A logic conversion circuit device

A logic conversion and circuit device technology, applied in the direction of cabinet/cabinet/drawer parts, cooling/ventilation/heating transformation, etc., can solve the problem of poor operability, small force, and inability to close the front cover Board performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, content of the invention will be further described:

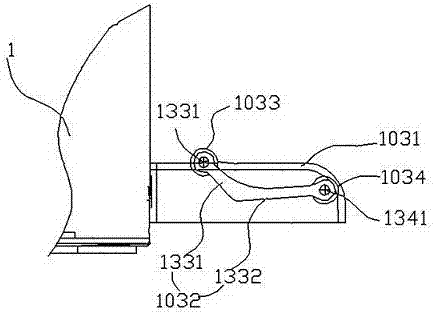

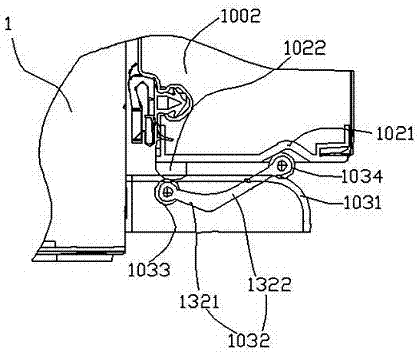

[0025] refer to figure 1 , figure 2 , image 3 and Figure 4As shown, the logic conversion circuit device includes a logic conversion circuit, and the logic conversion circuit is placed in a radiator. In addition, the radiator is a hollow cabinet 1, and the cabinet 1 has a cooling pipe inside. The logic conversion circuit is set in the cabinet body, and the cabinet body 1 has a refrigerant inlet and a refrigerant outlet connected to the heat dissipation pipe, and the refrigerant enters through the refrigerant inlet and the refrigerant outlet allows the refrigerant to flow out In this cycle, the heat generated by the logic conversion circuit is taken away. In addition, the cabinet 1 includes a front cover 1002 and a front cover attachment 1003. The front cover 1002 is opened when the cabinet 1 is opened. Between the opening position and the closing position of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com