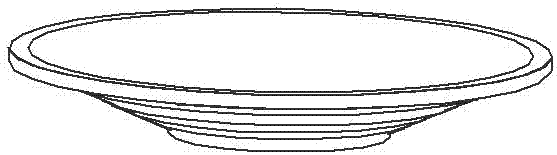

Rapid modeling tooling and rapid modeling method for large disc castings

A large-scale, disc technology, applied in the field of rapid molding tooling for large-scale disc castings, can solve the problems of complex mold making, high cost, long cycle, etc., and achieve the effect of simple molding method, large radius of gyration, and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

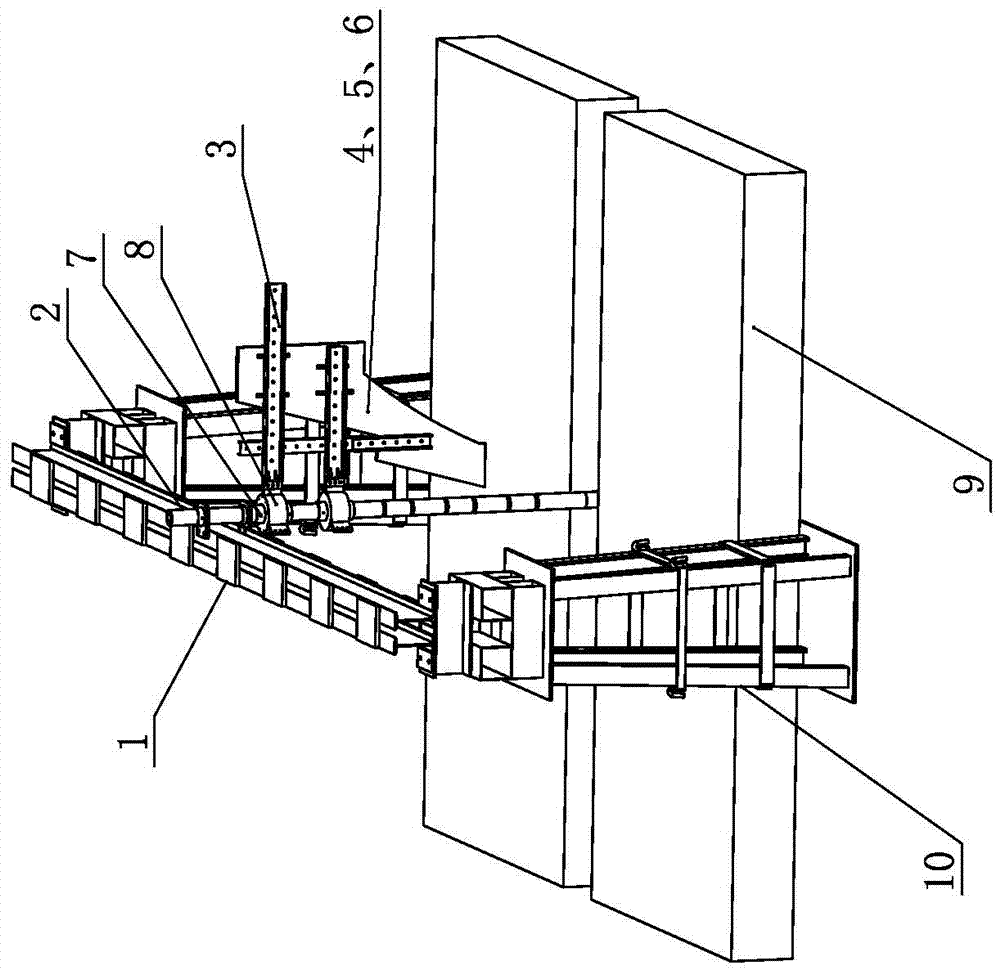

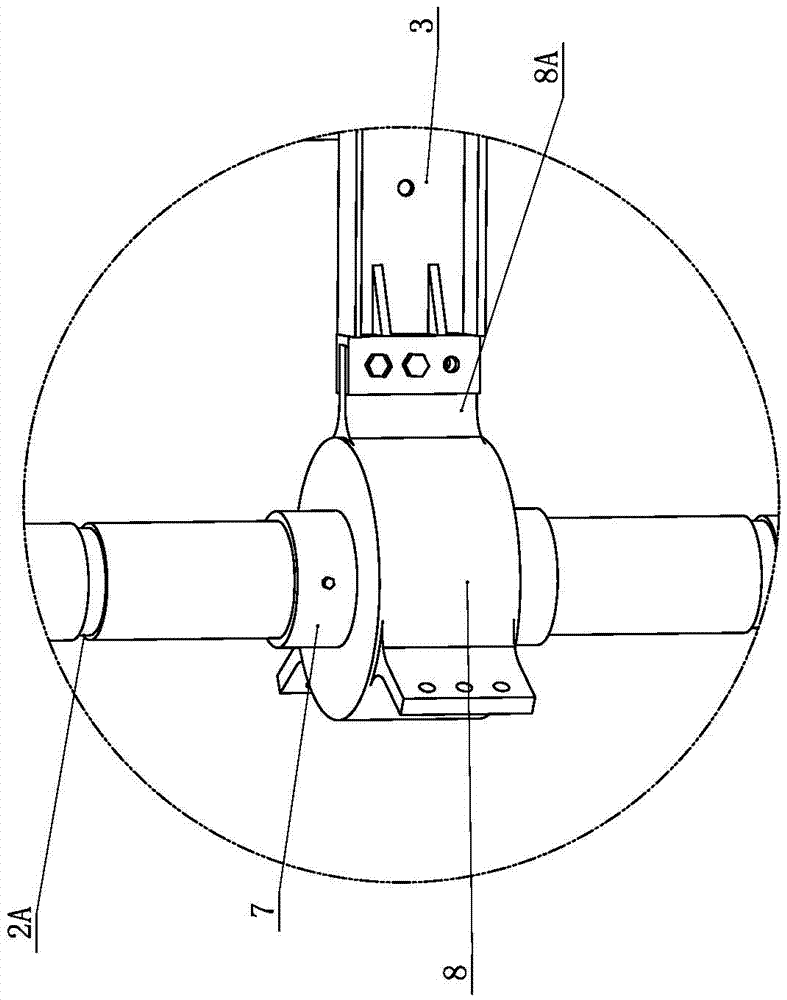

[0024] Such as figure 2 — Figure 4 Shown is the rapid molding tooling for large disc castings of the present invention, including a horizontally supported balance beam 1 connected above the sand box, the middle of the balance beam 1 is fixedly connected to a central shaft 2, and the central shaft 2 is rotatably connected with two horizontal horizontal beams The end of the arm 3 and the cross arm 3 is fixedly connected with a sand scraper. The shape of the scraping surface of the sand scraper matches the shape of the inner or outer contour of the cavity; the connecting end of the cross arm 3 and the central shaft 2 is connected by rotation The sleeve 7 is connected with the bearing sleeve 8, the sleeve 7 is fixedly connected with the central shaft 2, and the outer circumference of the bearing sleeve 8 is fixedly connected with the cross arm 3 through the connecting lug 8A.

[0025] To facilitate precise adjustment of the installation size of the sand scraper, a number of clamping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com