Patents

Literature

30results about How to "Change noise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

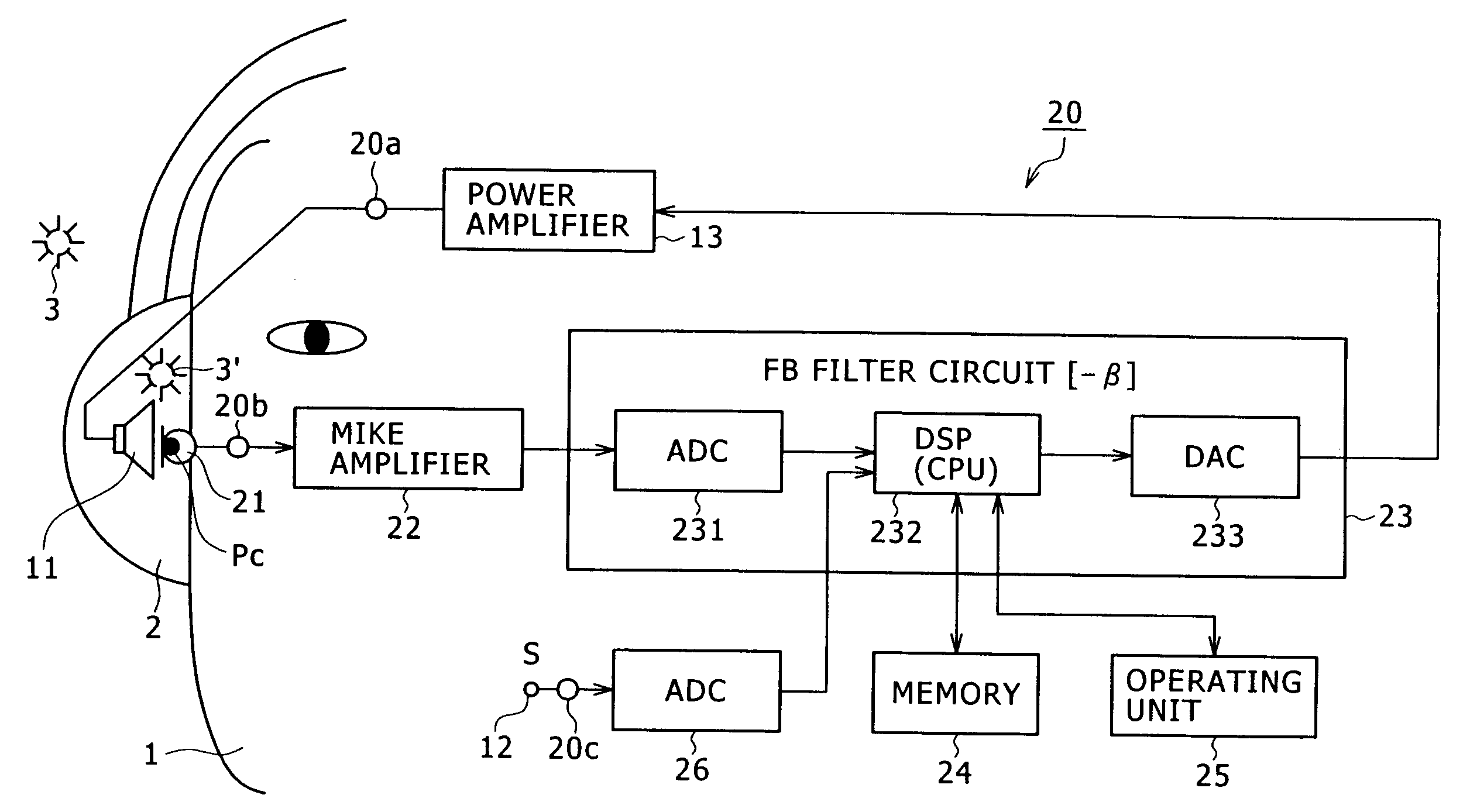

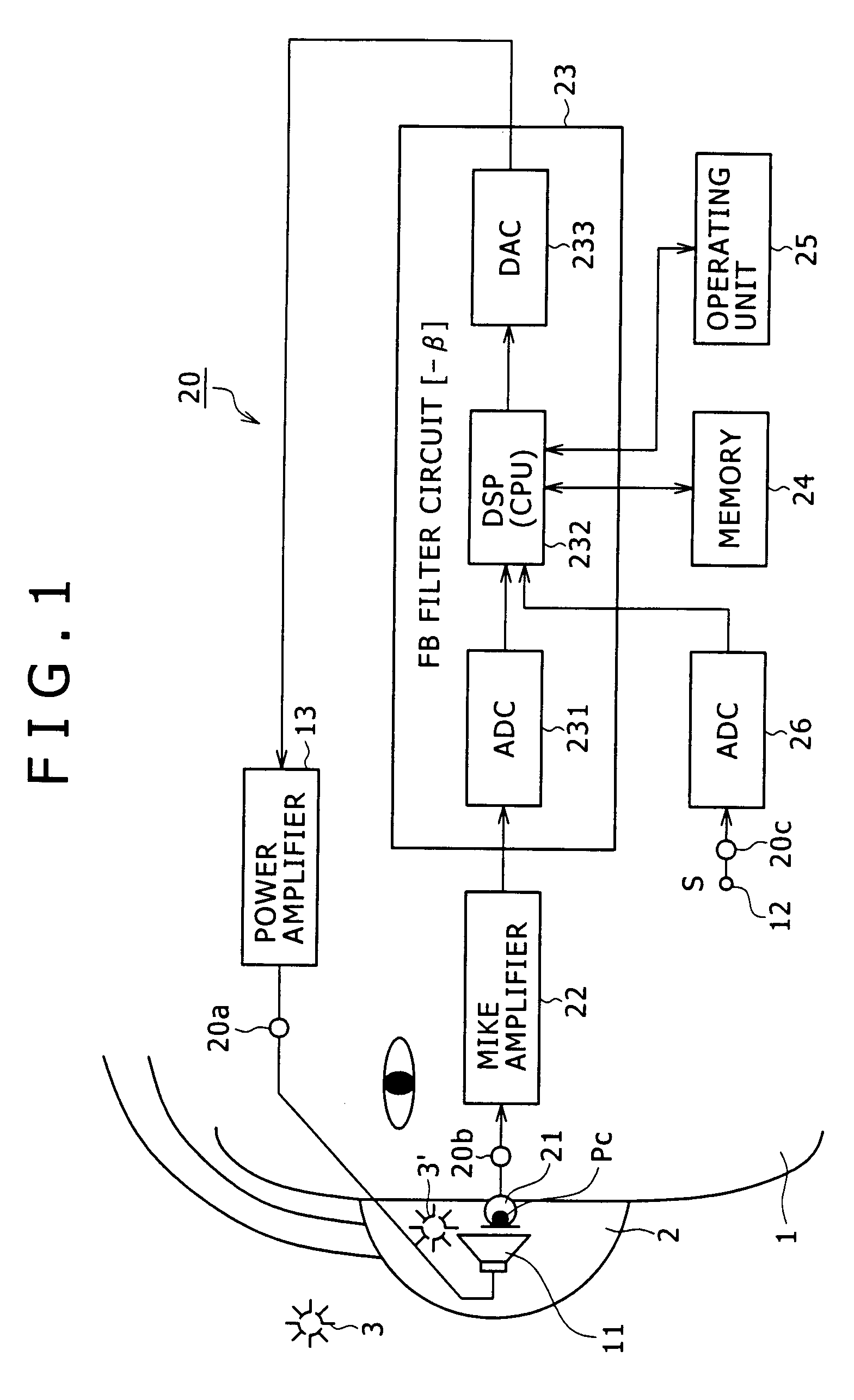

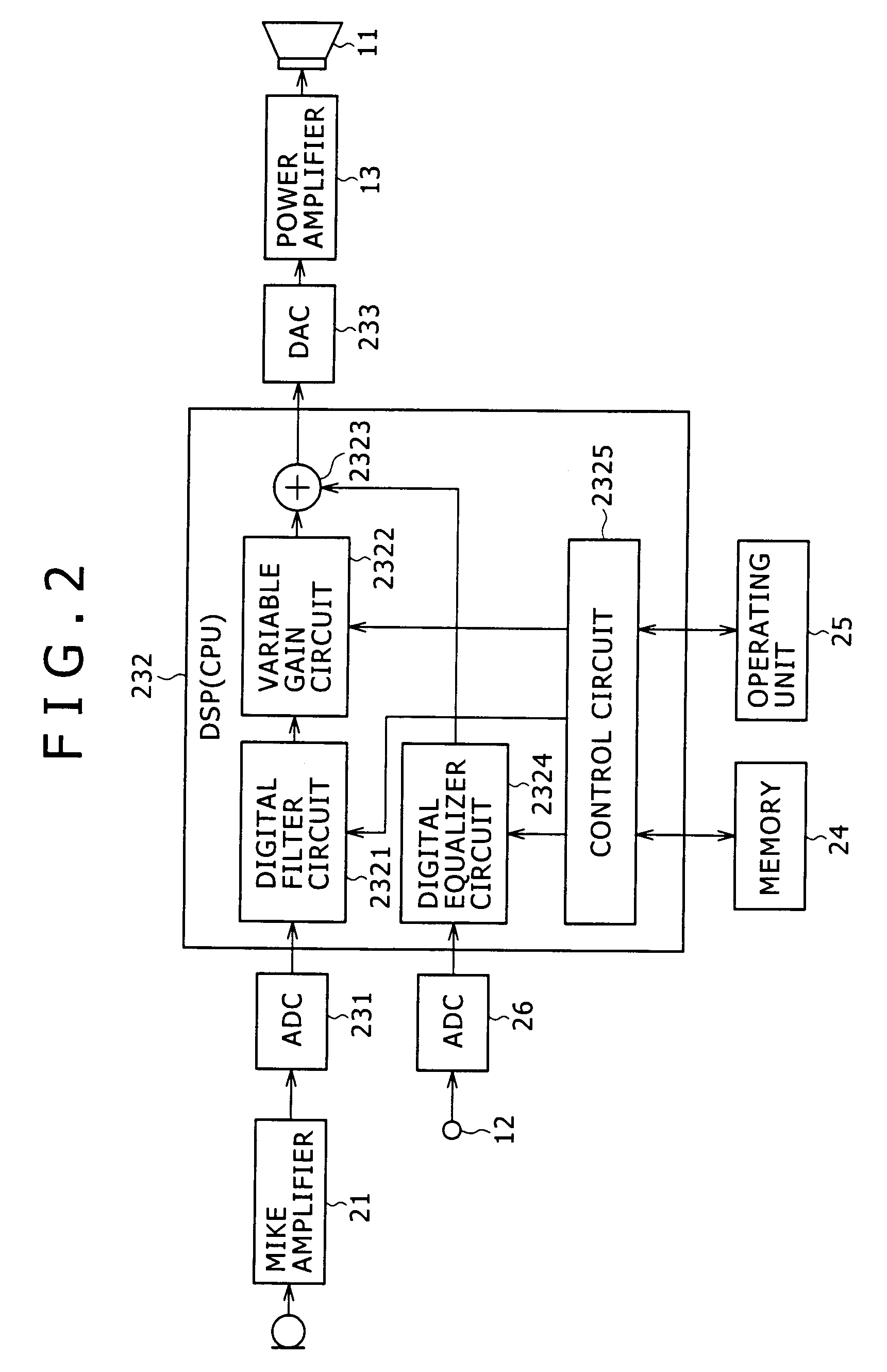

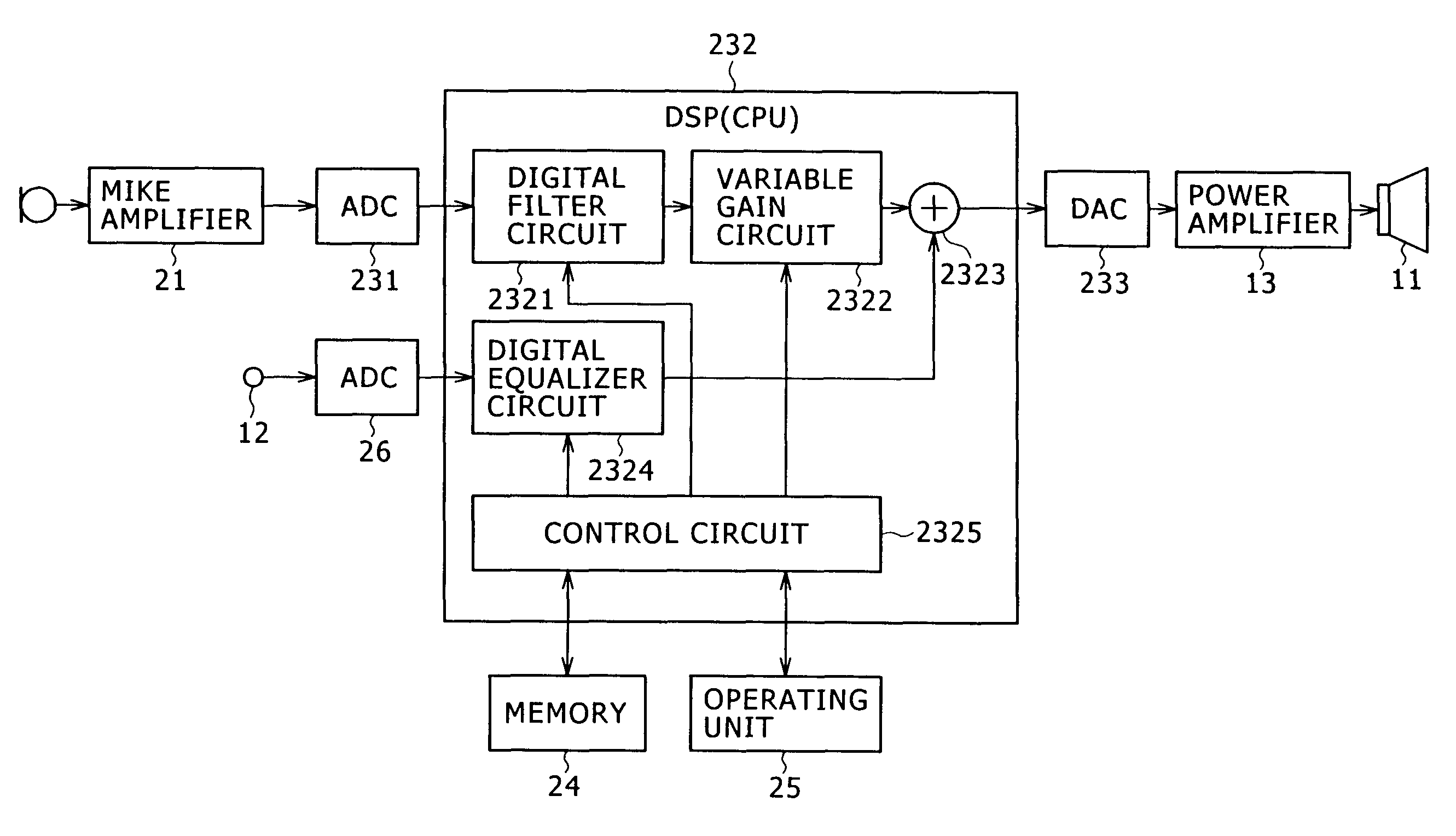

