Measurement and representation method for softness of tobacco leaves

A technology of softness and tobacco leaves, which is applied in the field of measurement and characterization of tobacco leaf softness, can solve the problems of relying on manual identification and cannot quantitatively measure the softness of tobacco leaves, etc., achieve objective measurement results, solve the problem of inability to quantitatively characterize, and standardize the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

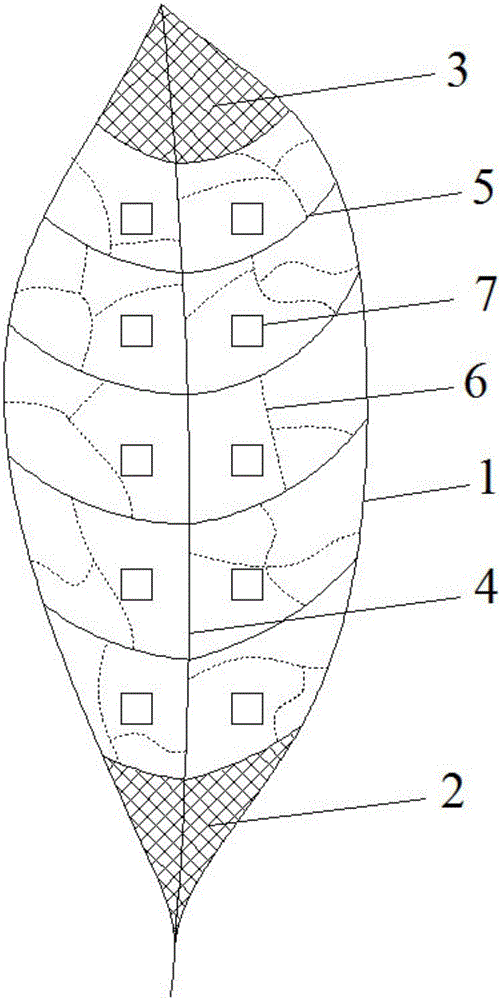

Image

Examples

example 1

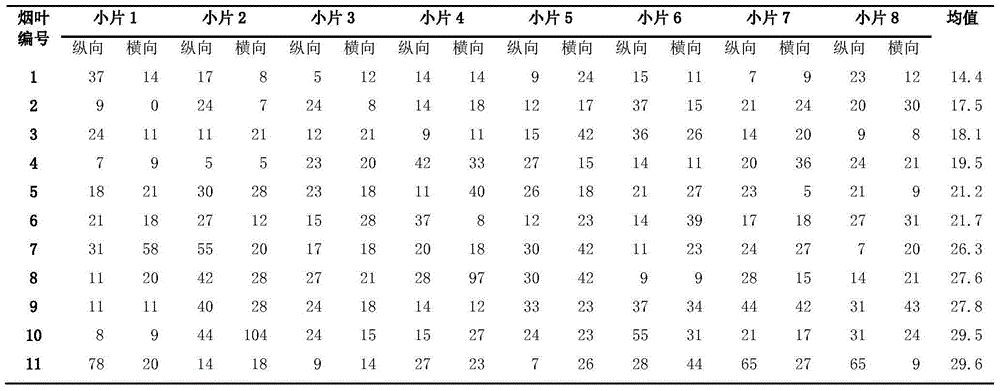

[0043] The actual measurement of example one tobacco leaf softness

[0044] 1. 11 pieces of complete first-cured tobacco leaves as test materials

[0045] 2. The test method is carried out according to the given method and steps of the present invention.

[0046] 3. The test results are shown in Table 1.

