Intelligent filling type communication cabinet

A communication chassis, intelligent filling technology, applied in the direction of the chassis/cabinet/drawer parts, the circuit layout on the support structure, etc., can solve the problems of inconvenient movement, shaking of communication equipment, damage of communication equipment, etc., to ensure stability performance, avoid damage, and facilitate maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

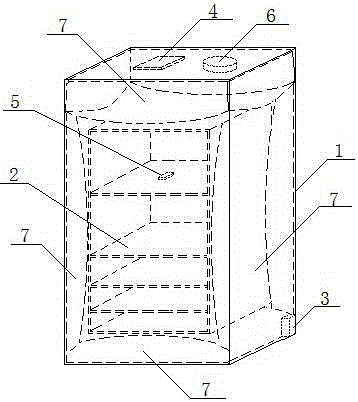

[0017] Such as figure 1 As shown, the present invention designs a kind of intelligent filling type communication case, comprises communication case body 1, and the equipment frame 2 and power supply module 3 that are arranged in communication case body 1, power supply module 3 connects external power supply to take power; Also Include control module 4, and the acceleration sensor 5 that is connected with control module 4, micro-pump 6 respectively; The sensor 5 is fixedly arranged at any position inside the communication case body 1; the top surface, the bottom surface, and each side wall in the communication case body 1 are respectively provided with elastic airbags 7, and the micro air pump 6 is arranged inside the communication case body 1, and the micro air pump The nozzle of 6 is connected with the air inlet and ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com