Ring-shaped metal part counting device

A technology of metal parts and counting devices, which is applied in the field of parts counters, can solve the problems of poor counting accuracy and low work efficiency, and achieve the effects of high work efficiency, reduced labor intensity and high counting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

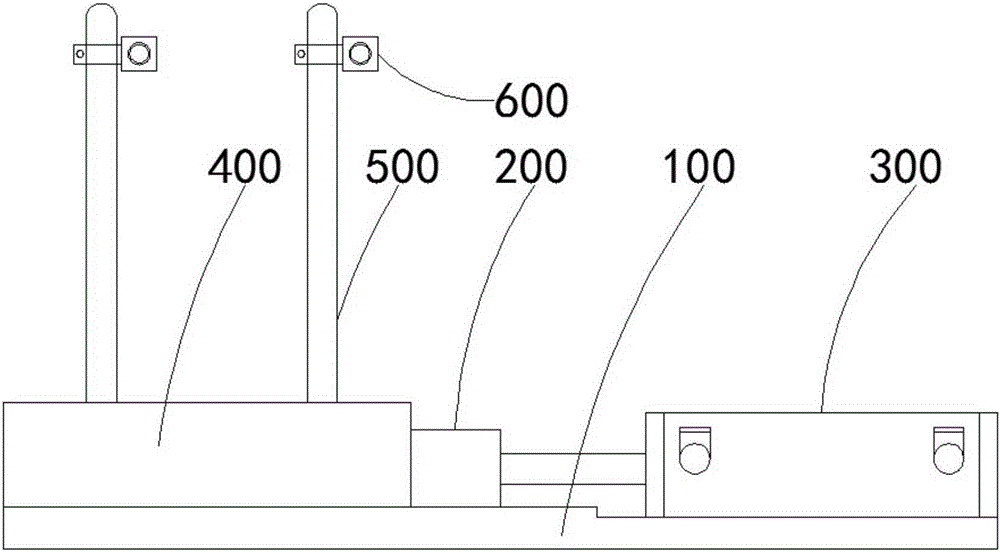

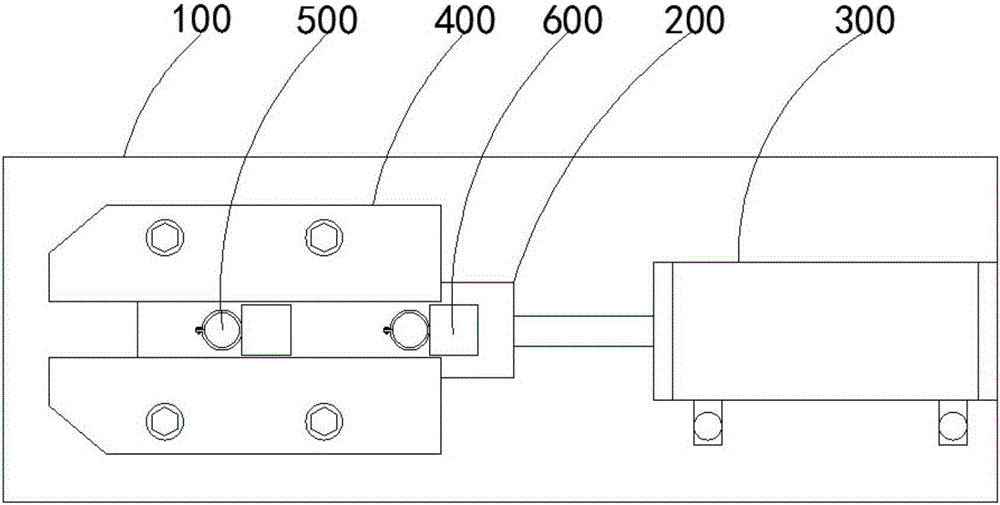

[0036] For the first embodiment, refer to Figure 1-2 , the annular metal parts counting device includes a base plate 100, on which a slide plate 200, a driving device for driving the slide plate 200 to reciprocate in a straight line, and a limiting structure for limiting the movement direction of the slide plate 200 are arranged on the base plate 100, so The slide plate 200 is in the shape of a long strip and is provided with two columns 500, the two columns 500 are perpendicular to the slide plate 200, and the two columns 500 are provided with a photoelectric sensor 600 for measuring the quantity of ring-shaped metal parts. The photoelectric sensor 600 is connected with a controller for controlling the start and stop of the driving device.

[0037] Wherein, the base plate 100 is a rectangular plate, and its four corners are provided with installation holes so that it can be installed in various environments; Transition to ensure the smoothness of sliding; the two columns 50...

no. 2 example

[0048] The second embodiment, the device provided by the embodiment of the present invention, its realization principle and the technical effect produced are the same as those of the previous embodiment. For brief description, for the parts not mentioned in the device embodiment, please refer to the corresponding content in the previous embodiment .

[0049] In this embodiment, the driving device is a hydraulic cylinder, the hydraulic cylinder is connected to a solenoid valve, the solenoid valve is connected to a hydraulic pump, the hydraulic pump is connected to a hydraulic oil tank, and the controller is connected to the solenoid valve .

[0050] Wherein, the hydraulic cylinder is a hydraulic actuator that converts hydraulic energy into mechanical energy and performs linear reciprocating motion (or swing motion). The piston rod of the hydraulic cylinder is detachably connected to the slide plate 200 at one end outside the cylinder The hydraulic pump is the power component o...

no. 3 example

[0052] The third embodiment, the implementation principle and technical effect of the device provided by the embodiment of the present invention are the same as those of the previous embodiment. For a brief description, for the parts not mentioned in the device embodiment, please refer to the corresponding content in the previous embodiment .

[0053] In this embodiment, the driving device includes a rack that is slidably connected to the bottom plate 100, a gear meshed with the rack, and a motor for driving the gear to rotate. One end of the rack is connected to the The skateboard 200 is connected, the motor is arranged on the bottom plate 100, and the controller is connected with the motor.

[0054] Wherein, linear limit bars are arranged on both sides of the rack to ensure that the rack moves in a straight line; the teeth of the rack and the gear are helical teeth to improve the stability and reliability of the transmission; The motor is a stepping motor, and the stepping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com