smt produces airflow delivery device with tin-based spherical solder powder

A kind of air conveying, spherical technology, applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., can solve the problems of changing tissue properties, temperature rise of centrifugal atomized powder, dust escape, etc., to avoid pollution and reduce dust. Pollution, good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

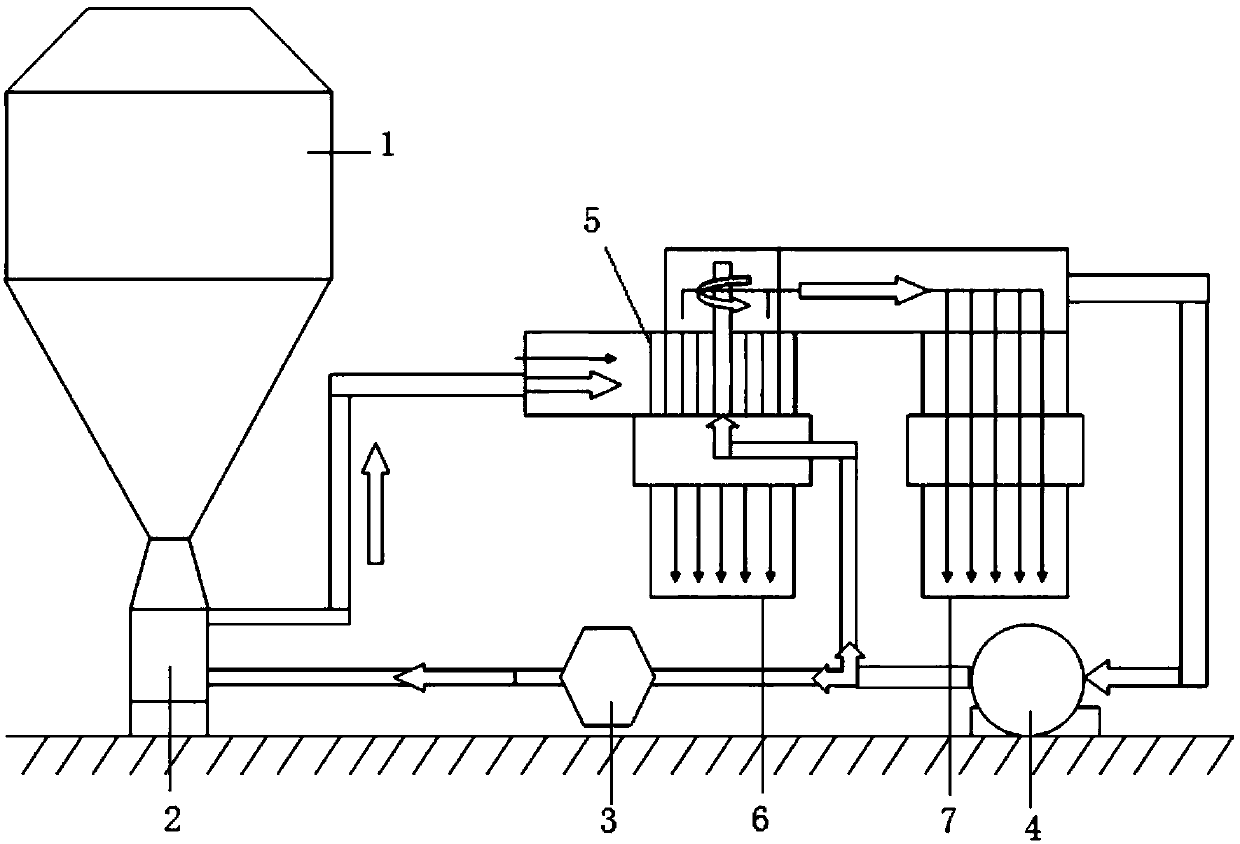

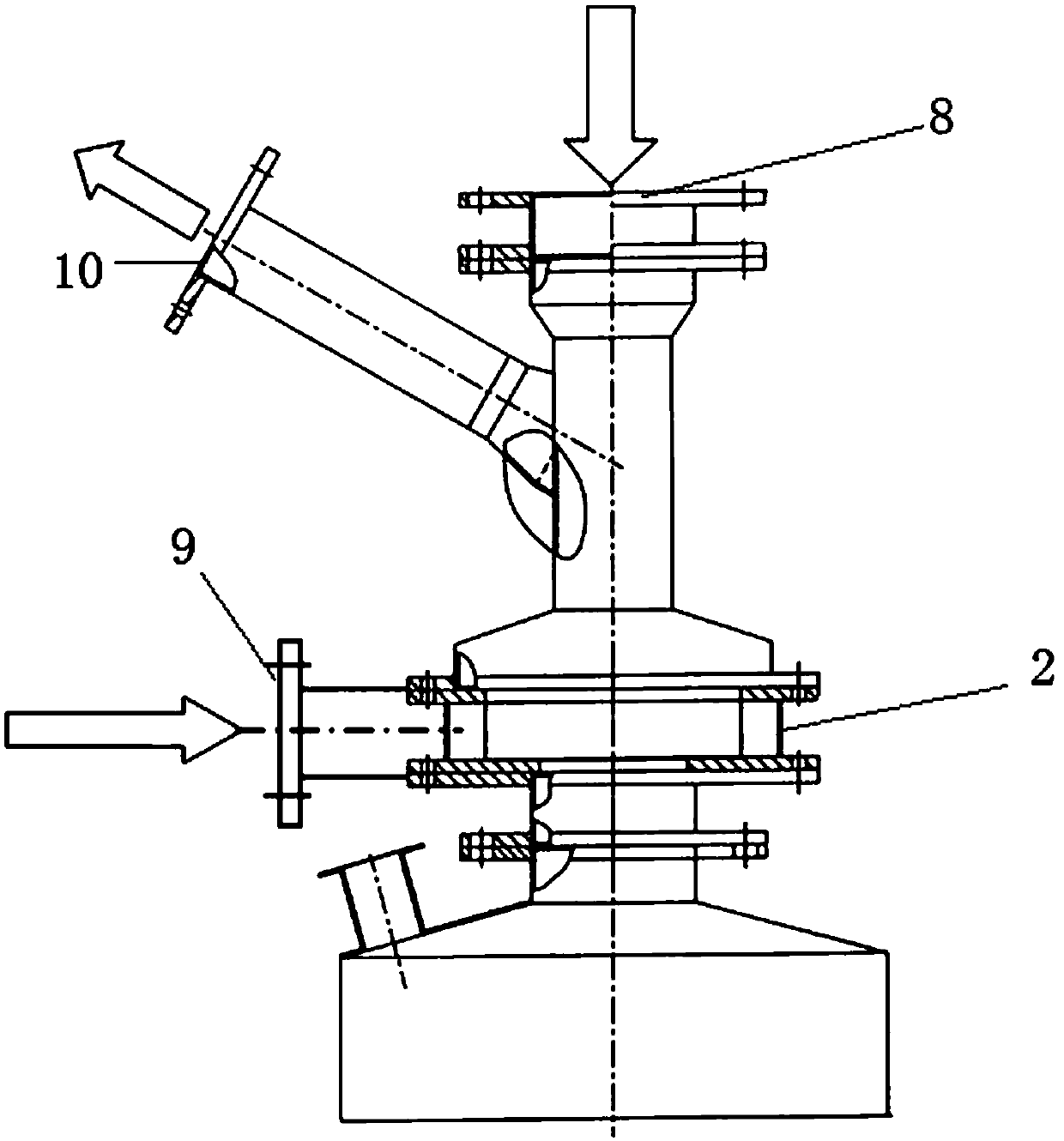

[0014] A kind of SMT uses tin-based spherical solder powder to produce airflow conveying device, the structure is as follows Figure 1-2 As shown, it includes the centrifugal atomization chamber 1, the lower part of the centrifugal atomization chamber 1 is provided with a cyclone conveyor 2, the cyclone conveyor 2 is connected with the lower part of the centrifugal atomization chamber 1 through the feed port 8 provided at the upper end, and the side of the cyclone conveyor 2 is arranged There is an air inlet 9, and the upper part of the cyclone conveyor 2 is also provided with a material outlet 10; the air outlet end of the centrifugal blower 4 is divided into two paths, and one path is connected with the air inlet 9 of the cooler 3 and the cyclone conveyor 2 successively through the pipeline, The other way communicates with the upper part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com