Transmission mechanism of sewing machine

A transmission mechanism and sewing machine technology, which is applied to sewing machine components, sewing machine control devices, sewing equipment, etc., can solve problems such as complex structures, and achieve the effects of simplifying difficulty, improving noise, and simplifying structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

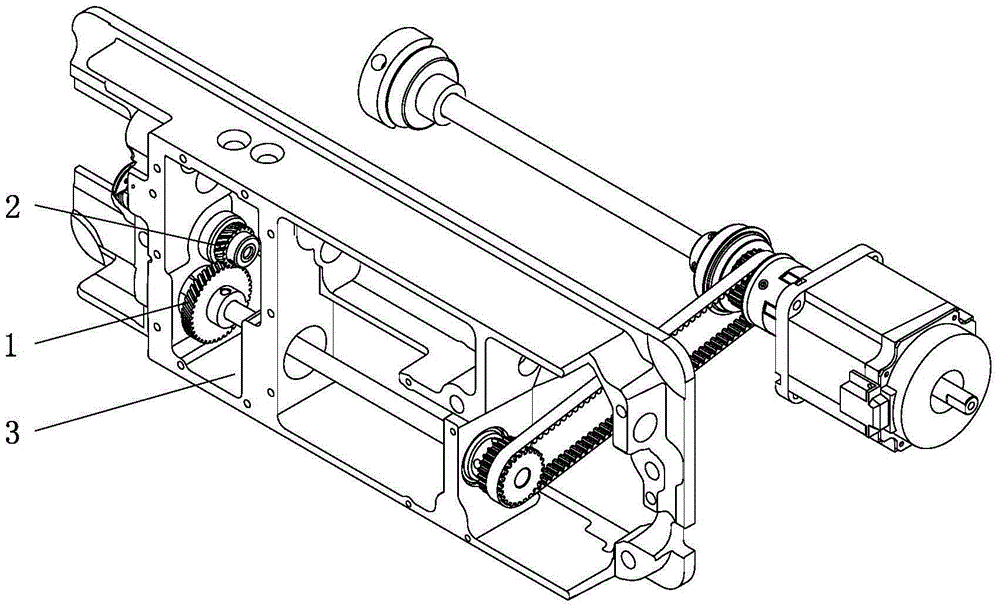

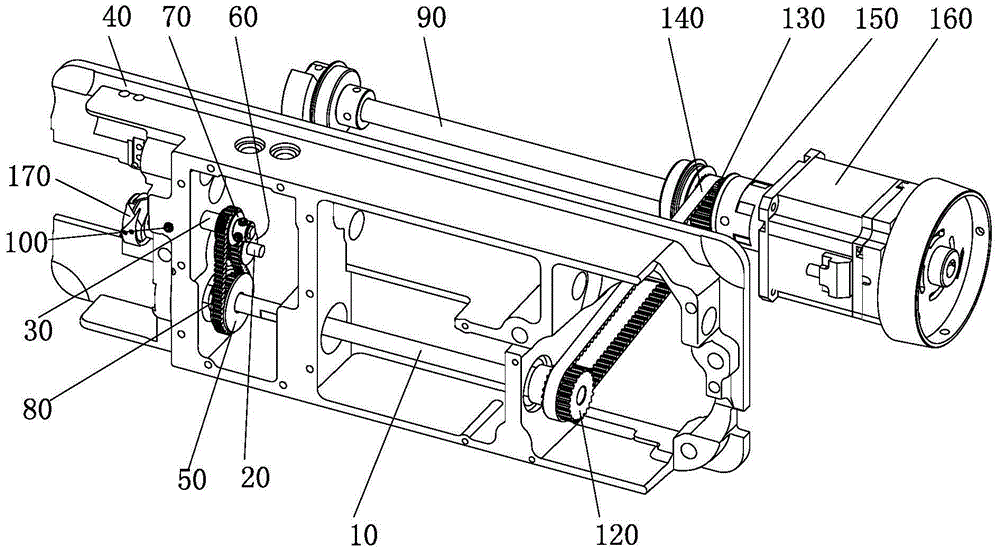

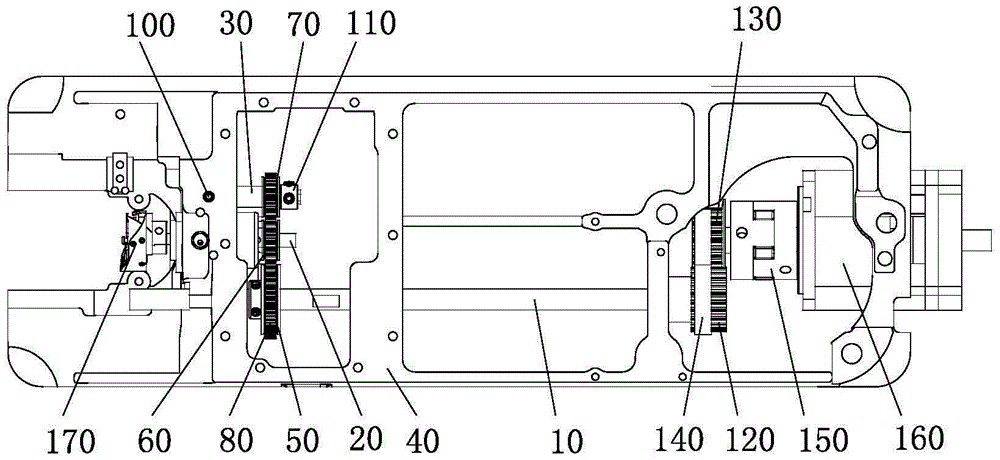

[0020] The present invention will be further described below with specific embodiment, see figure 2 -6:

[0021] The transmission mechanism of the sewing machine includes the epicyclic shaft 10, the lower shaft 20 and the tension wheel adjustment shaft 30. The belt pulley 50, the lower shaft 20 is provided with a lower shaft synchronous pulley 60, the tensioner adjustment shaft 30 is provided with a tensioner 70, and a double-sided tooth synchronous belt is arranged outside the tensioner 70 and the large synchronous pulley 50 80, the tension pulley 60, the large synchronous pulley 50 are connected to the inner teeth of the double-sided tooth synchronous belt 80, and the lower shaft synchronous pulley 60 is connected to the outer teeth of the double-sided tooth synchronous belt 80. The epicyclic shaft 10 passes through The transmission device is connected with the upper shaft 90 and drives the action. The rotary hook 170 of sewing machine is installed on the front end of low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com