A kind of folding fan bamboo bone primary selection and intensive repair equipment

A technology of equipment and bamboo bones, applied in the field of primary selection and finishing equipment for folding fan bamboo bones, can solve the problems of large labor, low efficiency, poor product quality stability, etc., achieve a high degree of mechanical automation, avoid waste of resources, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

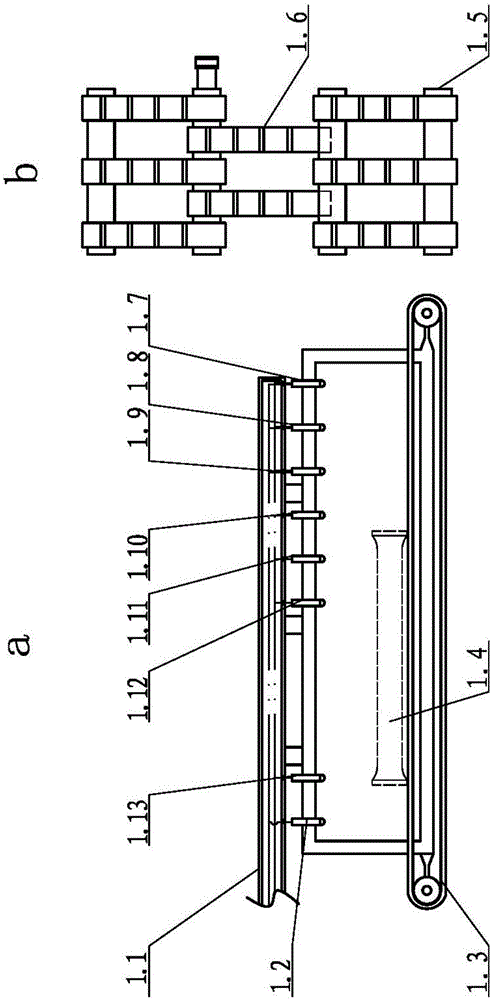

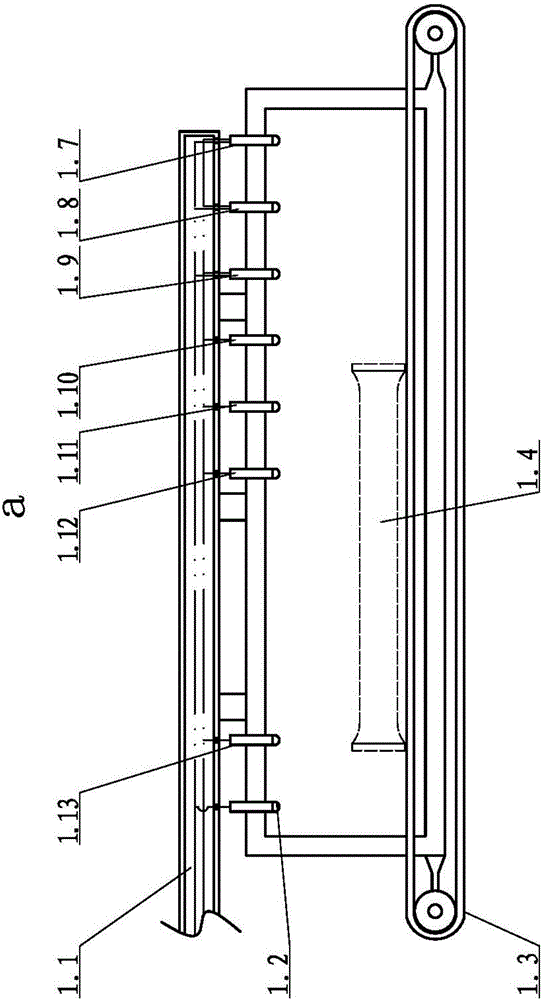

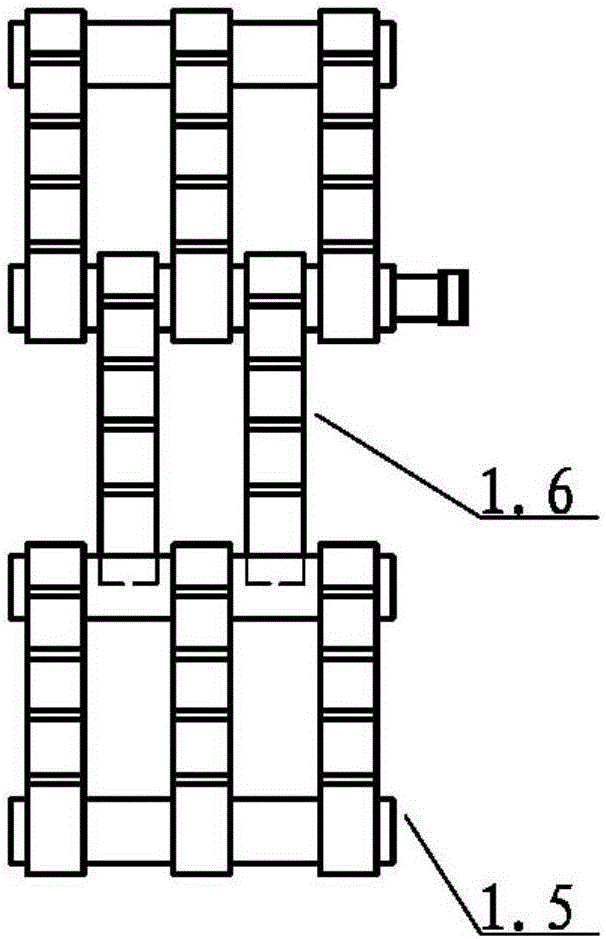

[0058] Such as figure 1 and 2 As shown, a kind of primary selection and finishing equipment for bamboo bones of folding fan, including primary selection equipment for bamboo material length, primary selection equipment for bamboo material curvature and fixed-length finishing equipment for bamboo material; primary selection equipment for bamboo material length and primary selection equipment for bamboo material curvature They are connected by a stepped selection conveying device.

[0059] Wherein, the bamboo material length preliminary selection equipment comprises a frame, a conveyor belt is set below the frame, and a length sensing probe is set on the frame, and the length sensing probe includes more than one front-end probe and more than two rear-end probes; A length primary selection controller is included, and the length primary selection controller is connected with the front-end probe and the rear-end probe. The length sensing probe includes two front-end probes and si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com