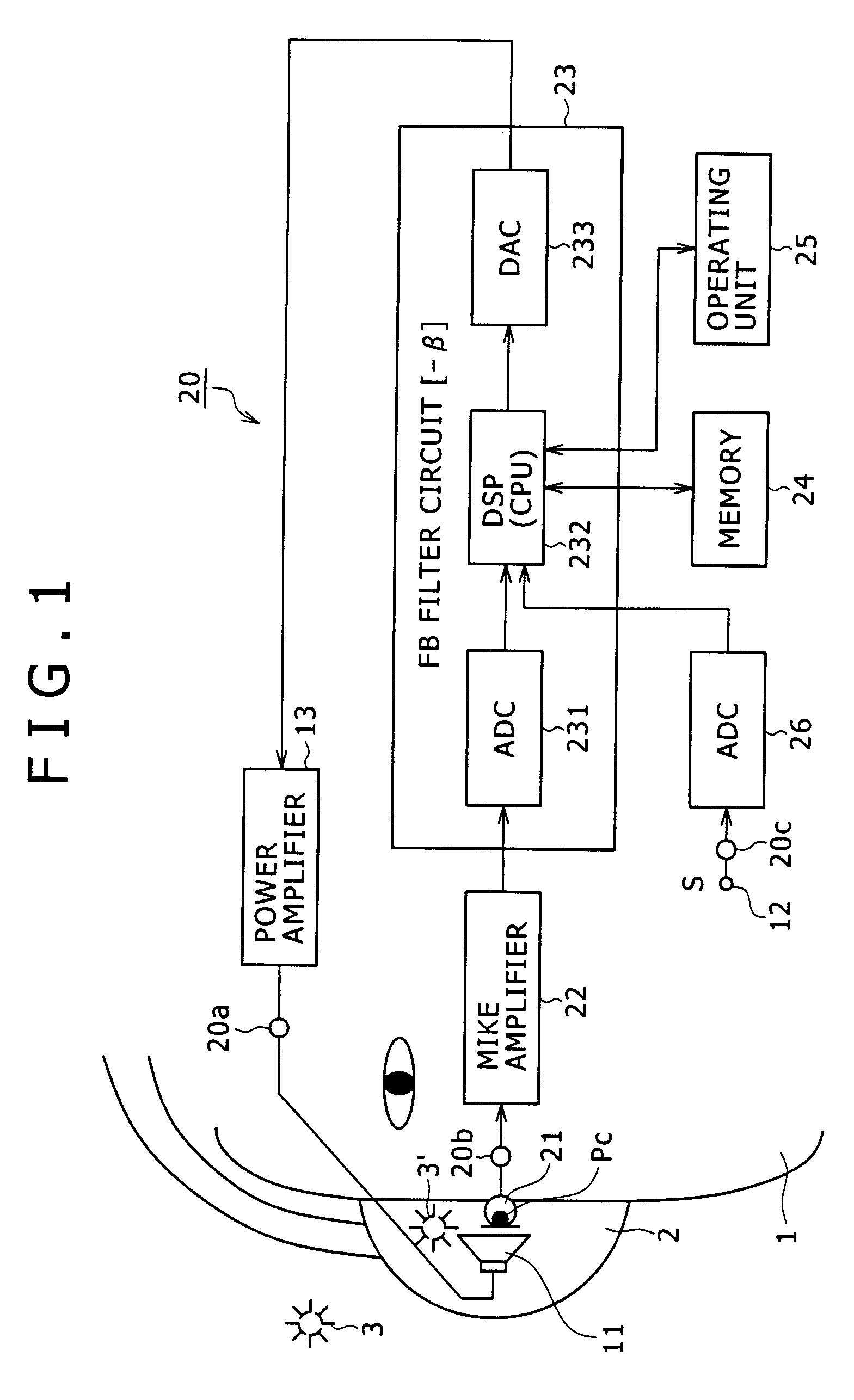

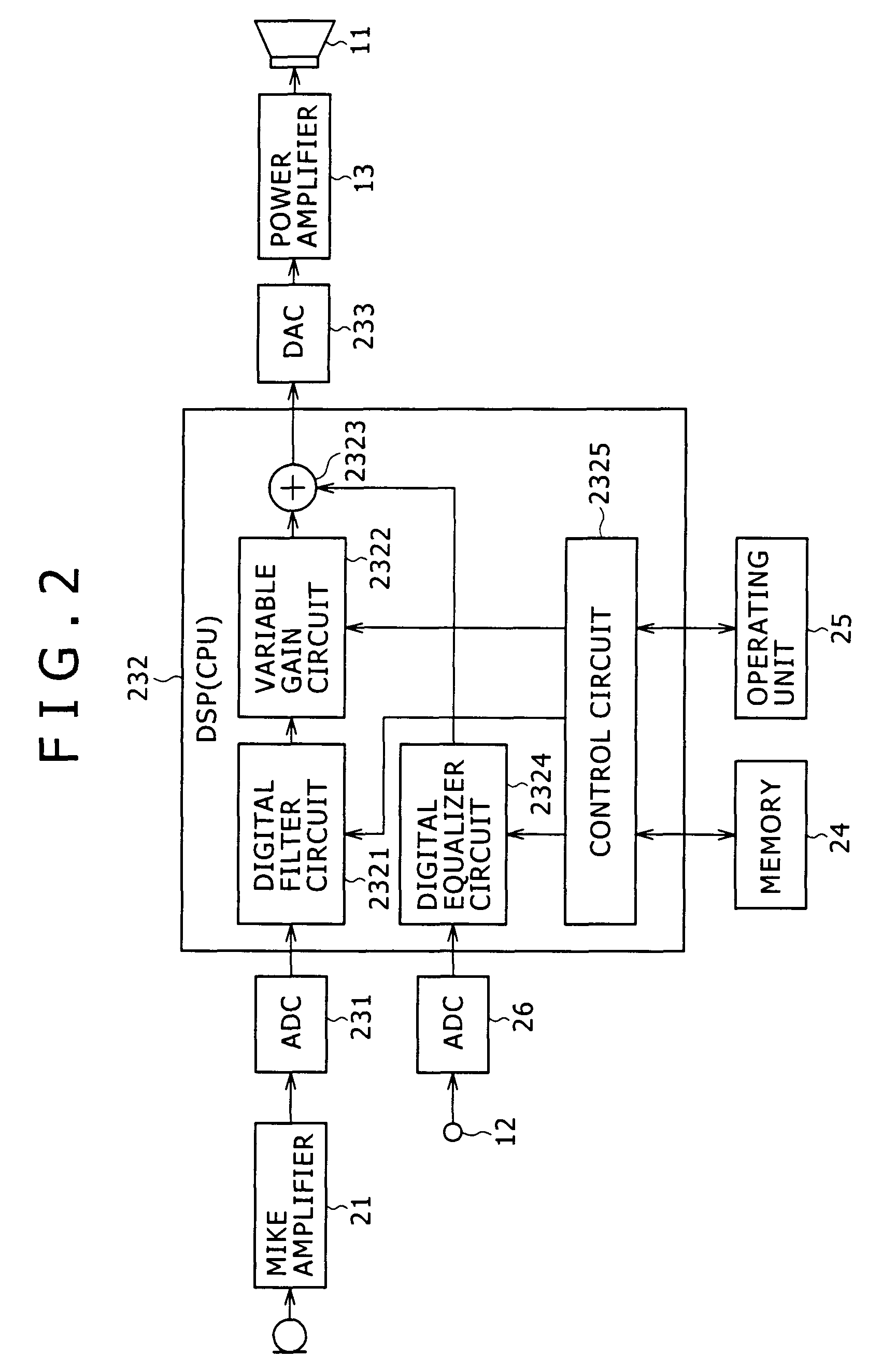

Audio outputting device, audio outputting method, noise reducing device, noise reducing method, program for noise reduction processing, noise reducing audio outputting device, and noise reducing audio outputting method

ActiveUS20080159555A1Easily check effectImprove noise reductionEar treatmentHeadphones for stereophonic communicationOutput deviceNoise reduction

Disclosed herein is an audio outputting device for switching a plurality of processes to perform a process on an audio signal, and acoustically reproducing and outputting the audio signal, the audio outputting device including, a control section for, when changing a process performed on an audio signal from one process to another process, stopping the one process on the audio signal, outputting sound based on the audio signal unprocessed by either of the one process and the other process, and performing the other process on the audio signal after passage of a predetermined period of time.

