Gas-liquid two phase thermal-engineering experiment heat loss calibration method and calibration device

A thermal experiment and calibration device technology, applied in the direction of material thermal development, etc., can solve the problems of underestimating heat loss, overestimating heat loss, inaccuracy, etc., to improve accuracy and reliability, and the evaluation value is reliable and More simple and convenient, simple and accurate calibration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

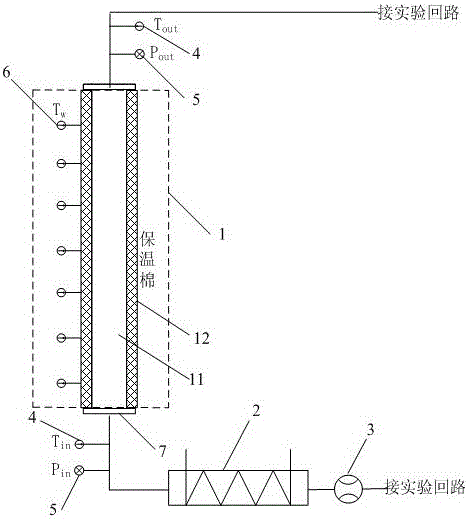

[0035] In the thermal experiment, the two ends of the experimental section 1 are generally connected in the experimental loop through pipelines, and the calibration device of the present invention calibrates the heat loss of the experimental section 1 .

[0036] like figure 1 As shown, the calibration device for the heat loss of the vapor-liquid two-phase thermal experiment includes the experimental section 1 connected in the experimental circuit, the preheater 2 for heating the fluid, the wall temperature measuring device 6 for measuring the outer wall of the experimental section 1, The flowmeter 3 that measures the flow rate of the fluid passing through the experimental section 1; the flowmeter 3, the preheater 2, and the experimental section 1 are connected in series in sequence, and the preheater 2 is connected to the inlet of the experimental section 1, the outlet of the experimental section 1 and the The flowmeters 3 are all connected to the experimental loop, and the fl...

Embodiment 2

[0048] The calibration method for the heat loss of the vapor-liquid two-phase thermal experiment also includes the steps of determining the amount of heat loss in the two-phase thermal experiment, specifically including the following steps:

[0049] S41. In the two-phase thermal experiment, measure the temperature of the outer wall of the experimental section 1; the aforementioned two-phase thermal experiment refers to a formal thermal experiment conducted by introducing a vapor-liquid two-phase fluid;

[0050] S42, Substituting the outer wall temperature of the experimental section 1 measured in step S41 into the functional relationship between the wall temperature Tw obtained in step S3 and the heat loss Qloss to calculate the heat loss, or according to the experimental section 1 measured in step S41 Find the corresponding amount of heat loss from the relationship diagram obtained in step S3 for the temperature of the outer wall. If only the functional relational expression ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com