Hydraulic bending straightener

A straightening and hydraulic technology, which is applied in the field of hydraulic machinery, can solve the problems of heavy bending machines and cannot meet the needs of field operations, and achieve the effect of convenient and quick use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

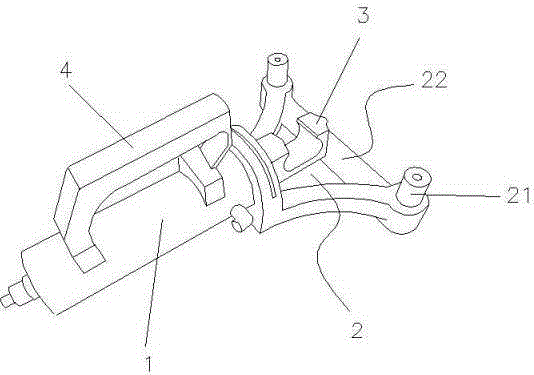

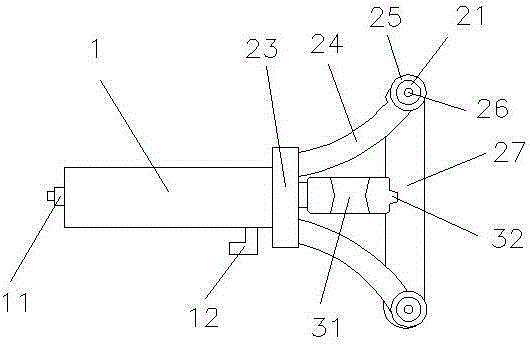

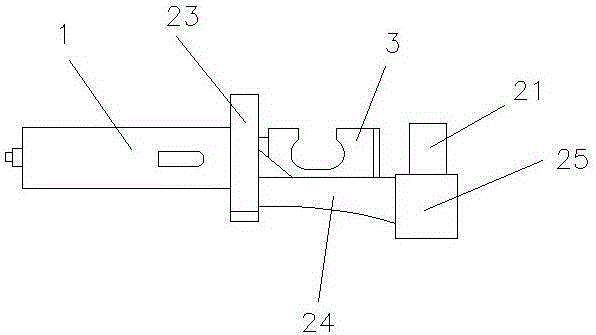

[0020] Embodiment: hydraulic bending straightener (see attached figure 1 , 2 , 3), including a hydraulic cylinder 1 and a bending assembly 2, the hydraulic cylinder 1 is fixedly connected to the bending assembly 2, the bending assembly 2 includes a bending frame 22 and a bending head 3, the bending The elbow 3 is fixedly connected with the hydraulic cylinder 2, the bending column 21 is arranged on the bending frame 22, the bending column 21 is fixedly connected with the bending frame 22, and the end of the bending head 3 is set Bending ribs 32, the bending ribs 32 are fixedly connected to the bending head 3, the bending groove 31 is set on the bending head 3, and the bending grooves 31 are arc-shaped on both sides Groove, the bending frame 22 includes a connecting seat 23 and a bending seat 25, a bending rod 24 is arranged between the bending seat 25 and the connecting seat 23, and one end of the bending rod 24 is connected to the bending The seat 25 is fixedly connected, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com