Loading and unloading method capable of preventing automatic container terminal AGV and quay crane from waiting for each other and quay crane

A container and wharf technology, which is applied in the field of port automation container wharf, can solve problems that plague the determination of automated wharf scheme construction, and achieve the effect of reducing the number of configurations, reducing input costs, and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

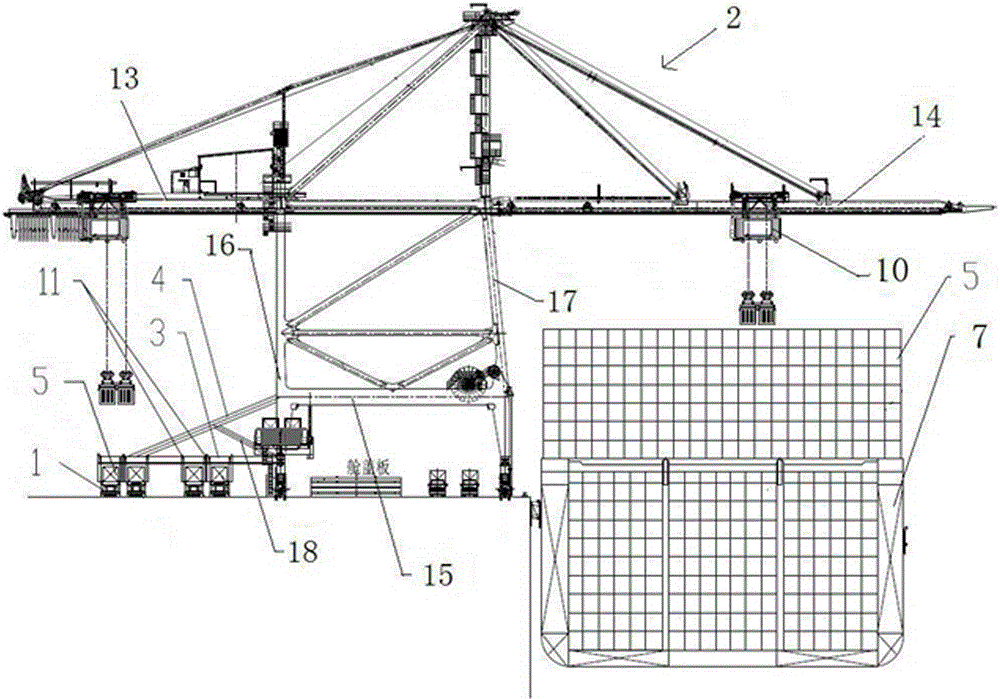

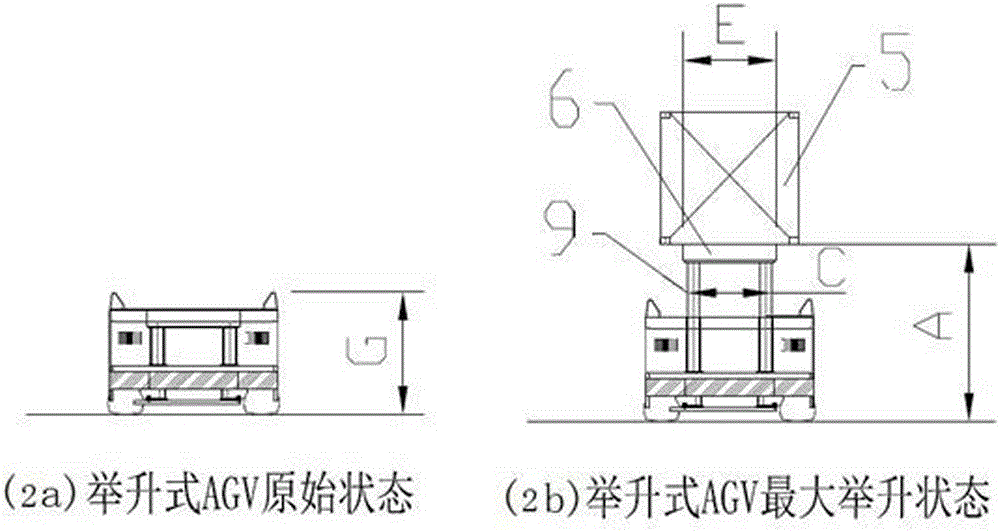

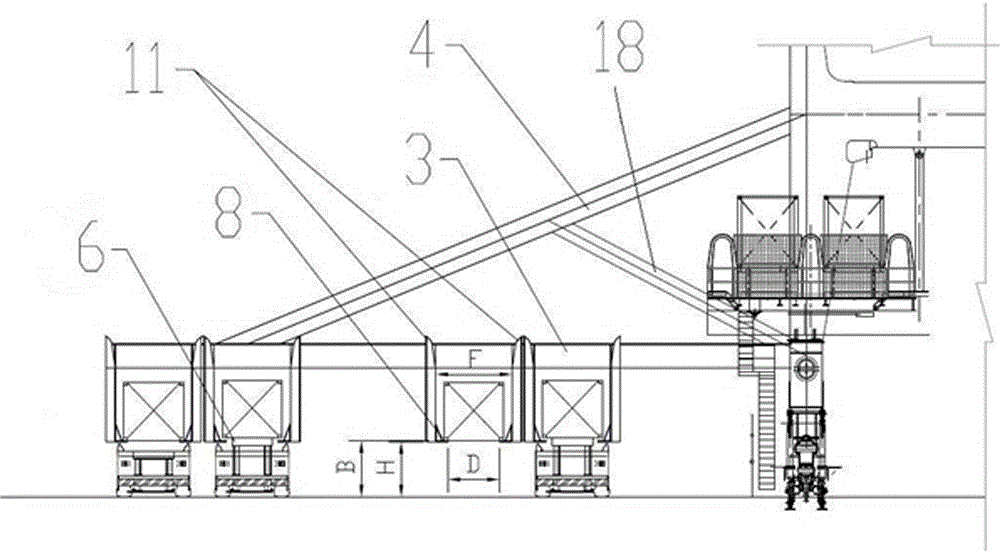

[0060] Such as figure 1 As shown in -6, a quay crane that solves the mutual equivalence between the AGV and the quay crane in the automated container terminal, its main structure 2 includes a land side door 16, a sea side door frame 17, and a girder erected on the land side door frame 16 and the sea side door frame 17 14. The land-side door frame 16 and the sea-side door frame 17 are connected by the connecting crossbeam 15 of the sea-land side door frame. The girder 14 is provided with the running track 13 of the quay bridge trolley, and the rear of the land-side door frame column 12 of the land-side door frame 16 is provided with a container box suspension Group 3, the quay crane trolley 10 runs on the quay crane trolley running track 13, and is used for the vertical and horizontal transportation of the container 5 from the container ship 7 to the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com