Novel stepless speed change device

A continuously variable transmission device, a new type of technology, applied in transmission devices, friction transmission devices, belts/chains/gears, etc., can solve the problems of large force on the gearbox case, achieve large transmission torque, ensure reliability, and drive high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

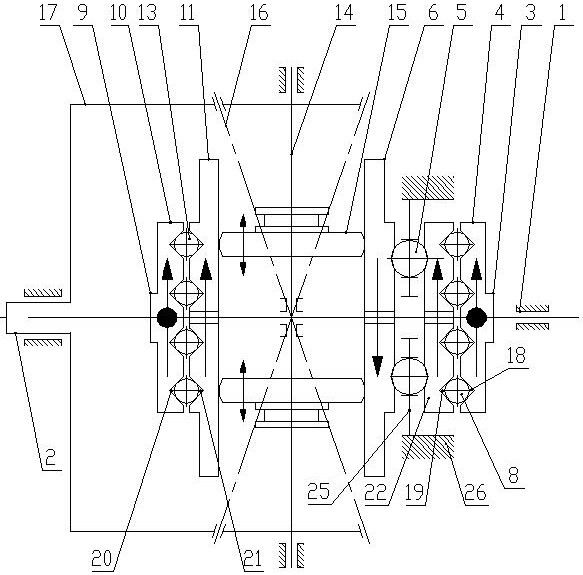

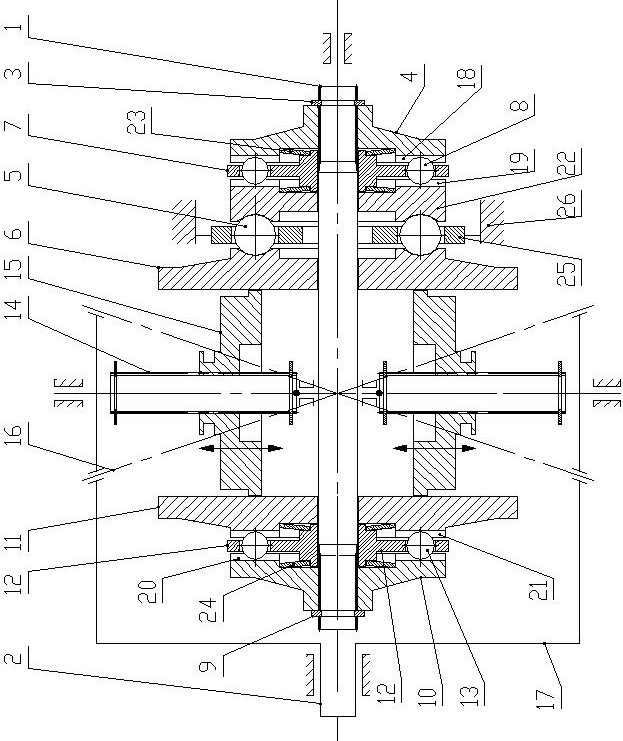

[0017] like figure 1 and figure 2 As shown, a novel continuously variable transmission device of the present invention includes an input shaft 1 and an output shaft 2 arranged along the left and right directions, the input shaft 1 is located on the left side of the output shaft 2, and the left side and the right side of the input shaft 1 are respectively provided with The left automatic pressurization mechanism and the right automatic pressurization mechanism are respectively driven between the left automatic pressurization mechanism and the right automatic pressurization mechanism on the front and rear sides of the input shaft 1. There is a radial sliding output mechanism with a roller position, and two rollers The power output end of the position radial sliding output mechanism is connected with the output shaft 2 through transmission.

[0018] The left automatic pressurization mechanism includes the first lock nut 3, the first pressure plate 4, the first rolling torque tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com