Grabbing manipulator of synchronizer assembly detection line

A technology of assembly detection and synchronizer, applied in the direction of manipulator, metal processing, metal processing equipment, etc., can solve the problems such as difficulty in guaranteeing detection and assembly accuracy, inability to meet the requirements of consistent production, low detection and assembly efficiency, etc. The effect of convenient transfer, avoiding manual participation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

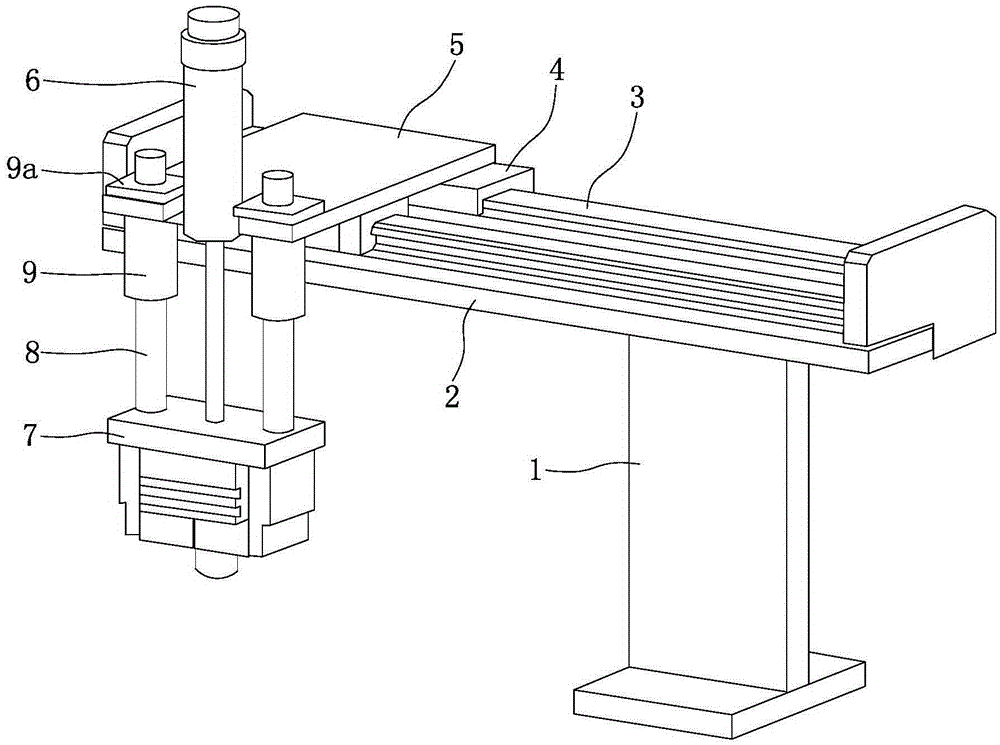

[0013] Such as figure 1 As shown, the frame 1 is preferably an "I" shape or an inverted "T" shape, and a table panel 2 is fixed on the top of the frame 1, and the table panel 2 is rectangular and is located on a horizontal plane. Two mutually parallel linear guide rails 3 are installed on the top surface of the table panel 2, the linear guide rails 3 extend along the length direction of the table panel 2, each linear guide rail 3 is provided with a rodless cylinder 4, and the rodless cylinder 4 is connected to the corresponding Linear guide 3 slide fit. Positioning plate 5 is set above two rodless cylinders 4, and this positioning plate 5 is rectangular, and positioning plate 5 is parallel with table top 2, and the bottom surface of positioning plate 5 is fixed with the cylinder block of two rodless cylinders 4, makes The two rodless cylinders 4 jointly sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com