Elastic reverse triggering mechanism

A trigger mechanism and reverse technology, applied in conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problem of huge data processing capacity, difficult to meet the requirements of the service life of micro switches, and general products without suitable structure and other problems to achieve the effect of reducing damage, increasing service life and improving utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

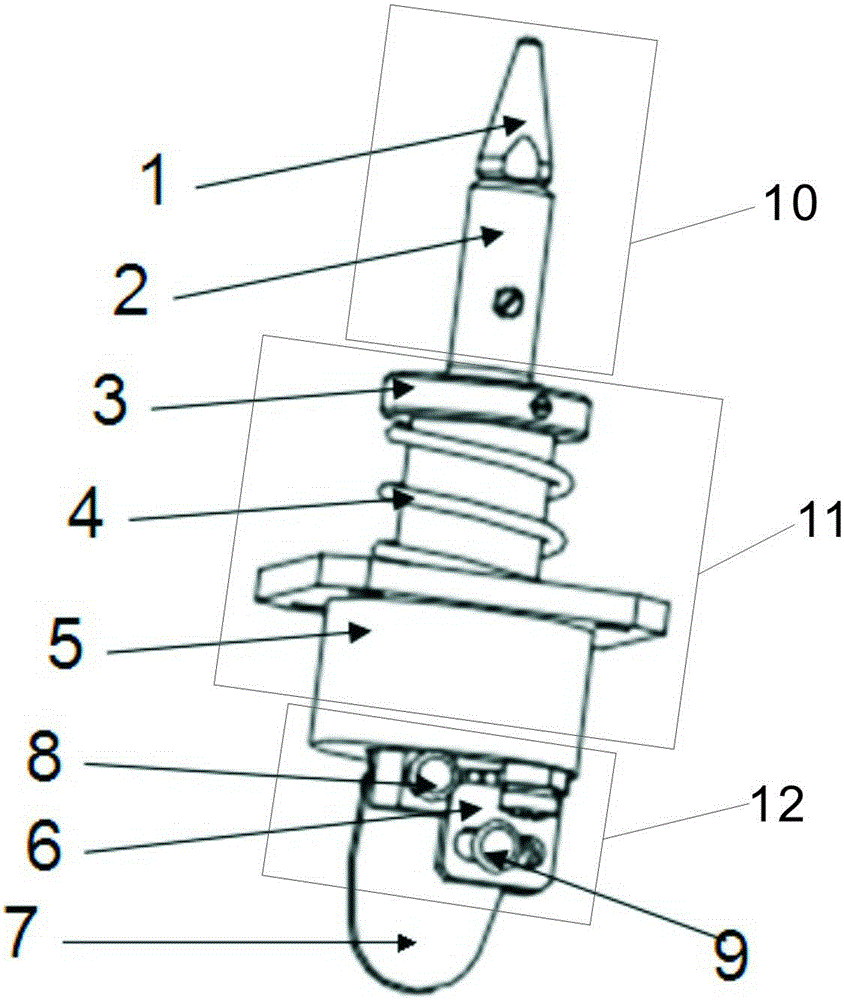

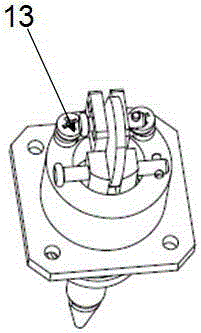

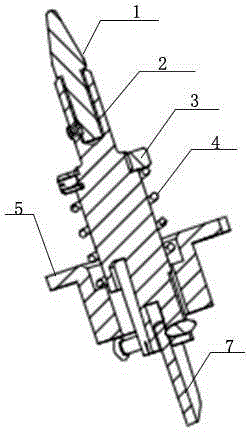

[0022] As shown in the figure, an elastic reverse trigger mechanism is provided with a probe assembly, an elastic telescopic assembly and a reverse assembly. The probe assembly is composed of a probe head 1 and a probe rod 2. The probe head and the external contact end are in the shape of a truncated cone, and the top surface is an arc surface, so that the probe can accurately enter the tearing area of the conveyor belt during detection. One end of the probe head 1 has an external thread, and the probe rod 2 is provided with an internal thread, and the two are connected by threads to form a probe assembly; and the material of the probe head is wear-resistant nylon, which not only protects the conveyor belt in contact with it, but also is not easy to wear. And it can be easily disassembled when worn to a certain extent. In this way, an elastic reverse trigger mechanism can be used reliably and safely for many times, which improves the utilization rate of the product and reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com