A tobacco leaf treatment method for prolonging the alcoholization period of laminar tobacco

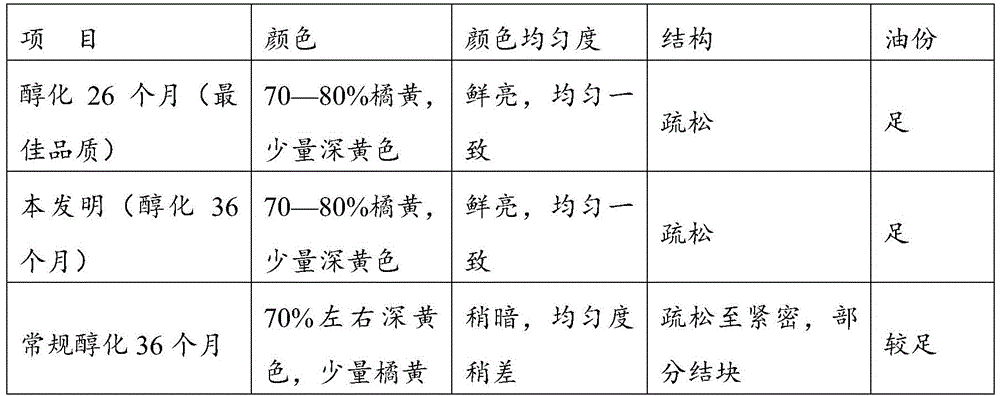

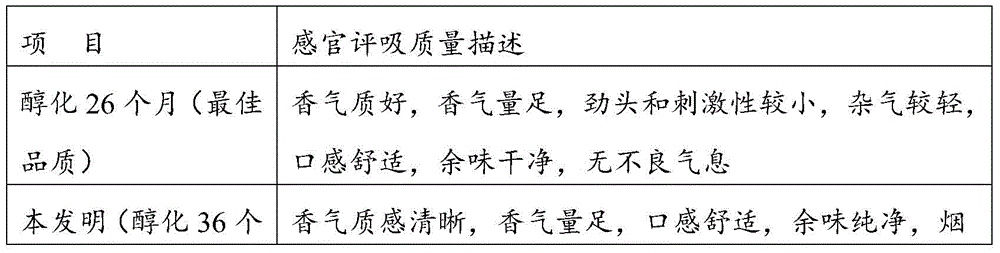

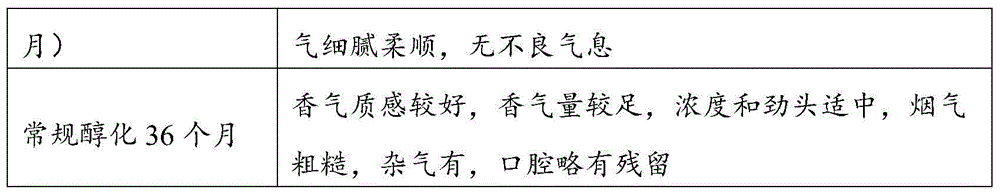

A treatment method and aging technology, applied in the treatment of tobacco, tobacco, application, etc., can solve the problems of missing the best use period of tobacco leaf quality, increasing the metabolic consumption of tobacco leaves, increasing the production cost of cigarettes, etc., achieving no bad smell, sensory evaluation, etc. The effect of better suction quality and clear aroma texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A method for processing tobacco leaves for prolonging the alcoholization period of sheet tobacco, comprising the steps of:

[0014] The first step is to clarify the stock quantity of C2F grade laminar tobacco in the middle part, and deal with it case by case. (1) Open the box by box, untie the lining bag of the packaged cigarettes in the cigarette box; (2) vacuumize the lining bag and fill it with CO 2 Gas, so cycled twice, sealed tightly; (3) repack the smoke box, use sealing tape to seal the upper and lower seals of the smoke box.

[0015] The second step is to transfer the above-mentioned sealed smoke boxes to a well-equipped warehouse, control the temperature and humidity, and require a temperature of 10 degrees and a humidity of 45%. When the smoke boxes are transferred to a new warehouse area, the smoke boxes are required to be stacked in a single layer to avoid Multi-layer extrusion.

[0016] In the third step, after 10 months of alcoholization of the batch of ...

Embodiment 2

[0018] A method for processing tobacco leaves for prolonging the alcoholization period of sheet tobacco, comprising the steps of:

[0019] The first step is to clarify the stock quantity of C2F grade laminar tobacco in the middle part, and deal with it case by case. (1) Open the box by box, untie the lining bag of the packaged cigarettes in the cigarette box; (2) vacuumize the lining bag and fill it with CO 2 Gas, so cycled 3 times, sealed tightly; (3) repack the smoke box, use sealing tape to seal the upper and lower seals of the smoke box.

[0020] The second step is to transfer the above-mentioned sealed smoke boxes to a well-equipped warehouse, control the temperature and humidity, and require a temperature of 15 degrees and a humidity of 50%. When the smoke boxes are transferred to a new warehouse area, single-layer stacking of the smoke boxes is required to avoid Multi-layer extrusion.

[0021] In the third step, after 10 months of alcoholization of the batch of cigare...

Embodiment 3

[0023] A method for processing tobacco leaves for prolonging the alcoholization period of sheet tobacco, comprising the steps of:

[0024] The first step is to clarify the stock quantity of C2F grade laminar tobacco in the middle part, and deal with it case by case. (1) Open the box by box, untie the lining bag of the packaged cigarettes in the cigarette box; (2) vacuumize the lining bag and fill it with CO 2 Gas, so cycled twice, sealed tightly; (3) repack the smoke box, use sealing tape to seal the upper and lower seals of the smoke box.

[0025] In the second step, the above-mentioned sealed smoke box is transferred to a well-equipped warehouse, and the temperature and humidity are controlled, requiring a temperature of 20 degrees and a humidity of 55%. When the smoke boxes are transferred to the new warehouse area, the smoke boxes are required to be stacked in a single layer to avoid multi-layer extrusion.

[0026] The fourth step, after 10 months of alcoholization of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com