Cooling control device and method for injection mold

An injection mold and cooling control technology, applied in the field of injection molds, can solve the problems of low mold temperature reliability, lack of control of water temperature in and out of the circulating water circuit, and influence on the judgment of mold cooling uniformity, etc., to achieve simple structure, small warping deformation, The effect of reducing scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

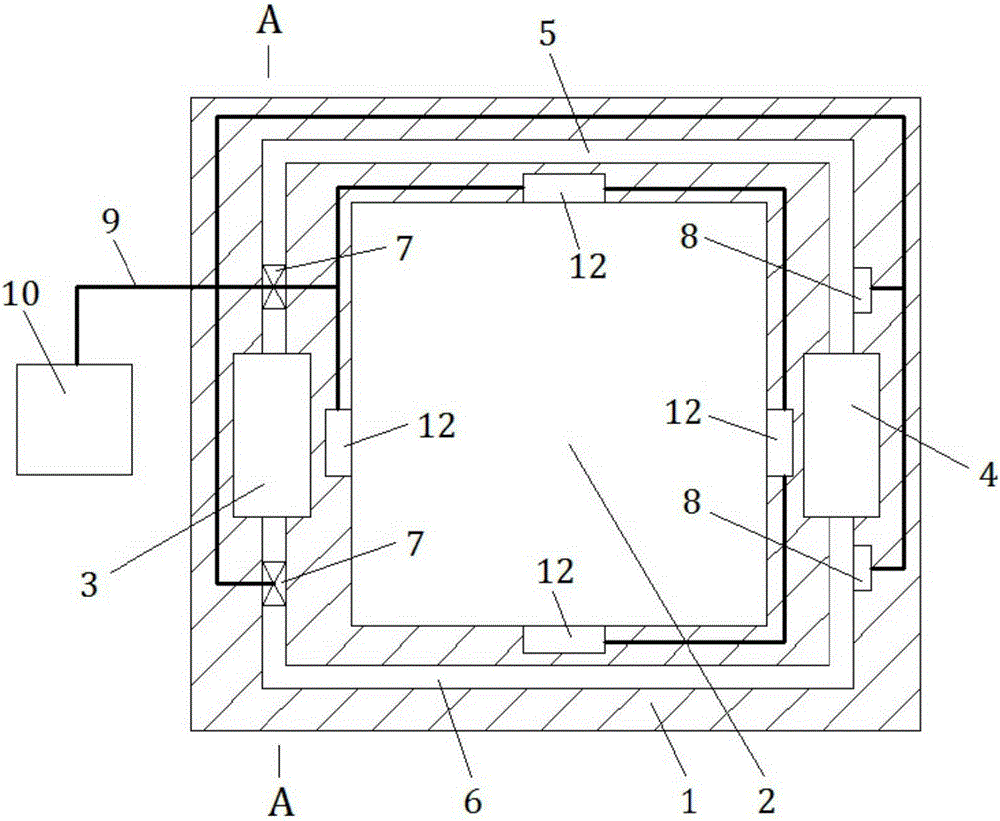

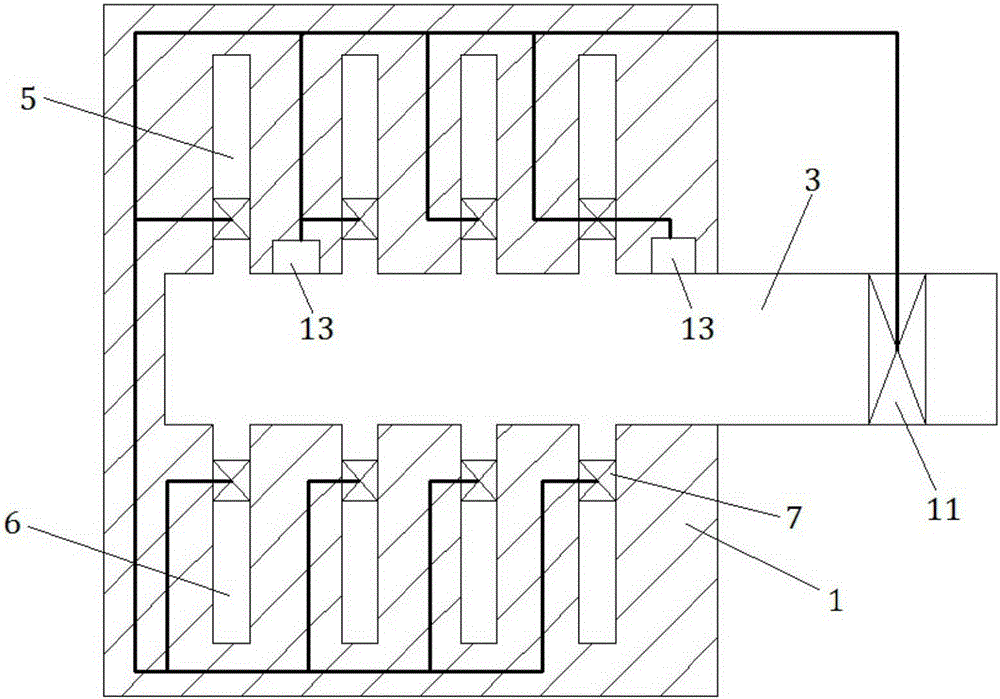

[0030] Such as figure 1 As shown, this embodiment includes: a template 1, a wiring harness 9, a controller 10, a water inlet pipe 3 arranged in the template 1 and forming a circuit, an upper cooling channel 5, an outlet pipe 4 and a lower cooling channel 6, wherein: the upper The water inlet of the cooling channel 5 and the water inlet of the lower cooling channel 6 are respectively connected to the water inlet pipe 3, and the water outlet of the upper cooling channel 5 and the water outlet of the lower cooling channel 6 are respectively connected to the water outlet pipe 4; the controller 10 The wire harness 9 is respectively connected to the water inlet end, the water outlet end of the water inlet pipe 3 and the inner surface of the template 1 .

[0031] The template 1 is provided with a core 2 inside.

[0032] The inner surface of the template 1 is uniformly provided with a surface temperature sensor 12 , and the surface temperature sensor 12 is connected to the controller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com