Detecting method for railawy freight car loading weight

A railway freight car, bearing weight technology, applied in the field of freight car load detection, can solve the problems that affect the efficiency of railway freight, easy subjective judgment, high labor intensity, etc., and achieve the effect of convenient carrying capacity and easy popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

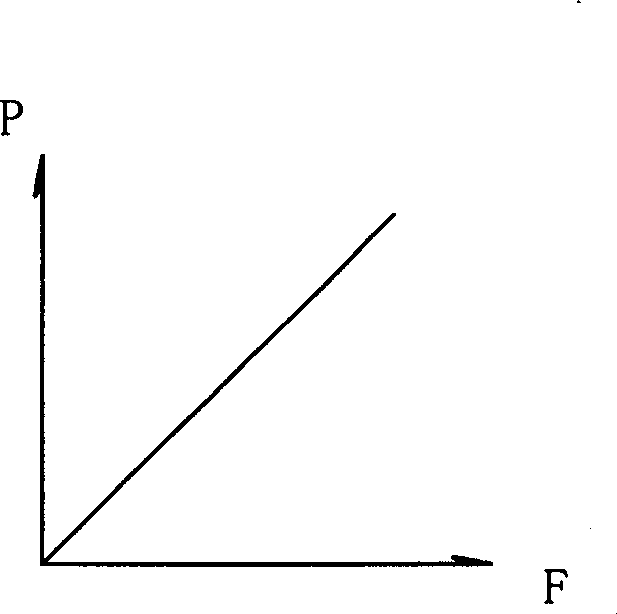

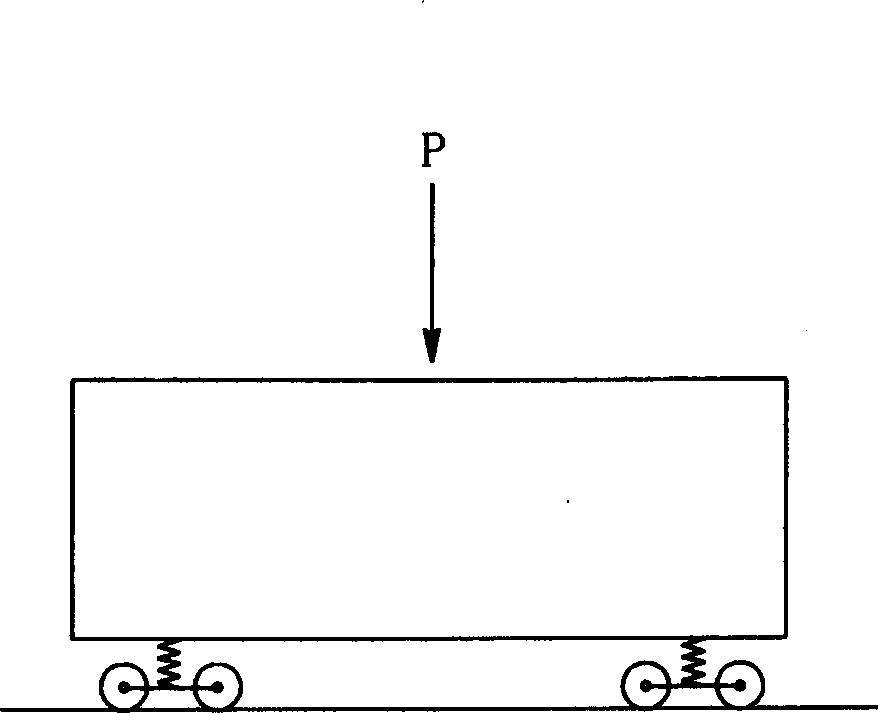

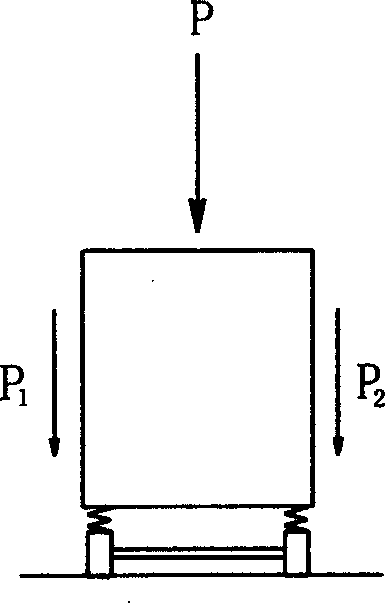

[0024] The method for detecting the carrying weight of railway freight cars is to use a portable railway freight car overweight and partial load detector to detect the deflection f of the four groups of spring groups of the two bogies respectively 1 , f 2 , f 3 , f 4 . The bogie is type 8A. Spring stiffness K=540 / mm.

[0025] Measured: f 1 =16.11mm

[0026] f 2 =20.82mm

[0027] f 3 =15.98mm

[0028] f 4 =20.28mm

[0029] Then there is: P 1 = f 1 ·K=8.70 tons

[0030] P 2 = f 2 ·K=11.24 tons

[0031] P 3 = f 3 ·K=8.63 tons

[0032] P 4 = f 4 ·K=10.95 tons

[0033] P=P 1 +P 2 +P 3 +P 4 = 8.70 tons + 11.24 tons + 8.63 tons + 10.95 tons = 39.52 tons

[0034] That is, the load capacity of railway wagons is 39.52 tons.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com