Method for testing bearing capability of hydraulic energy storage workover rig

A technology of bearing capacity and testing method, which is applied in the testing of mechanical components, testing of machine/structural components, measurement of permanent deformation force through measurement gauges, etc., and can solve problems such as unsuitable hydraulic energy storage workover rigs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] 1. Turn on the metal magnetic memory detector and calibrate it, select a suitable probe according to the shape characteristics of each detection part of the hydraulic energy storage workover rig, and start scanning. When there is a large leakage magnetic field gradient, mark it with a marker pen.

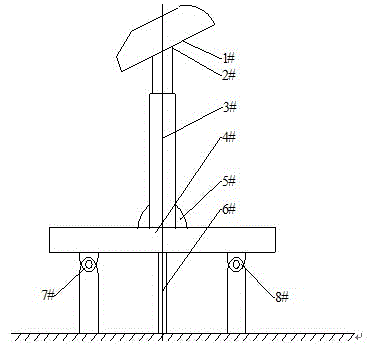

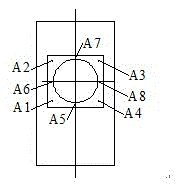

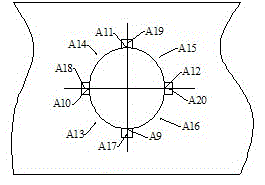

[0060] 2. Through a comprehensive scan of the hydraulic energy storage workover rig's main stress-bearing components, damaged or corroded components, sudden changes in the cross-section of the derrick, key component connections, key welds and other parts of the hydraulic energy storage workover rig, it was found that There are 3 stress concentration areas, all of which are located on the 3 fixed ear plates at the lower end of the main oil cylinder. According to the metal magnetic memory test results and the force characteristics of the derrick, a total of 32 measuring points were arranged in this test. The middle section of the column (3# module), the rotating platform (4# m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com