Preparation method and application of butter enzymolysis base material

A cream and enzymatic hydrolysis technology, applied in the field of preparation of cream enzymatic hydrolysis base material, can solve problems such as hidden dangers in emulsion stability, influence on effect, and limited application range, so as to improve the utilization rate of cream, real milk flavor components, and improve Food Flavor and Mouthfeel Effects

Active Publication Date: 2017-09-12

HANGZHOU EVER MAPLE FLAVOR & FRAGRANCE

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the milk-flavored base material prepared by this method is oil-soluble, and its application range is limited. To make it water-soluble, it needs to be obtained after emulsification of the cream enzymolysis base material. The process is relatively complicated, and there are hidden dangers in the stability of the emulsion. In the process, the butter enzymolysis base material as the oil phase only accounts for 5%-20% of the entire emulsification system, and the aroma and fragrance are diluted, affecting the effect

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

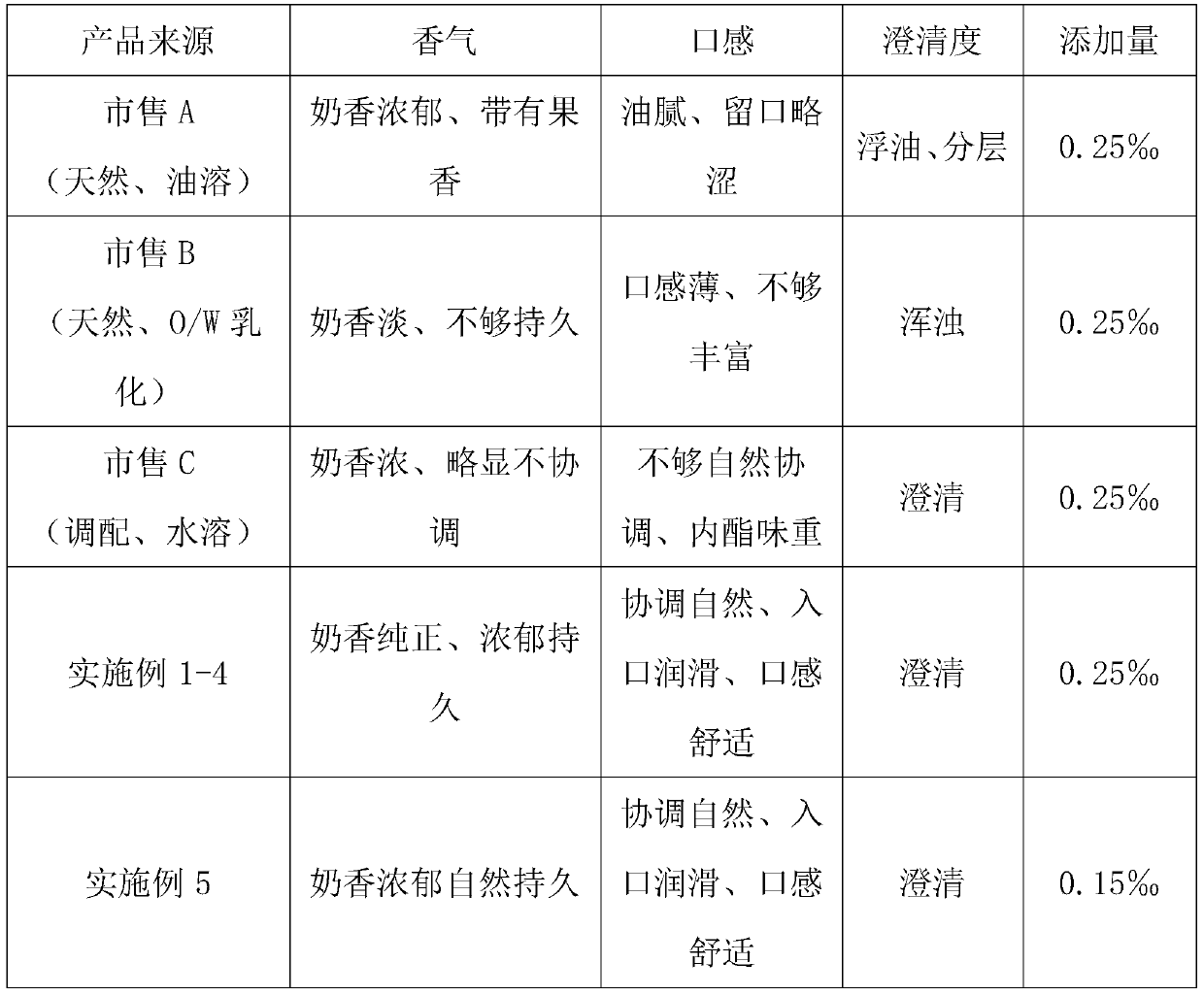

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

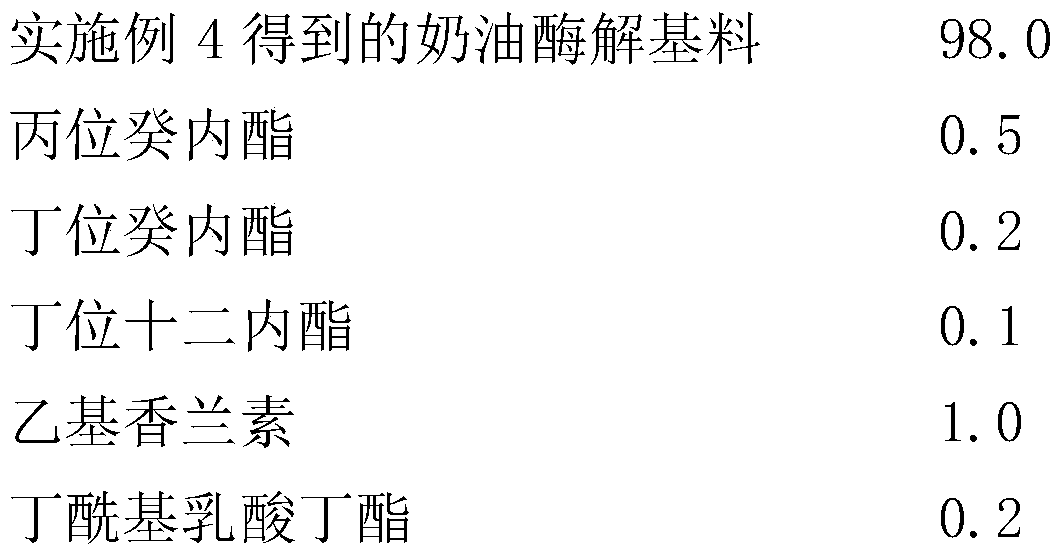

The present invention discloses a cream flavored enzymolyzed base material preparation method and an application thereof. The preparation method comprises the following steps excess natural mixed solvent is added into anhydrous cream, microorganism derived lipase is added into the anhydrous cream to conduct catalyzed transesterification, the mixture is subjected to centrifugation, an upper layer is taken, partial sterile water is added into the upper layer, and animal pancreas derived lipase is used to conduct catalyzed hydrolysis to release fatty acids, and the hydrolyzed mixture