Method for crossed crossing construction of composite hose

A composite hose and cross-over technology, which is applied in the field of submarine composite hose cross-over, can solve problems such as difficulty, large sea workload, and large operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

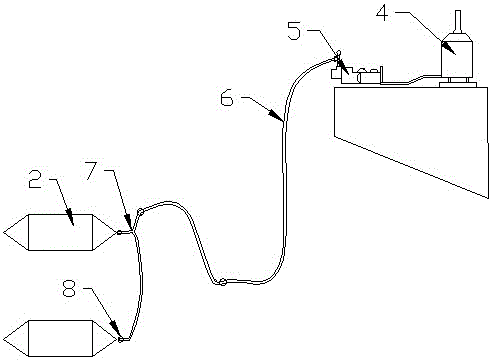

[0029] A composite hose cross-spanning construction method described in the embodiment of the present application includes the following steps:

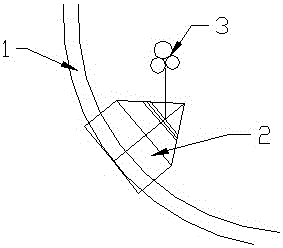

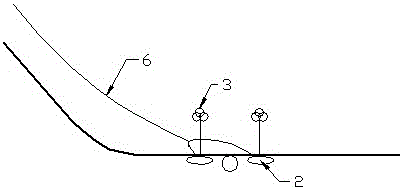

[0030] S1. Accurately measure and determine the binding position of the grouting airbag 2;

[0031] S2. Recover the composite hose 1 and bind the grouting airbag 2 at a suitable position;

[0032] S3. The composite hose 1 is put in place again to carry out the grouting operation and complete the composite hose crossover process.

[0033] Wherein, in this embodiment, the determination method of the step S1 is as follows:

[0034] During the laying of the composite hose 1, according to the water depth of the operating sea area, when the mud entry point of the composite hose 1 is about 100-300m away from the crossing point, draw a line on the hose body at a distance of 0.5m, and the length of the line is 150m. , Continue to lower the composite hose 1 When it crosses the original submarine pipeline for about 20-30 meters, stop the layi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Pressure endurance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com