Owner:SONY CORP

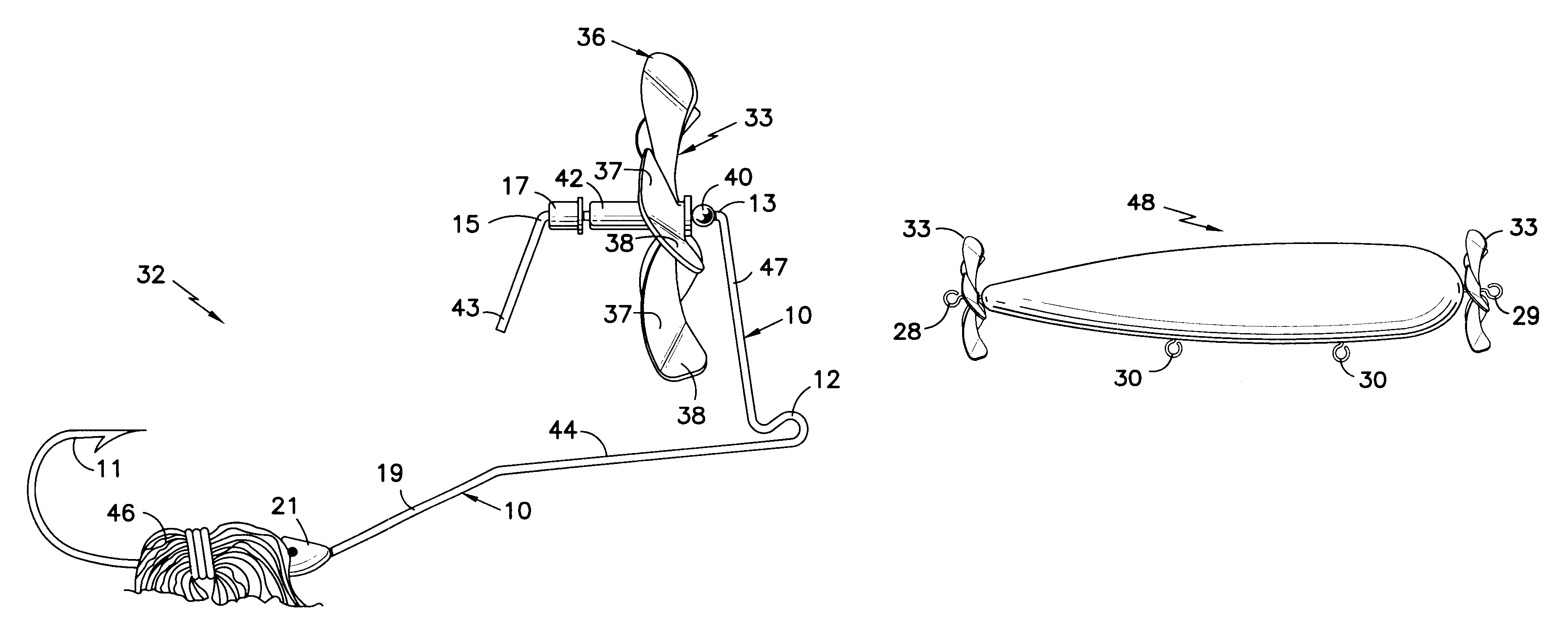

