Hot melt adhesive coating machine and gluing system

A gluing machine and hot-melt adhesive technology, applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of glue decomposition, scalding the operator, and difficulty in applying and scraping the glue, so as to achieve easy production and stickiness. The effect of high bonding strength and dense bonding surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

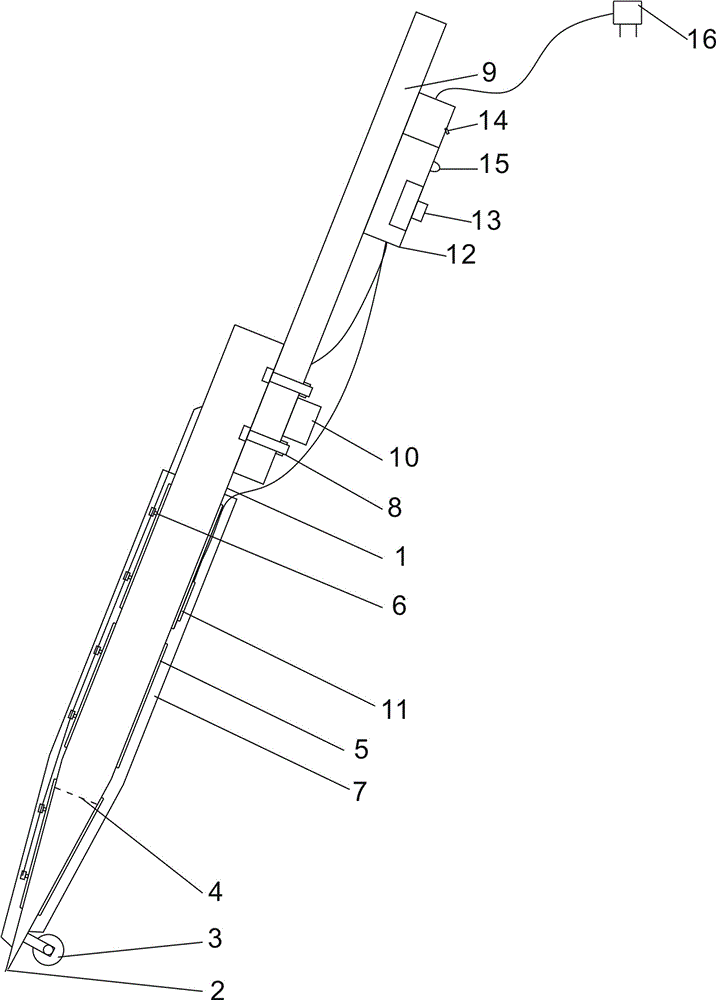

[0024] Such as figure 1 As shown, the hot melt glue applicator: includes a metal tube 1 (a thin-walled tube with a wall thickness of 3mm or less), and the bottom of the metal tube 1 is in the shape of a flat mouth (the opening of the flat mouth does not exceed 3mm, and the width depends on the width of the glue) As the nozzle 2, a bearing 3 is fixed on the metal pipe 1 below the nozzle 2, and a filter screen 4 is installed in the lower cavity of the metal pipe 1 (welded by a metal strip passing through the wall of the metal pipe 1) ), the outer circumference of the metal tube 1 is provided with three sections of heating ring 5 from top to bottom (processed and formed for the high temperature resistant insulating mica heater wrapped in metal skin), each section of heating ring 5 is provided with two terminals 6, and the outer circumference of heating ring 5 An insulation cover 7 is provided, and the insulation cover 7 is composed of (high temperature resistant) glass wool, glas...

