Vortex flow guiding device

A diversion device and eddy current technology, applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc., can solve the problems of large pressure loss of oil pipes, reduced liquid drainage capacity, poor drainage and gas production effectiveness, etc. The effect of pressure loss, improved drainage capacity and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with drawings and embodiments. However, those skilled in the art should know that the present invention is not limited to the specific embodiments listed, as long as it conforms to the spirit of the present invention, it should be included in the protection scope of the present invention.

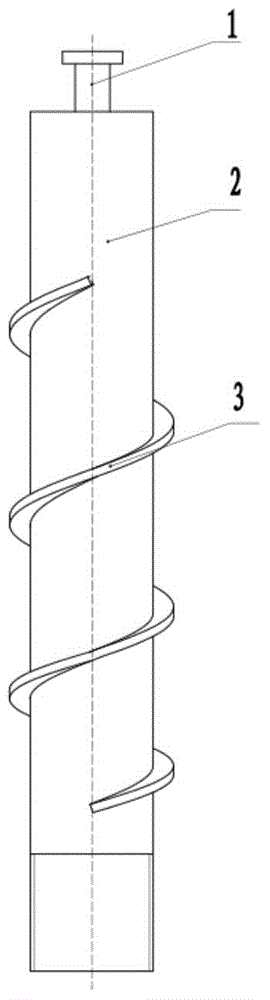

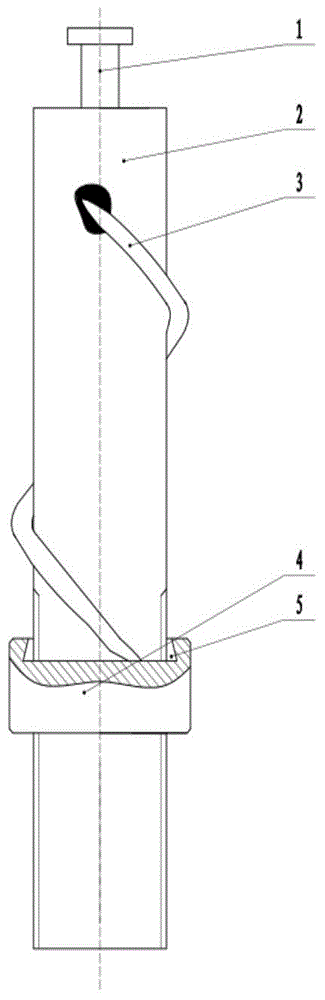

[0013] The eddy current diversion device of the present invention comprises a mandrel 2 and a diversion belt 3, and the diversion belt 3 is spirally wound on the outer surface of the mandrel 2; the upper end of the mandrel 2 has a fishing head 1, and the lower end has a drainage and gas collection The thread for connecting the downhole device; usually the cross section of the diversion zone 3 is rectangular.

[0014] The pitches between the guide belts 3 of the first embodiment of the eddy current guide device of the present invention are not equal, that is, the pitches between the adjacent guide belts 3 spirally wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com