is concentrated thereby to obtain water-soluble cream flavored enzymolyzed base material. The obtained cream flavored enzymolyzed base material can be directly used as food ingredients to be added into food, improve food flavor and texture, and can also be used as a raw material to be blended to obtain a cream essence for application. Besides, the obtained cream essence has a natural sense of coordination, no adverse chemical gas, and has significant progress compared with the existing products in the market. The preparation technology is simple, is low in cost, and has broad market prospects.

Description

Preparation method and application of butter enzymatic hydrolysis base material Technical field The invention relates to a preparation method and application of a food additive, in particular to a preparation method and application of a butter enzymatic hydrolysis base material. Background technique In the process of food industrialization, food additives have played a pivotal role. With the improvement of living standards, consumers are increasingly demanding natural food health. Therefore, how to use natural raw materials to develop natural food additives has become the research focus of enterprises and colleges. Dairy products are an important part of food. There are many types of food additives developed around dairy products, and the market is also wide. Lipase is a type of enzyme preparation that can hydrolyze triglycerides and release fatty acids. At this stage, universities and enterprises use lipase to enzymatically hydrolyze anhydrous butter to release medium and sh...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): A23L27/20A23L29/00

CPCA23C13/16A23V2002/00A23V2250/082A23V2250/086A23V2250/76

Inventor 陈雄王昕悦郭宁黄伟沈国陈荣荣楼盈凯

Owner HANGZHOU EVER MAPLE FLAVOR & FRAGRANCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com