A tooth scaler handle

A dental scaler and handle technology, applied in the field of medical machinery, can solve the problems of short circuit, inconvenient operation, and high operator requirements, and achieve the effects of safe use, good teeth cleaning effect, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

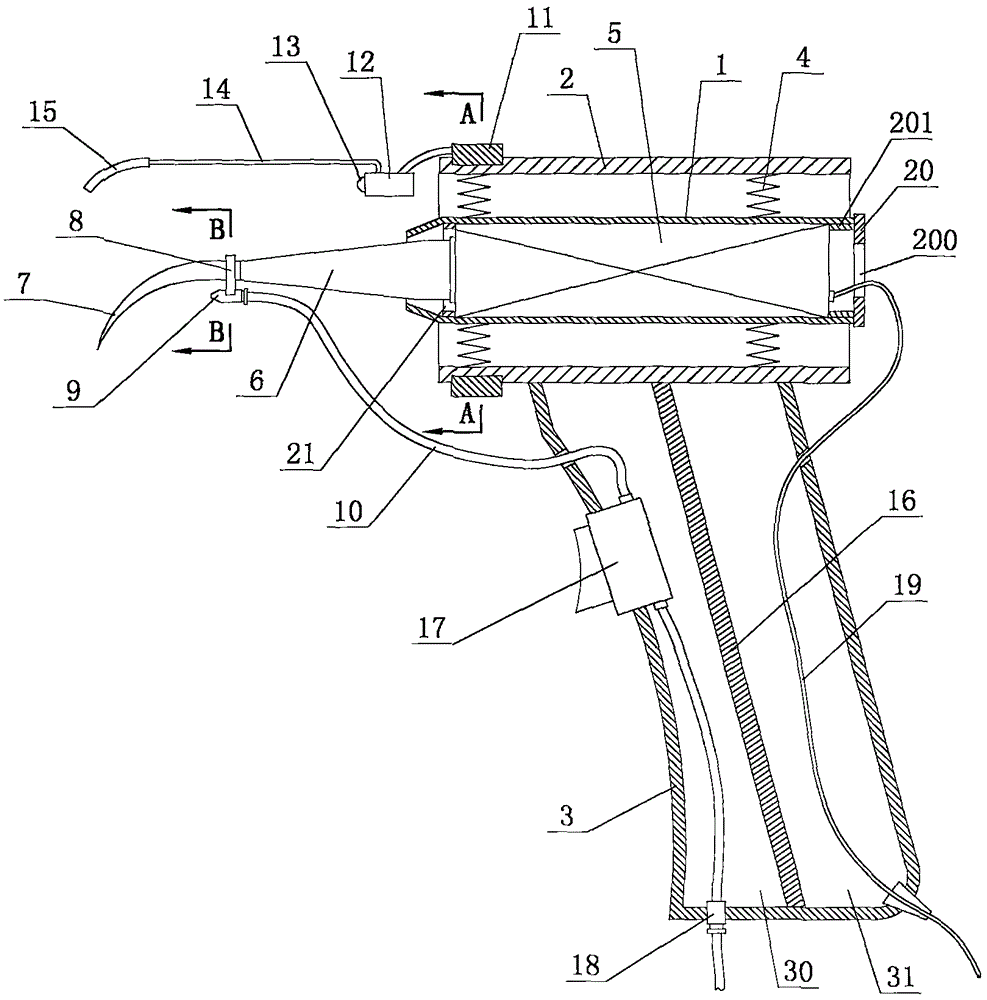

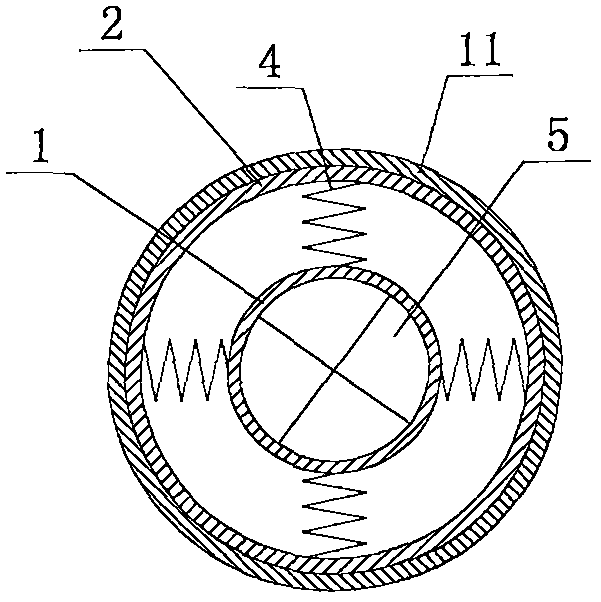

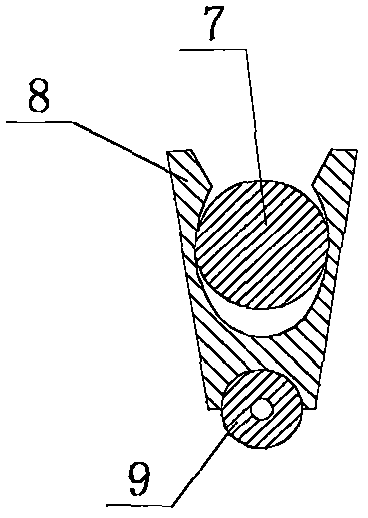

[0016] With reference to the accompanying drawings, the scaler handle of the present invention includes an inner cylinder 1 and an outer cylinder 2 sleeved outside the inner cylinder 1, the bottom of the outer cylinder 2 is connected with a handle 3, and the outer wall of the inner cylinder 1 is connected to the outer wall of the inner cylinder 1. A plurality of supporting springs 4 are connected between the inner walls of the outer cylinder 2, and an ultrasonic transducer 5 is fixedly installed in the inner cylinder 1, and the front end of the ultrasonic transducer 5 is connected to the horn 6, and the front end of the horn 6 extends Out of the inner cylinder 1 and connected to the working head 7 at the front end of the horn 6; the rear of the working head 7 is fitted with a water spray nozzle 9 with an opening facing forward through an elastic clip 8, and the rear end of the water spray nozzle 9 A water pipe 10 is connected; a rotating sleeve 11 is set on the front end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com