Hanging method during hard chromium electroplating of bolt product

A technology of electroplating hard chrome and bolts, applied in jewelry and other directions, can solve the problems of waste of insulating materials, low production efficiency, low qualification rate, etc., and achieve the effect of saving tooling, improving production efficiency, and improving the qualification rate of one-time inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

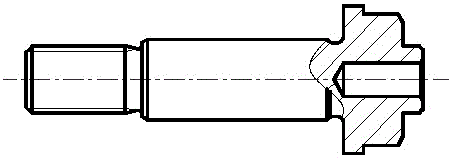

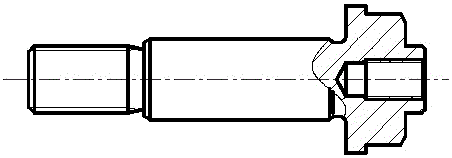

[0024] Such as figure 1 , 2 As shown, if the head of the bolt product itself has a lightening hole, the lightening hole on the head should be improved, and the ordinary lightening hole should be designed as a threaded hole with an internal thread;

Embodiment 2

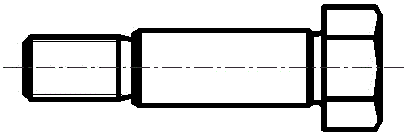

[0026] Such as image 3 , 4 As shown, if the bolt head does not have a relief hole, add a process section, and design the process section as a threaded hole with an internal thread, such as Figure 5 . The key of this technical solution lies in the cooperation of the precision grades of the threaded holes.

[0027] The present invention can also be used for electroplating hard chrome treatment of pins and shafts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com