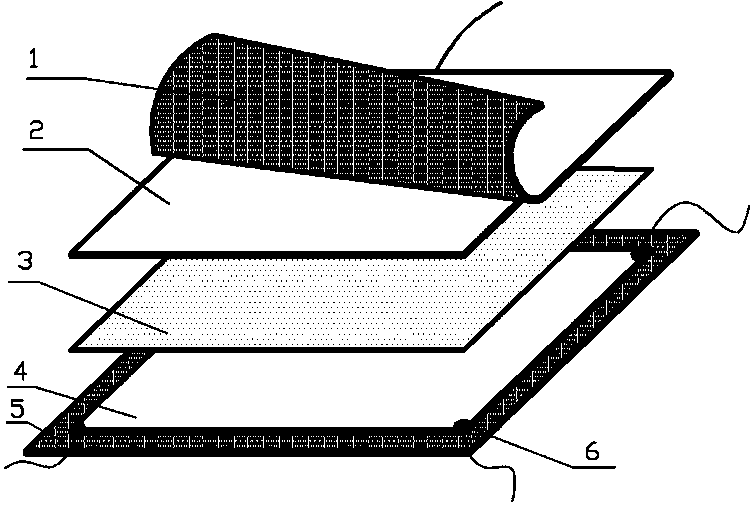

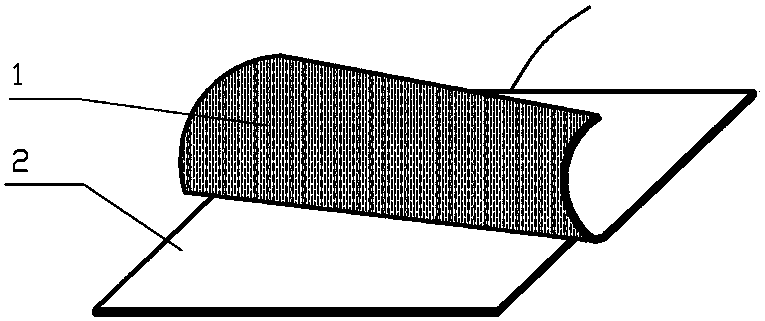

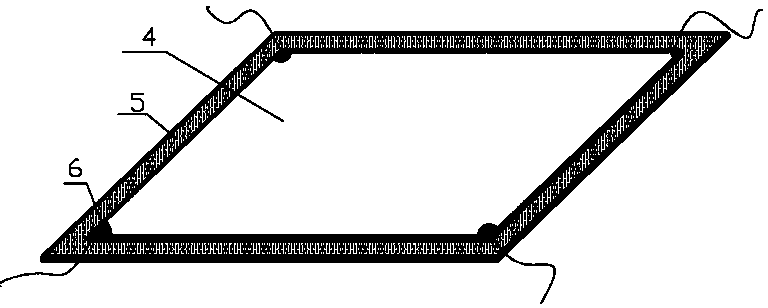

[0025] This embodiment provides a non-uniform electric field robot tactile sensor, such as Figure 1-4 As shown, it includes an upper flexible layer 11, a mesh interlayer 3 and a lower flexible layer 22. The upper flexible layer and the lower flexible layer are all composed of a conductive surface and an insulating surface, and the conductive surface is used as the upper flexible layer and the lower flexible layer. The inner surface of the lower flexible layer, the conductive surfaces 1 and 4 of the upper flexible layer and the lower flexible layer are respectively directly attached to the upper and lower sides of the mesh partition; the conductive surface of the lower flexible layer is rectangular, and the conductive surface of the lower flexible layer is rectangular. Two sets of opposite corners of the conductive surface are respectively provided with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com