[0047] Table 1 Tobacco leaf softness measurement results (unit: mN)

[0048]

example 2

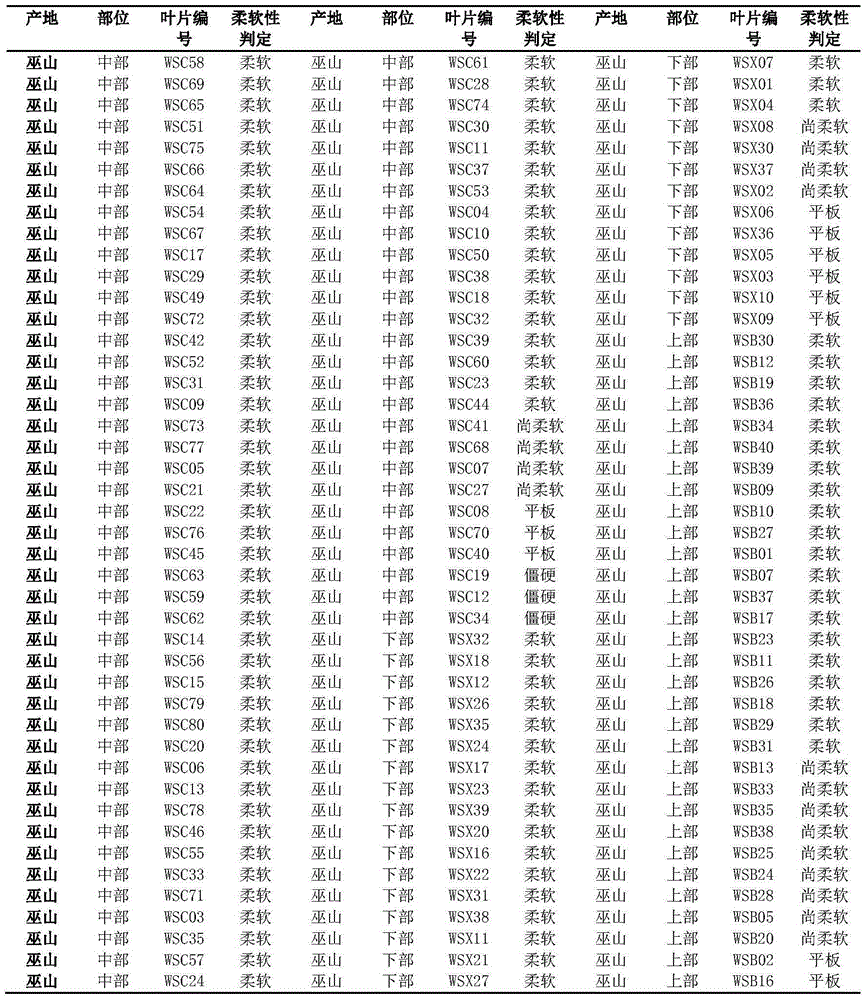

[0049] Example 2: Test of distribution characteristics of softness measurement values of tobacco leaves with different softness

[0050] 1. Preparation of test materials: one batch of mixed tobacco samples containing upper, middle and lower tobacco leaves in Hefeng County of Hubei Province and Wushan County of Chongqing in 2013

[0051] 2. Test purpose and method

[0052] Learn about the correspondence between tobacco leaf softness and tobacco leaf softness measurements.

[0053] The softness of the samples to be tested is judged piece by piece by double-blind method, and the softness value is measured.

[0054] 2.1 Qualitative judgment of the softness (hand feel) of the sample:

[0055] The two batches of samples were divided into upper leaves, middle leaves, and lower leaves according to their parts, and each batch of samples was divided into three groups, a total of six groups; the softness evaluation team composed of 6 appearance rating experts for each group of tobacco ...

example 3

[0081] Example 3 Reliability Test of Tobacco Leaf Softness Measurement Value Predicting Tobacco Leaf Softness

[0082] 1. Preparation of test materials: Select 100 pieces of mixed samples from Huidong in Sichuan, Ankang in Shaanxi, Sangzhi in Hunan, Lichuan in Hubei, Zhaotong in Yunnan, and Bijie in Guizhou, remove incomplete leaves, and set aside.

[0083] 2. Test purpose and method

[0084] To verify the reliability of predicting the softness of tobacco leaves by using the softness value and its grade classification method; the test adopts a double-blind method, and two independent research groups conduct softness prediction and softness actual judgment respectively, and then compare the results, and the calculation prediction is accurate Rate.

[0085] 2.1 Determination of softness of test samples

[0086] Measured piece by piece of tobacco leaf according to the method specified in the present invention.

[0087] 2.2 Prediction of softness of test samples

[0088] Carry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com