A Continuous Steel Pipe Cutting Processing Control System

A control system, cutting processing technology, applied in the direction of metal processing equipment, metal processing machinery parts, pipe cutting device, etc., can solve the problem of not meeting the production needs well, the efficiency and quality are not very ideal, the heating effect of the air conditioning unit is attenuated, etc. problem, to achieve high production efficiency and good cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

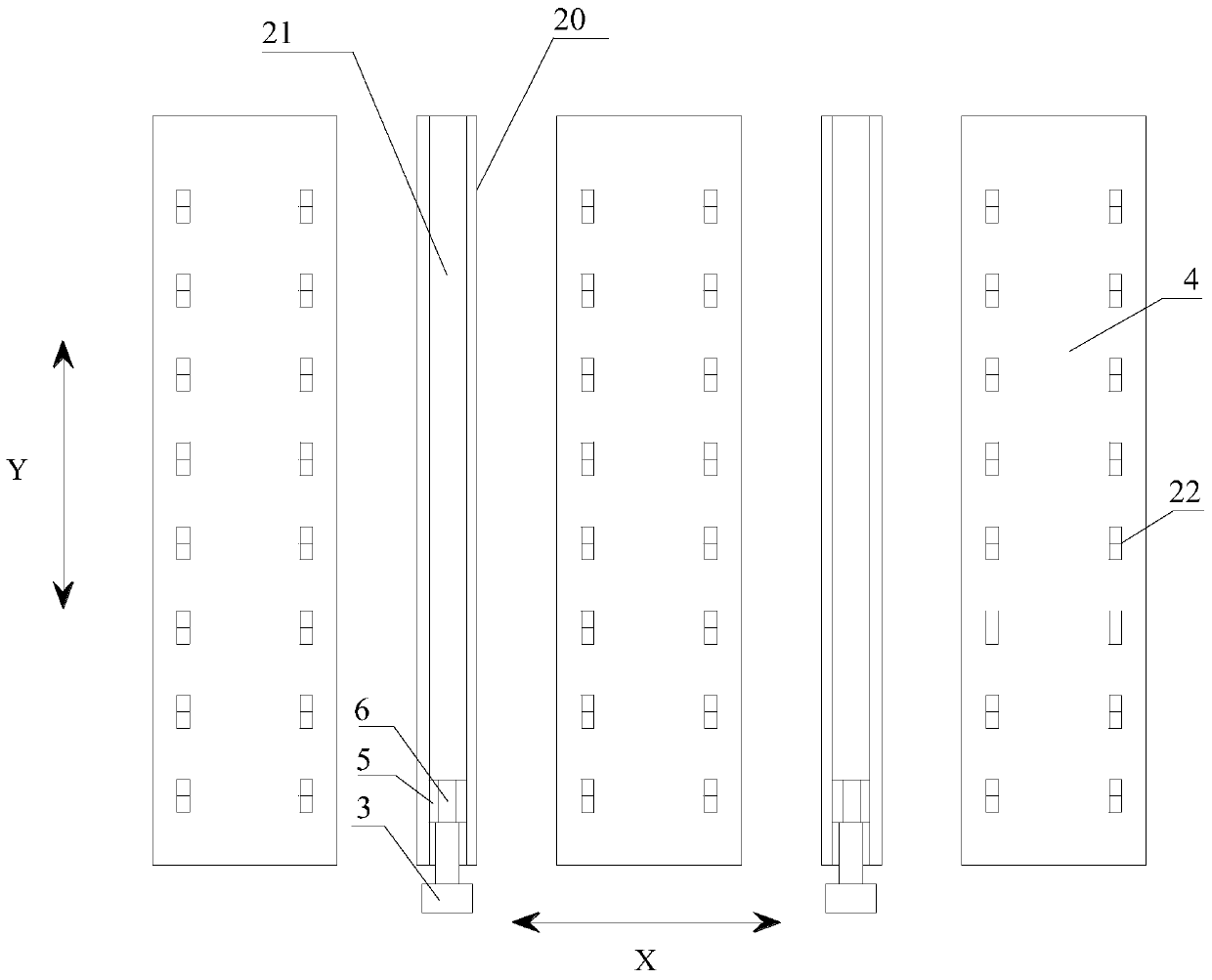

[0023] refer to figure 1 , figure 2 , image 3 , the present invention proposes a continuous steel pipe cutting processing control system, including a clamping mechanism for clamping a steel pipe 1, a cutting mechanism for cutting a steel pipe 1, a mounting frame, a control mechanism, a first driving mechanism 3, a second driving mechanism Mechanism 2 and the third drive mechanism, the control mechanism is connected with the first drive mechanism 3, the second drive mechanism 2, and the third drive mechanism, wherein:

[0024] The mounting frame includes a base 16, a column 17 installed on the base 16 and a second work frame 19 installed on the column 17. The column 17 is provided with a second chute 18 along the Z direction, and the second driving mechanism 2 is installed on the second working frame. Rack 19.

[0025] The clamping mechanism includes at least two first workbenches 4 arranged along the Y direction for clamping the steel pipe 1, the first workbenches 4 are i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com