Elevator door vane

A door knife and elevator technology, which is applied in the mechanical field, can solve the problems that the switch trigger and the lock hook have a large difference in rotation radius, and the switch trigger cannot be disconnected from the lock hook to unlock at the same time, so as to improve fluency and safety. Guarantee the effect of normal opening and closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

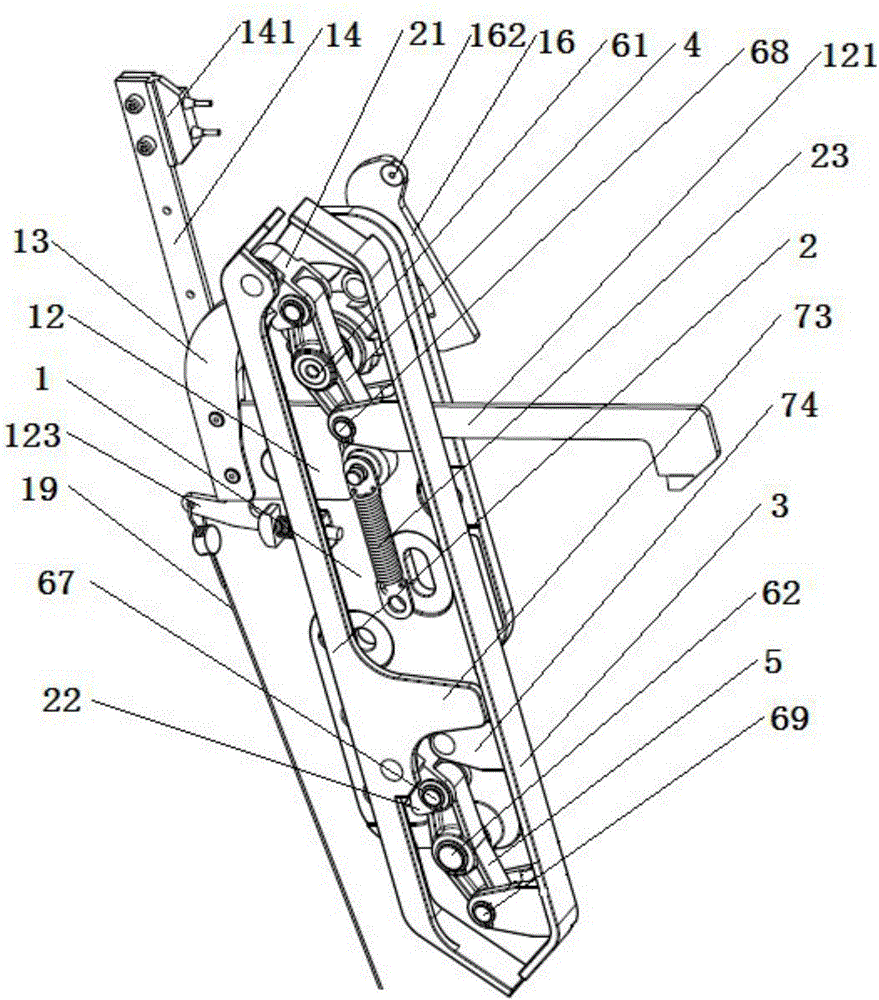

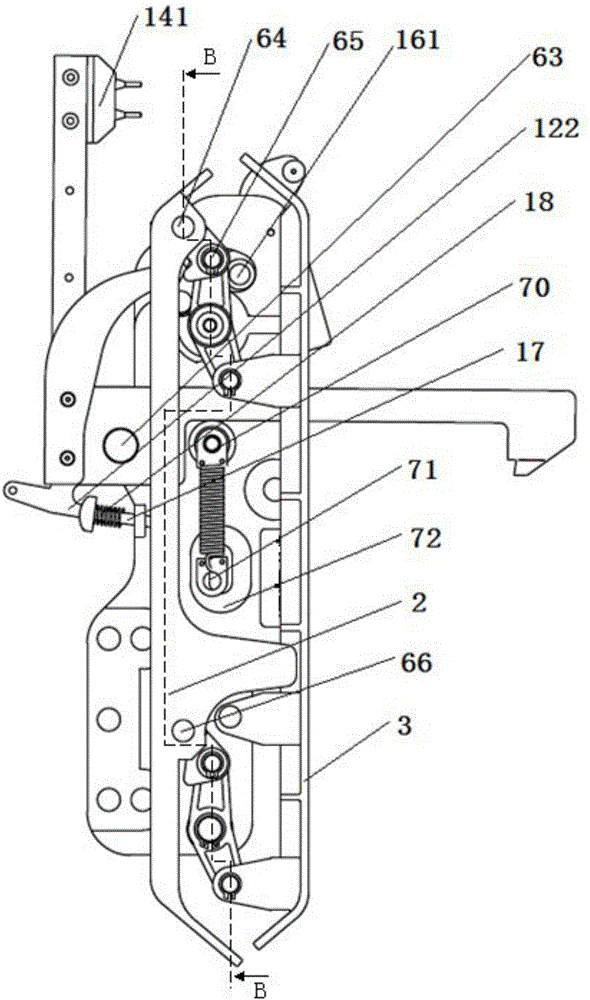

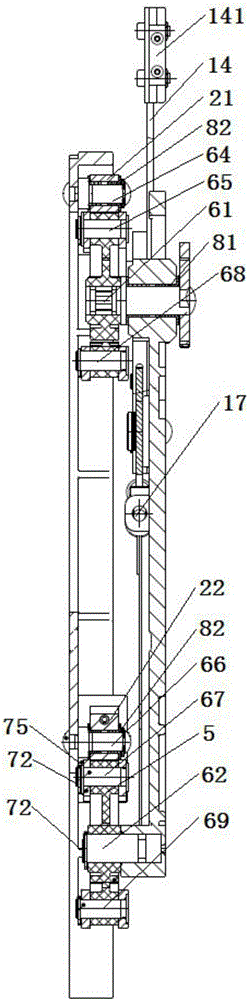

[0035] Such as figure 1Shown is a preferred three-dimensional structure diagram of the present invention, including base plate 1, left knife arm 2, right knife arm 3, upper connecting rod 4, lower connecting rod 5, and described base plate 1 is provided with upper connection hole and lower connecting hole arranged up and down connecting hole, the upper connecting rod 4 is movably connected to the upper connecting hole through the first connecting shaft 61, the lower connecting rod 5 is movably connected to the lower connecting hole through the second connecting shaft 62, and the upper The two ends of the connecting rod 4 are movably connected to the left knife arm 2 and the right knife arm 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com