A kind of preparation method of glucosinolate and its metabolite benzyl isothiocyanate

A technology of benzyl isothiocyanate and glucosinolate, applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problem of low yield, environmental pollution, extraction and separation of benzyl isothiocyanate No problems such as reports have been reported, achieving the effects of low extraction temperature, avoidance of thermal damage, and safe extraction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

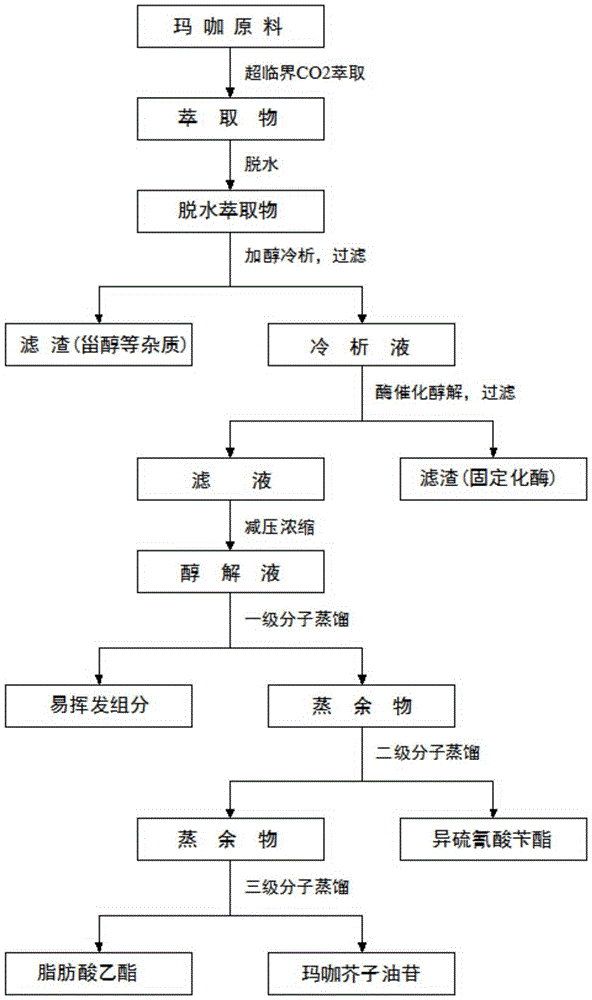

[0038] A preparation method of glucosinolate and its metabolite benzyl isothiocyanate, the steps and conditions thereof are as follows:

