Transfer case of a core drilling rig

A technology of core drilling rig and transfer case, which is applied in the field of core drilling rig and transfer case, which can solve the problems that the transfer and speed change of gyrators and winches cannot meet the speed requirements well, and achieve good transfer and speed change effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

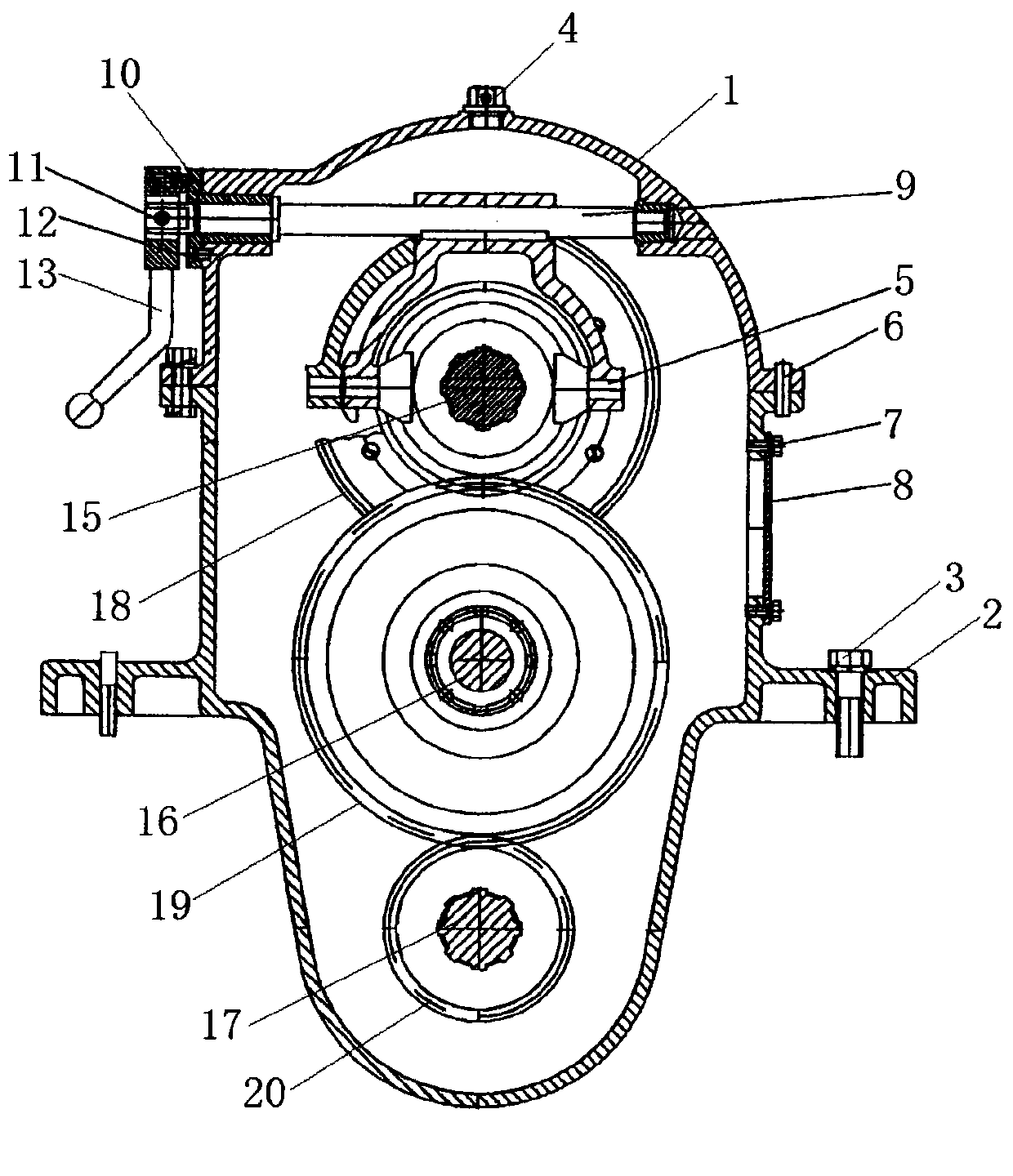

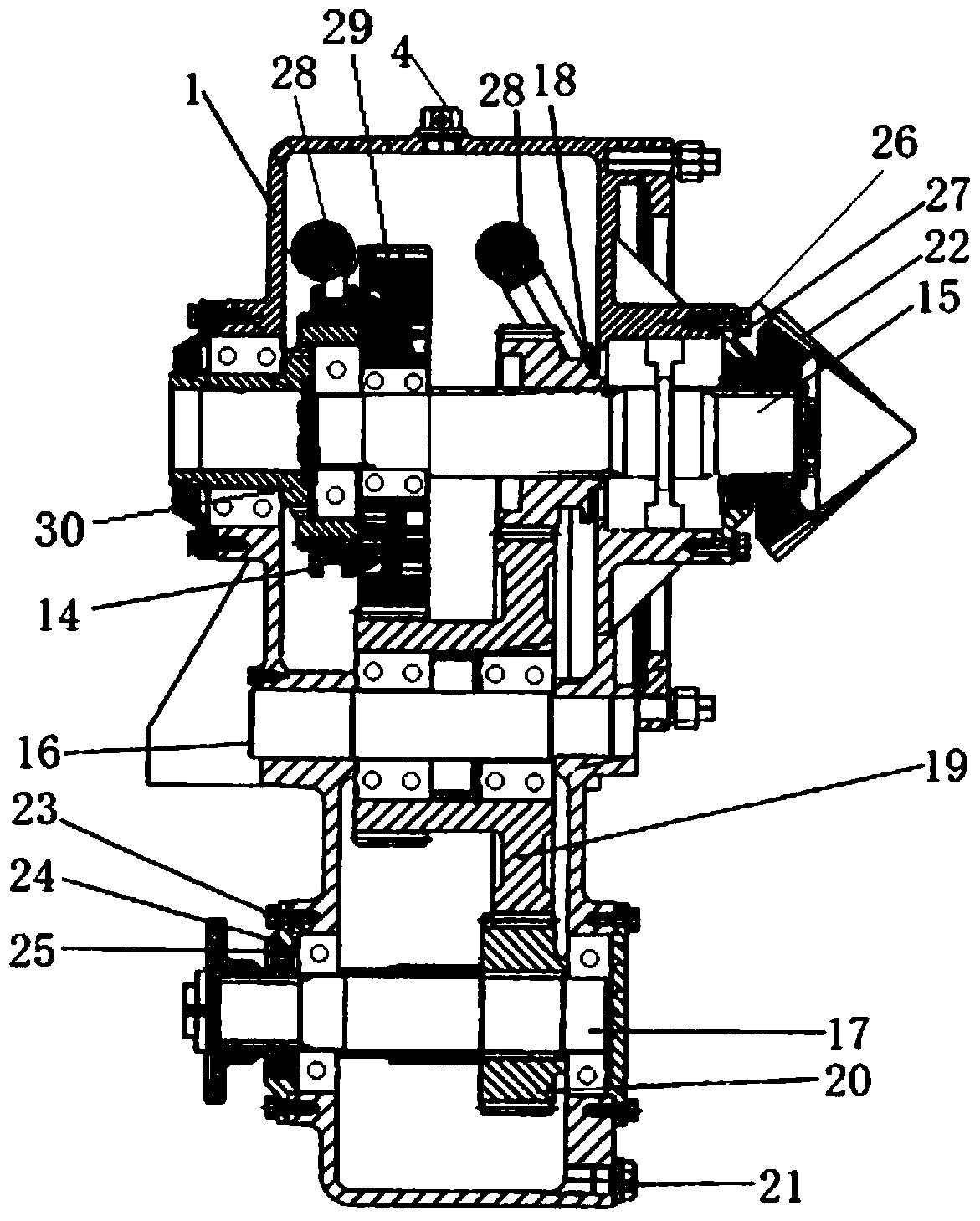

[0017] Such as figure 1 and figure 2 As shown, a transfer case of a core drilling rig comprises a case body 1. The case body 1 includes an upper case body and a lower case body. Fixed connection. The support plate 2 that both sides of the lower casing have is installed on the front frame of the drilling rig by the first bolt 3 . The upper box body is provided with a vent plug 4, and the lower box body is provided with an oil plug 21. The side wall of the lower box above the support plate 2 is provided with a port, and the port is sealed and installed by the cover plate 8 and the second bolt 7 .

[0018] A shift fork shaft 9 is inserted into the upper part of the case, and the two ends of the shift fork shaft 9 are installed on the case through bearing sleeves 10, and one end of the shift fork shaft 9 located outside the case is connected with a handle 13 through a cylindrical pin 11. The bearing sleeve is fixed on the casing by countersunk head screws 12. A shift fork 28...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com