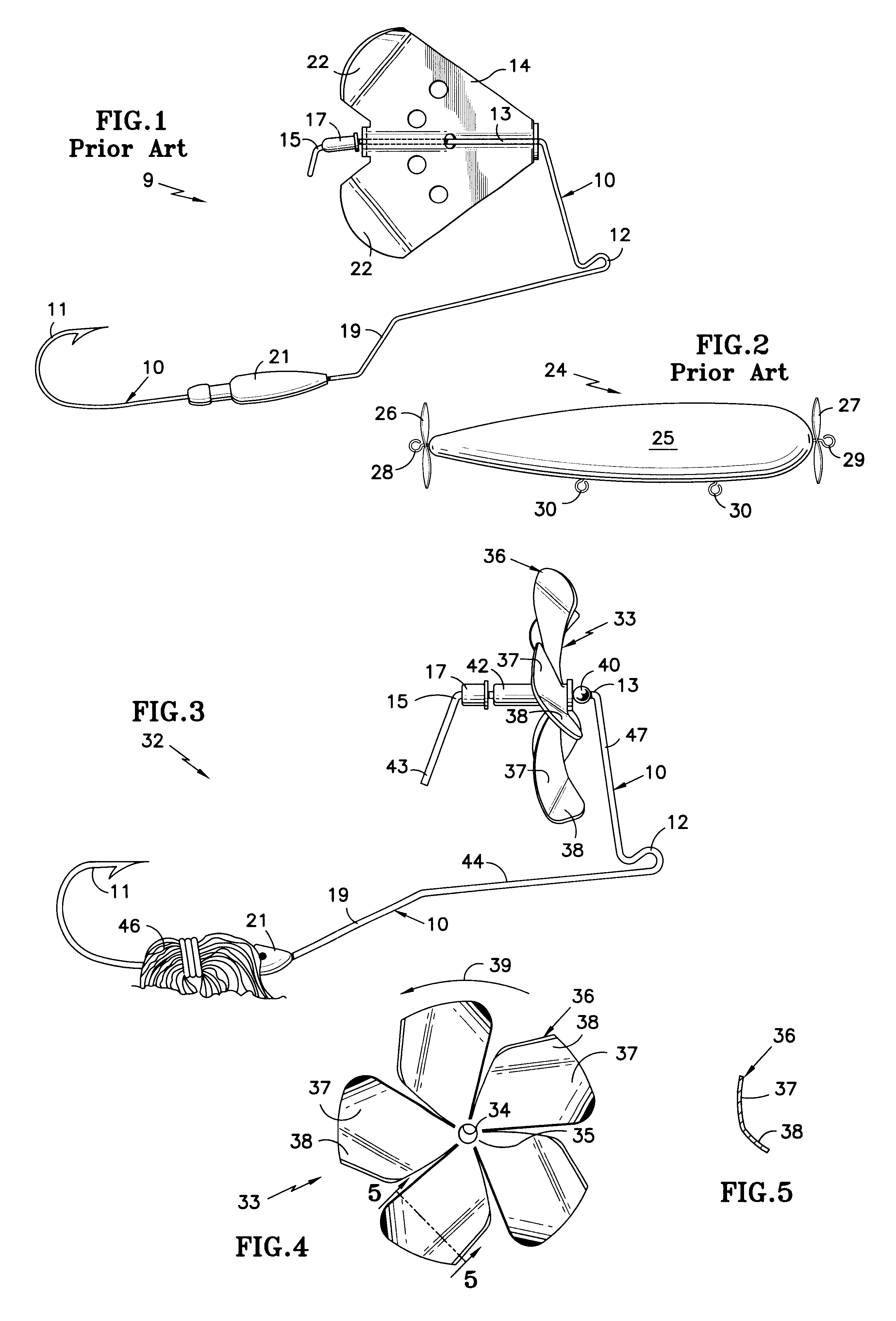

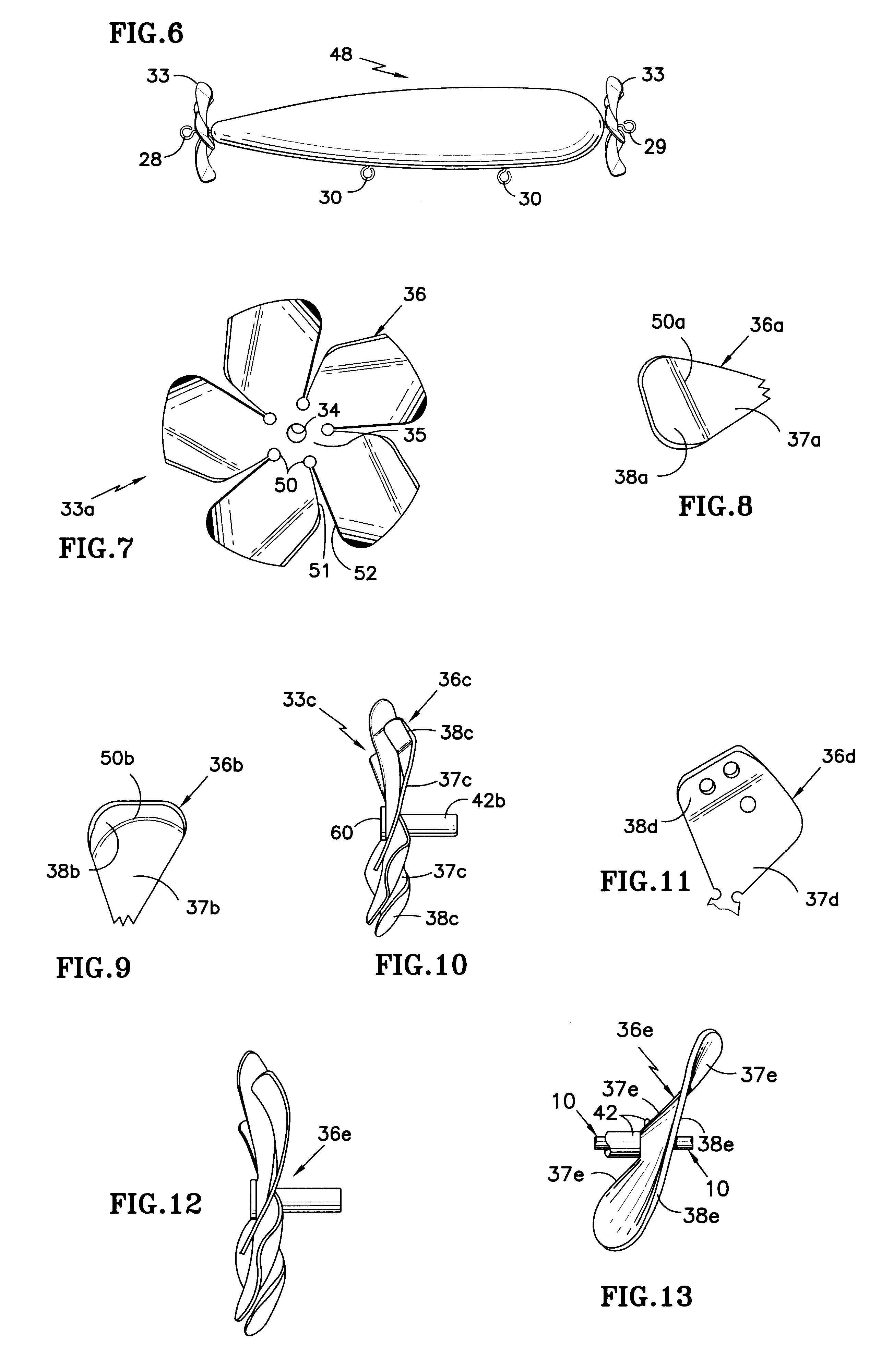

