Servo motor mold opening and closing mechanism for rotary bottle blowing machine

A servo motor and bottle blowing machine technology, applied in the field of bottle blowing machines, can solve problems such as wear of rollers and cam guide rails, inability to further increase the speed, and affect the mechanical stability of the blow molding machine, and achieve the effect of solving the speed bottleneck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

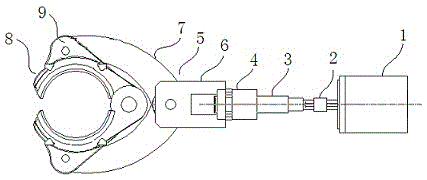

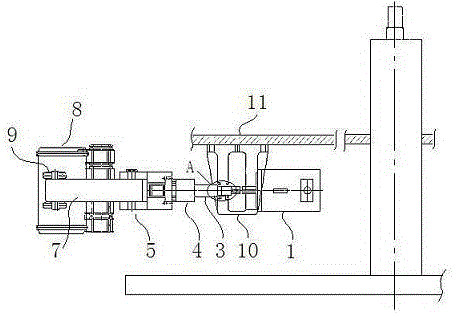

[0018] attached figure 1 , 2 As a specific embodiment of the present invention, this embodiment adopts the hanging ear type formwork 8, which includes a connecting assembly 5 connected to the hanging ear type formwork, and the connecting assembly is connected by a screw screw sleeve transmission mechanism. Servo Motor 1.

[0019] Further, the connecting assembly includes two connecting frames 7 and connecting seats 6, the ends of the two connecting frames are hinged on the connecting seats, and the front ends are respectively hinged on the hanging ears 9 of the ear-hanging formwork;

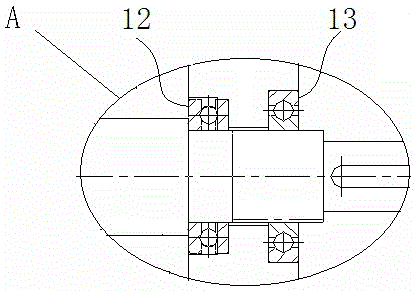

[0020] Further, the connection seat of the connecting assembly is fixedly connected to the screw sleeve 4 in the screw sleeve transmission mechanism, and the output end of the servo motor is fixed to the lead screw 3 in the screw sleeve transmission mechanism through a coupling 2 connect. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com