Combined retaining structure and construction method thereof

A technology of retaining structure and construction method, which is applied in the direction of foundation structure engineering, underwater structures, excavation, etc., and can solve the problems of compaction of filled soil behind walls, large differential settlement of panels and reinforced soil, and small panel rigidity, etc. To meet the requirements of reducing the bearing capacity of the foundation and settlement control, homogenize and reduce the horizontal deformation of the wall, and prevent the filling from extrusion or local slump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawings and examples of implementation.

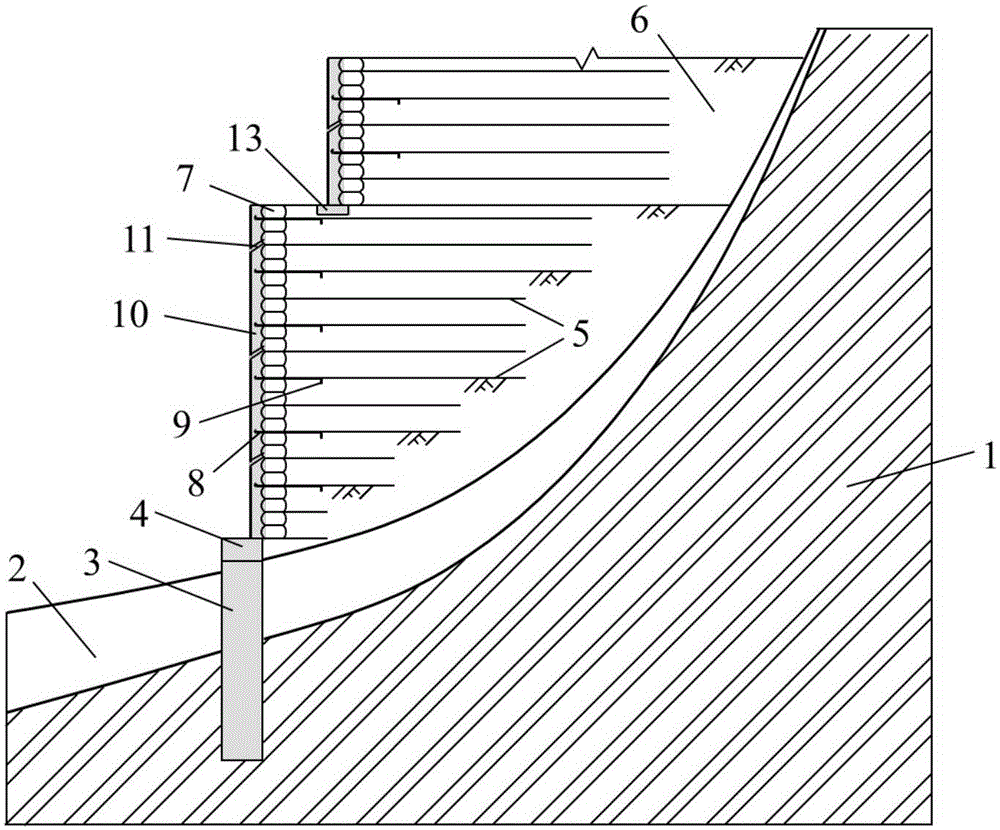

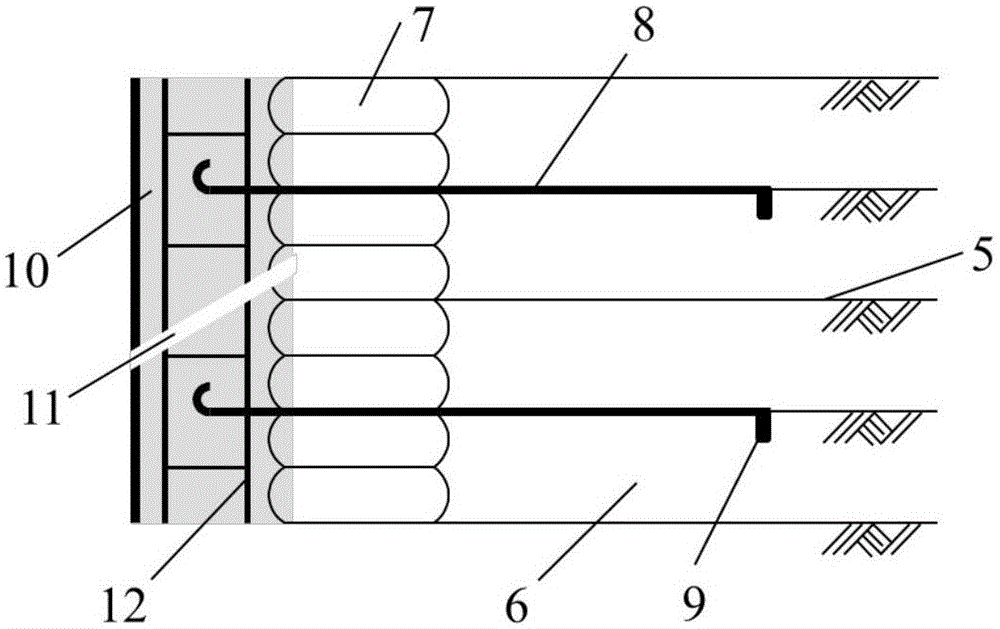

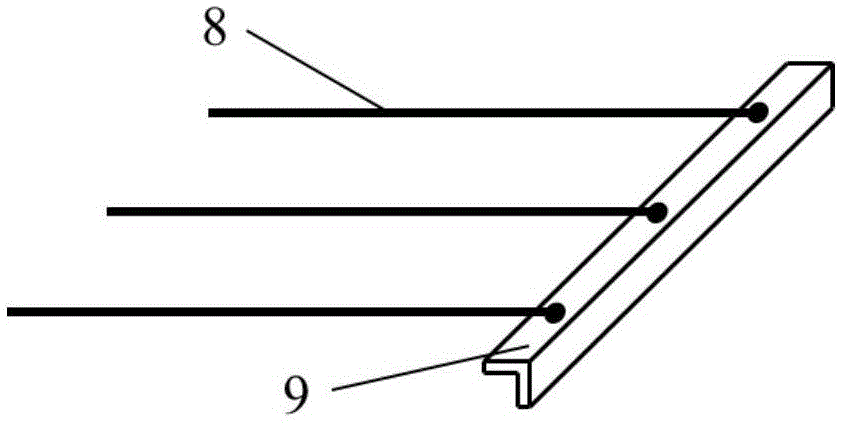

[0034] A combined retaining structure, such as Figure 1 ~ Figure 3 As shown, it includes anti-slide pile 3, connecting beam 4, reinforced soil retaining wall (composed of geogrid 5, filling soil 6 and bagged gravel 7), rigid panel (composed of cast-in-place concrete slab 10, drainage Holes 11 and reinforcement mesh 12 are jointly formed) and connecting member (comprising anchor reinforcement bar 8 and angle steel 9). The anti-slide pile 3 penetrates the covering soil layer 2 and is anchored in the stable stratum 1; the connecting beam 4 is located on the top of the anti-sliding pile 3, and the bottom of the beam is in contact with the covering soil layer 2; the reinforced soil retaining wall is a turn-up geogrid Reinforced earth retaining wall, the wall is made of bagged crushed stones, which can be constructed in stages; the rigid panel is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

| Ultimate tensile strength | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com