Embodiment 2

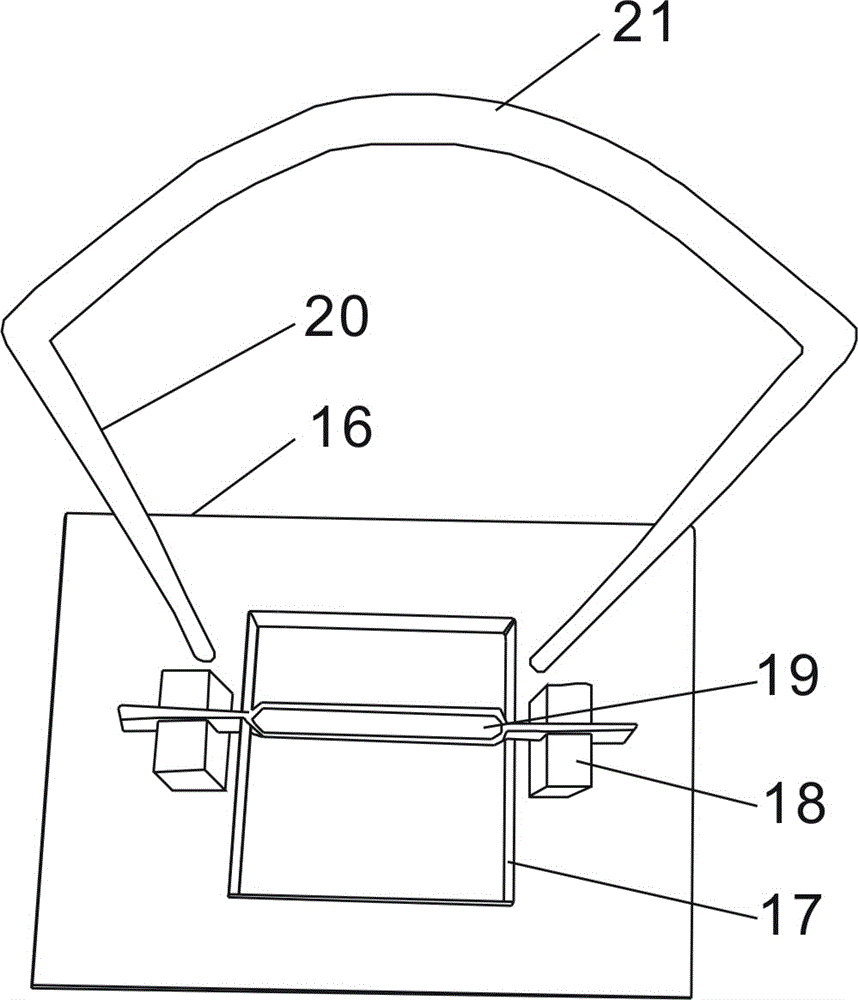

[0027] Hot-melt glue application system, including glue application machine and supporting machine base.

[0028] The structure of gluing machine is the same as embodiment 1, and the structure of support is as figure 2 Shown: including wooden pallet 16, glue box 17, support frame, two wooden buttresses 18, accommodating tank 19 (made of iron sheet, the shape of the inner tank is a flat mouth matching with the glue nozzle 2), wooden Two smooth metal round sticks ( figure 2 not shown), the support frame is made up of two vertical round bars 20 and an arc-shaped round bar 21, and the two vertical round bars 20 are fixed on the wooden pallet 16 at intervals, and the two ends of the arc-shaped round bars 21 are They are respectively fixedly connected to the tops of the two vertical round steels 20, and the two wooden buttresses 18 are fixed on the wooden pallets 16 in front of the two vertical round steels 20 at intervals, and the glue box 17 is arranged on the two wooden buttre...

Embodiment 3

[0031] Hot-melt glue application system, including glue application machine and supporting machine base.

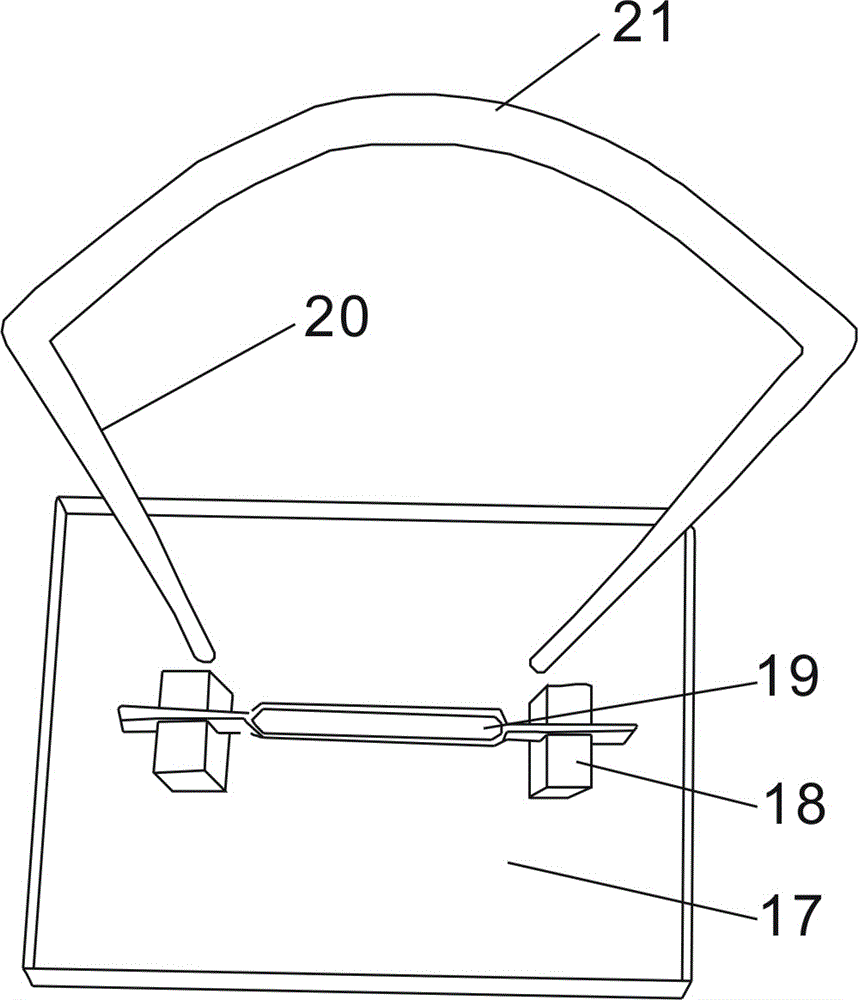

[0032] The structure of gluing machine is the same as embodiment 1, and the structure of support is as image 3 As shown: the machine base includes a glue box 17, a support frame, two wooden buttresses 18, and an accommodating groove 19. The support frame is composed of two vertical round steels 20 and an arc-shaped round steel 21. Two vertical The round steel 20 intervals are fixed in the glue box 17, the two ends of the arc-shaped round steel 21 are fixedly connected with the tops of the two vertical round steels 20 respectively, and the two wooden buttresses 18 are fixed at intervals in front of the support frame. In the glue box 17 , the shape of the receiving groove 19 is adapted to the shape of the glue nozzle, and the two ends of the receiving groove 19 extend to two wooden buttresses 18 and are erected on the two wooden buttresses 18 .

[0033] The application pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com