Fire-fighting hammer for fire-fighting safety

A fire hammer and safety technology, which is applied in the field of fire hammer for fire safety, can solve the problems of timely escape of unfavorable personnel, long crushing time, poor reliability, etc., and achieves simple structure, improved safety, good safety and reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be described in further detail below in conjunction with specific embodiments.

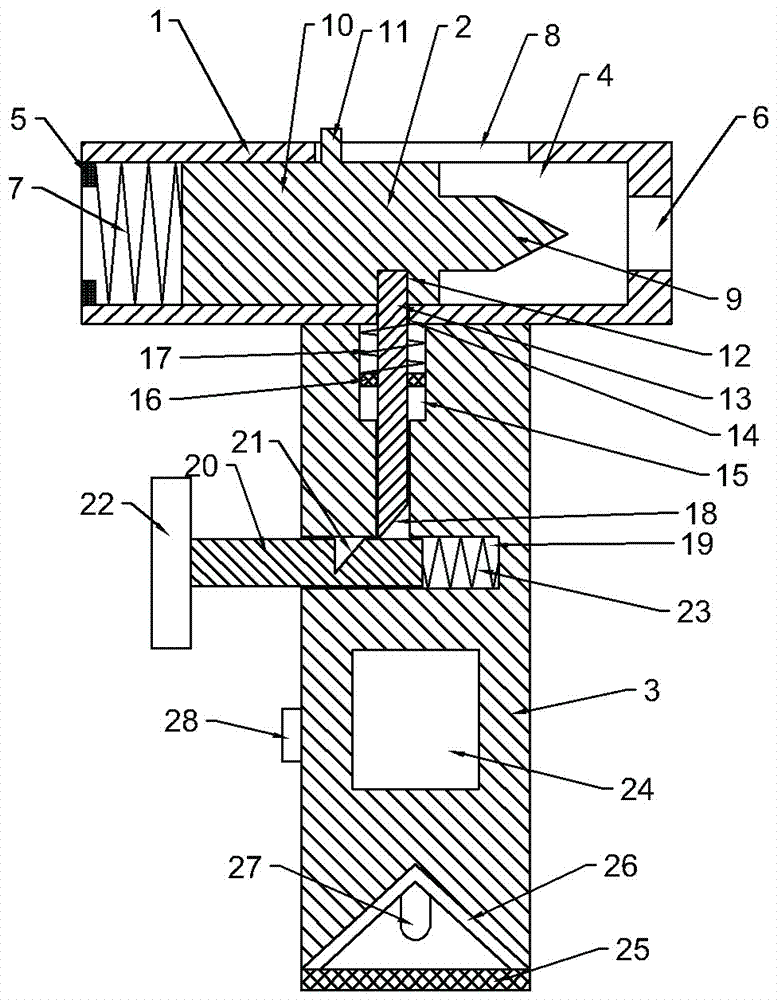

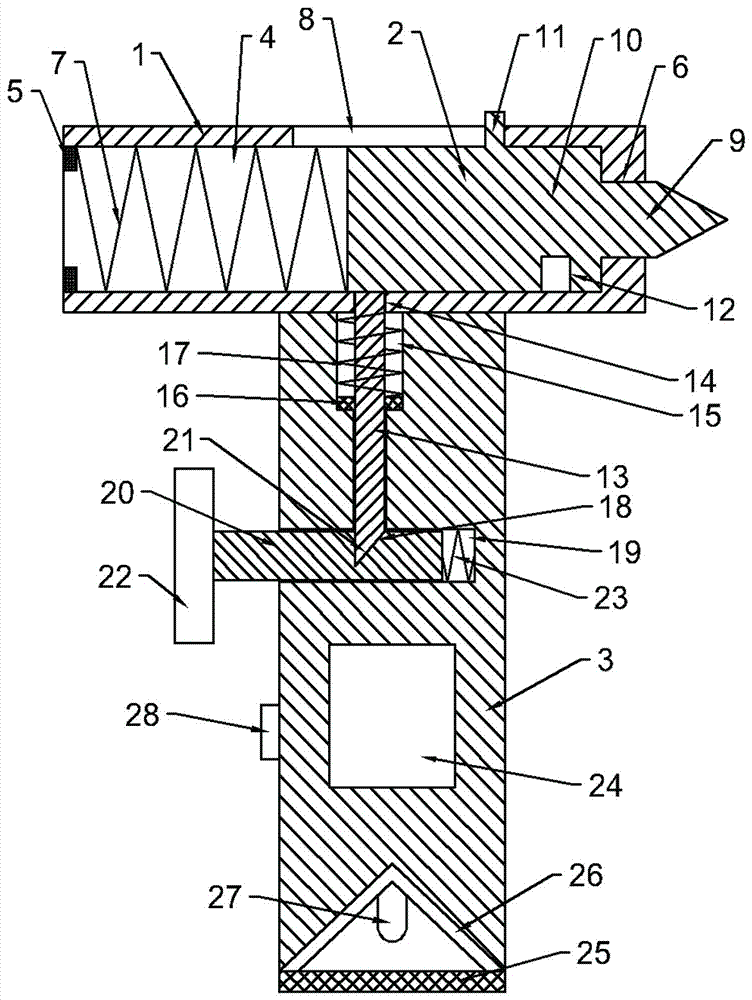

[0018] See Figure 1-2 , A fire hammer for fire safety, comprising a hammer body 1, a hammer head 2, and a hammer handle 3. The lower part of the hammer body 1 is connected to the hammer handle 3. The hammer body 1 is provided with an inner cylinder 4, and the left end of the inner cylinder 4 To be an open structure, the inner cylinder 4 is provided with a baffle ring 5 at the left end, which is screwed together with the hammer body 1. This structure improves the convenience of assembly; the inner cylinder 4 is provided with a through hole 6 at the right end, The inner cylinder 4 is provided with a first spring 7 in figure 1 In the middle state, the first spring 7 is in a compressed state, and the upper end of the hammer body 1 is also provided with a long hole 8 extending in the front and rear direction; the hammer head 2 is slidably arranged in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com