A reciprocating screen slot automatic transmission device

An automatic transmission and reciprocating technology, which is applied in the direction of transmission, transmission control, and components with teeth, can solve the problems affecting the quality of cigarettes, waste, shredded tobacco, etc., to improve automation performance and reduce push Strength, the effect of increasing the pushing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

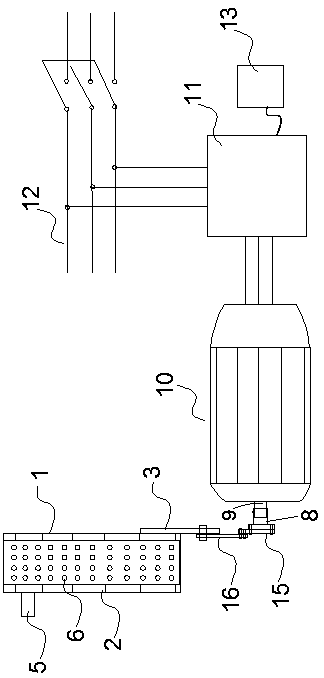

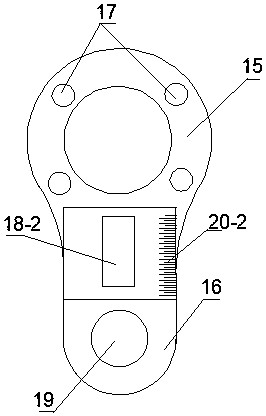

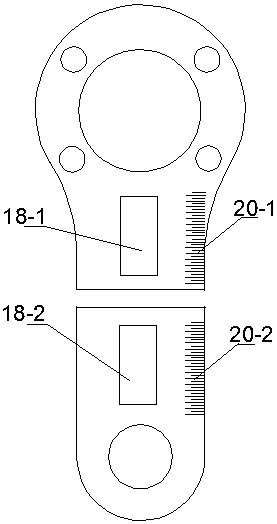

[0018] Such as figure 1 , 2 , 3, 4 and Figure 5 As shown, the present invention includes a mechanical transmission mechanism and a circuit control mechanism, the mechanical transmission mechanism includes a motor 10, the output shaft 9 of the motor 10 is sleeved with a connecting flange 8, and the connecting flange 8 includes a flange plate and a flange neck , the flange neck is provided with a pin hole 4, and is equipped with a pin; the upper part of the first precision adjustment transmission plate 15 is provided with a screw hole 17 corresponding to the mounting hole on the flange plate, and the first precision is fixed by the bolt. The top of the adjustment drive plate 15 is fixed with the flange. The lower adjustment end of the first accuracy adjustment transmission plate 15 is connected to the upper adjustment end of the second accuracy adjustment transmission plate 16, and the lower adjustment end of the first accuracy adjustment transmission plate 15 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com