A Kink Resistance Detection System for Air Filling Hose

A technology of anti-kink and detection equipment, applied in pipeline systems, measuring devices, gas/liquid distribution and storage, etc., can solve problems such as cracks in the gas filling hose, affecting the gas filling work of the gas filling machine, rupture, etc., to simplify the fixation. method, realize automatic remote monitoring, and ensure the effect of security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

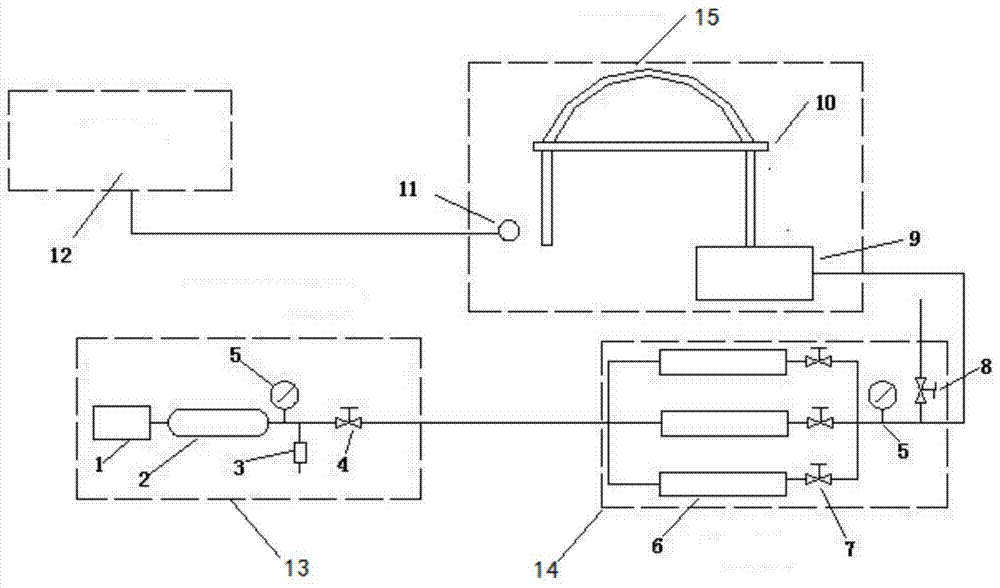

[0014] Such as figure 1 As shown, a gas filling hose kink resistance detection system includes an air source generating device 13, a pressure regulating device 14, an anti-kink detection device 15 and a monitoring device 12, and the output end of the gas source generating device 13 is connected to the pressure regulating device 14 , the anti-kink detection device 15 is used to connect the pressure regulating device 14, the gas source generating device 13 includes a compressor 1, the compressor 1 is connected with the gas storage container 2, the output end of the gas storage container 2 is connected with a shut-off valve 4, and the gas storage container A safety valve 3 and a pressure gauge 5 are provided between 2 and the cut-off valve 4 . The pressure regulating device 14 includes a pressure stabilizing valve 6, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com