A pattern structure suitable for driving wheel mixed road surface

A pattern structure, driving wheel technology, applied in the direction of tire tread/tread pattern, tire parts, transportation and packaging, etc., can solve the problems of accelerating tire wear, reducing tire service life, increasing heat generation, etc., to achieve good driving. performance, improve heat dissipation, reduce rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

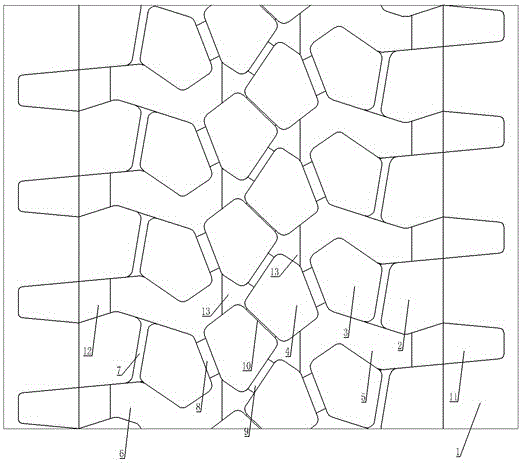

[0014] Such as figure 1 The pattern structure shown is suitable for the mixed road surface of the driving wheel, including the first pattern block 2 arranged along the tire circumferential direction near the tire shoulder, and the second pattern block 3 arranged along the tire circumferential direction close to the first pattern block. A third pattern block 4 is arranged between the two second pattern blocks, and the third pattern block is also arranged along the tire circumferential direction, and a first sipe 10 is arranged on the third pattern block, and the first sipe 10 is embedded with a The steel sheet, the third pattern block 4 is a continuous pattern block, and the first sipe 10 in the middle of the block helps the tire dissipate heat. The first pattern block and the second pattern block are connected by the first pattern block connecting rib 7, and the second pattern block and the third pattern block are connected by the second pattern block connecting rib 8, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com