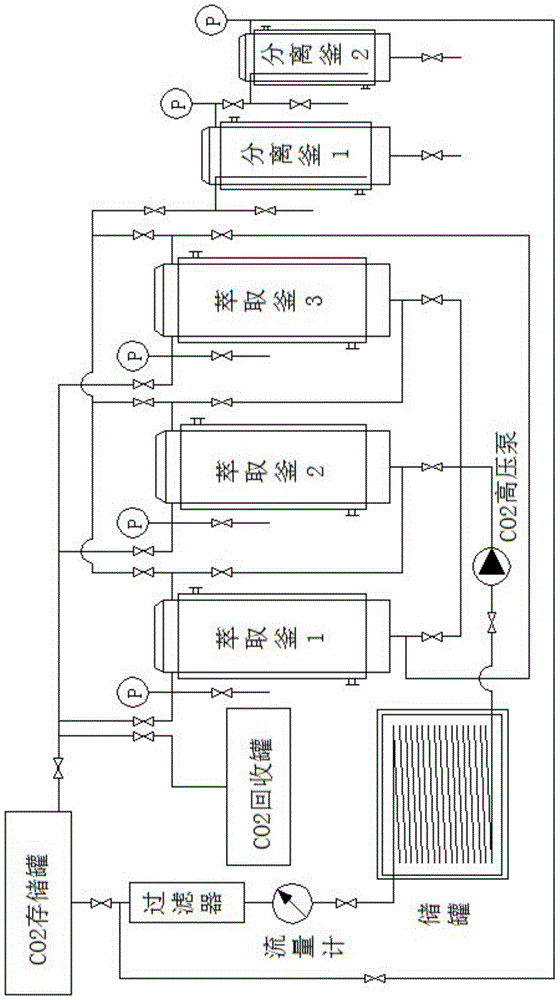

[0039] Step 1: Tertiary Supercritical CO 2 extraction

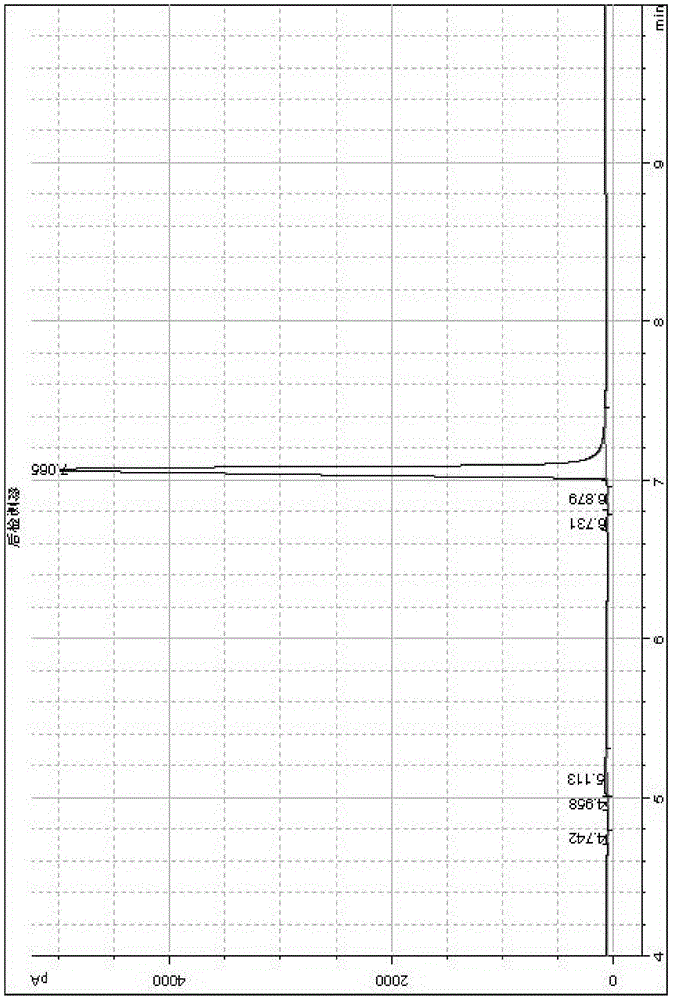

[0040] 10.00kg of maca (containing 3.54% benzyl isothiocyanate and 4.05% glucosinolate) was inactivated by microwaves, crushed to 100 mesh, and three-stage series supercritical CO 2 extraction, such as figure 2 As shown, three series-connected extraction kettle 1, extraction kettle 2, and extraction kettle 3 are connected to two series-connected separation kettle 1, separation kettle 2, CO 2 The flow rate is 300L / h, the extraction pressure is 16.0MPa, the extraction temperature is 65.0°C, the primary separation pressure is 6.5Mpa, the primary separation temperature is 50.0°C, the secondary separation pressure is 4.5Mpa, and the secondary separation temperature is 50.0°C. After extracting for 100.0min, release the extract from separation tanks 1 and 2; use three-stage series supercri...

Embodiment 2

[0050] A preparation method of glucosinolate and its metabolite benzyl isothiocyanate, except for the following differences, other steps and process conditions thereof are the same as in Example 1:

[0051] (1) Step 1: CO 2 The flow rate is 240L / h, the extraction pressure is 20.0MPa, the extraction temperature is 55.0°C, the extraction time is 75.0min, the primary separation pressure is 7.5Mpa, the primary separation temperature is 40.0°C, the secondary separation pressure is 5.0Mpa, and the secondary separation pressure is 5.0Mpa. The separation temperature was 40.0°C, and 1.19 kg of dehydrated extract was obtained.

[0052] (2) Step 2: The quality of adding absolute ethanol is 1.05kg, stirring once every 30.0min with intermittent stirring, 3.0min each time, the cooling rate of intermittent stirring is 3.0°C / h, the static cooling analysis temperature is 0.0°C, and the static cooling The analysis time is 12.0h.

[0053] (3) Step 3: 60.0 g of immobilized enzyme was added, the r...

Embodiment 3

[0056] A preparation method of glucosinolate and its metabolite benzyl isothiocyanate, except for the following differences, other steps and process conditions thereof are the same as in Example 1:

[0057] (1) Step 1: CO 2 The flow rate is 180L / h, the extraction pressure is 24.0MPa, the extraction temperature is 46.0°C, the extraction time is 50.0min, the primary separation pressure is 8.5Mpa, the primary separation temperature is 30.0°C, the secondary separation pressure is 6.0Mpa, and the secondary separation pressure is 6.0Mpa. The separation temperature was 30.0°C, and 1.25 kg of dehydrated extract was obtained.

[0058] (2) Step 2: The quality of adding absolute ethanol is 1.20kg, stirring once every 60.0min with intermittent stirring, 5.0min each time, the cooling rate of intermittent stirring is 2.0°C / h, the static cooling analysis temperature is 5.0°C, and the static cooling The analysis time is 18.0h.

[0059] (3) Step 3: 90.0 g of immobilized enzyme was added, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com