Composite toughening modifier and its preparation method and application

A toughening modifier and toughening modification technology are applied in the field of polymer materials to achieve the effects of improving processing flow properties, elastic recovery and surface activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

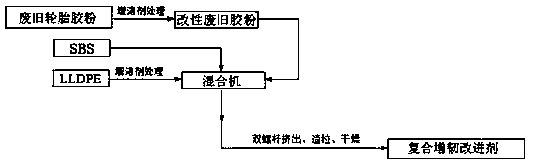

[0063] Embodiment 1 Composite toughening modifier

[0064] The present invention prepares the composite toughening modifier by mixing and melt-extruding each component of the following parts by weight:

[0065] 15 parts of waste tire rubber powder;

[0066] Thermoplastic styrene-butadiene rubber (SBS) 45 parts;

[0067] 40 parts of polyethylene resin;

[0068] Solubilizer 1 part.

[0069] The waste tire rubber powder is obtained by pulverizing waste tires for vehicles, and can be obtained through regular commercial purchase. The particle size of the waste tire rubber powder is 100-200 mesh. The thermoplastic elastomer is selected from SBS, the polyethylene resin is selected from low-density polyethylene (LLDPE) resin, and the solubilizer is selected from K10H naphthenic oil (EPDM paraffin oil or white oil specially used for elastomers can also be used).

[0070] The preparation method of the composite toughening improver is as follows:

[0071] S21. Put the waste tire ru...

Embodiment 2

[0077] The present invention prepares the composite toughening modifier by mixing and melt-extruding each component of the following parts by weight:

[0078] 20 parts of waste tire rubber powder;

[0079] Thermoplastic styrene-butadiene rubber (SBS) 40 parts;

[0080] 40 parts of polyethylene resin;

[0081] Solubilizer 1 part.

[0082]The waste tire rubber powder is obtained by pulverizing waste tires for vehicles, and can be obtained through regular commercial purchase. The particle size of the waste tire rubber powder is 100-200 mesh. The thermoplastic elastomer is selected from SBS, the polyethylene resin is selected from low-density polyethylene (LLDPE) resin, and the solubilizer is EPDM paraffin oil (K10H naphthenic oil or white oil specially used for elastomers can also be used).

[0083] The preparation method of the composite toughening improver is as follows:

[0084] S21. Put the waste tire rubber powder into the mixer, turn on the mixer, spray the solubilizin...

Embodiment 3

[0090] The present invention prepares the composite toughening modifier by mixing and melt-extruding each component of the following parts by weight:

[0091] 30 parts of waste tire rubber powder;

[0092] Thermoplastic styrene-butadiene rubber (SBS) body 30 parts;

[0093] 40 parts of polyethylene resin;

[0094] Solubilizer 1.5 parts.

[0095] The waste tire rubber powder is obtained by pulverizing waste tires for vehicles, and can be obtained through regular commercial purchase. The particle size of the waste tire rubber powder is 100-200 mesh. The polyethylene resin is selected from low-density polyethylene (LLDPE) resin, and the solubilizer is white oil specially used for elastomers (K10H naphthenic oil or EPDM paraffin oil can also be used).

[0096] The preparation method of the composite toughening improver is as follows:

[0097] S21. Put the waste tire rubber powder into the mixer, turn on the mixer, spray the solubilizing agent into the mixer, mix evenly, pour ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com