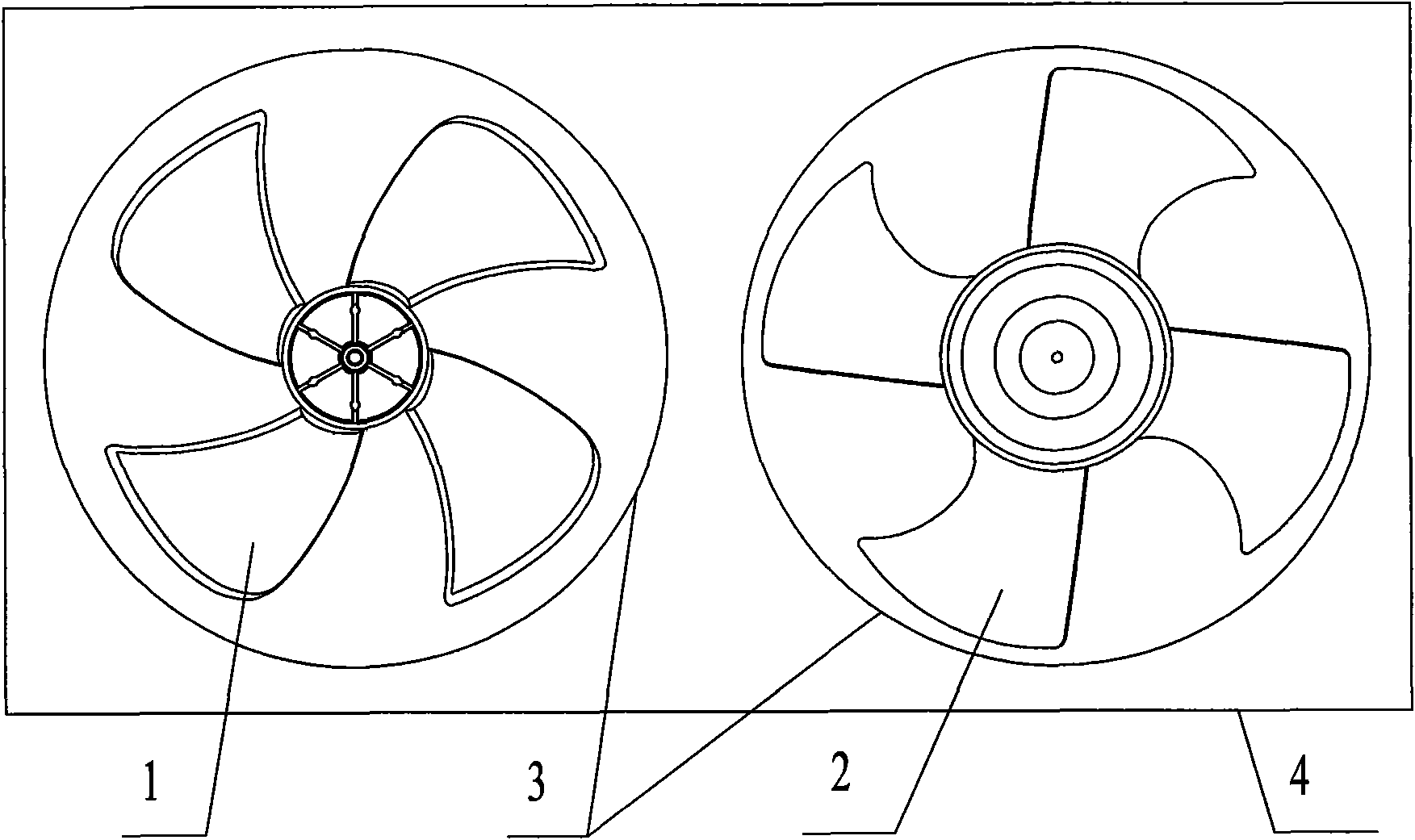

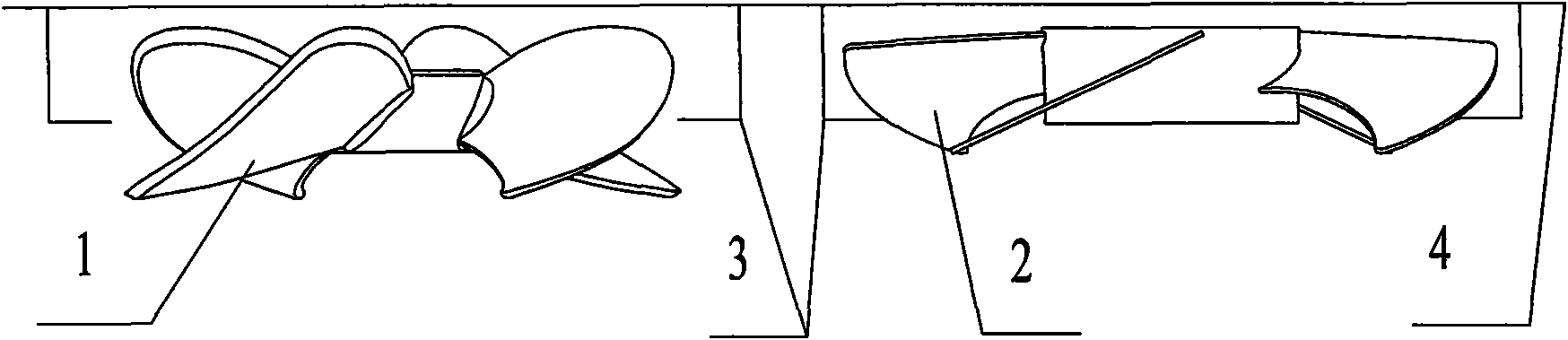

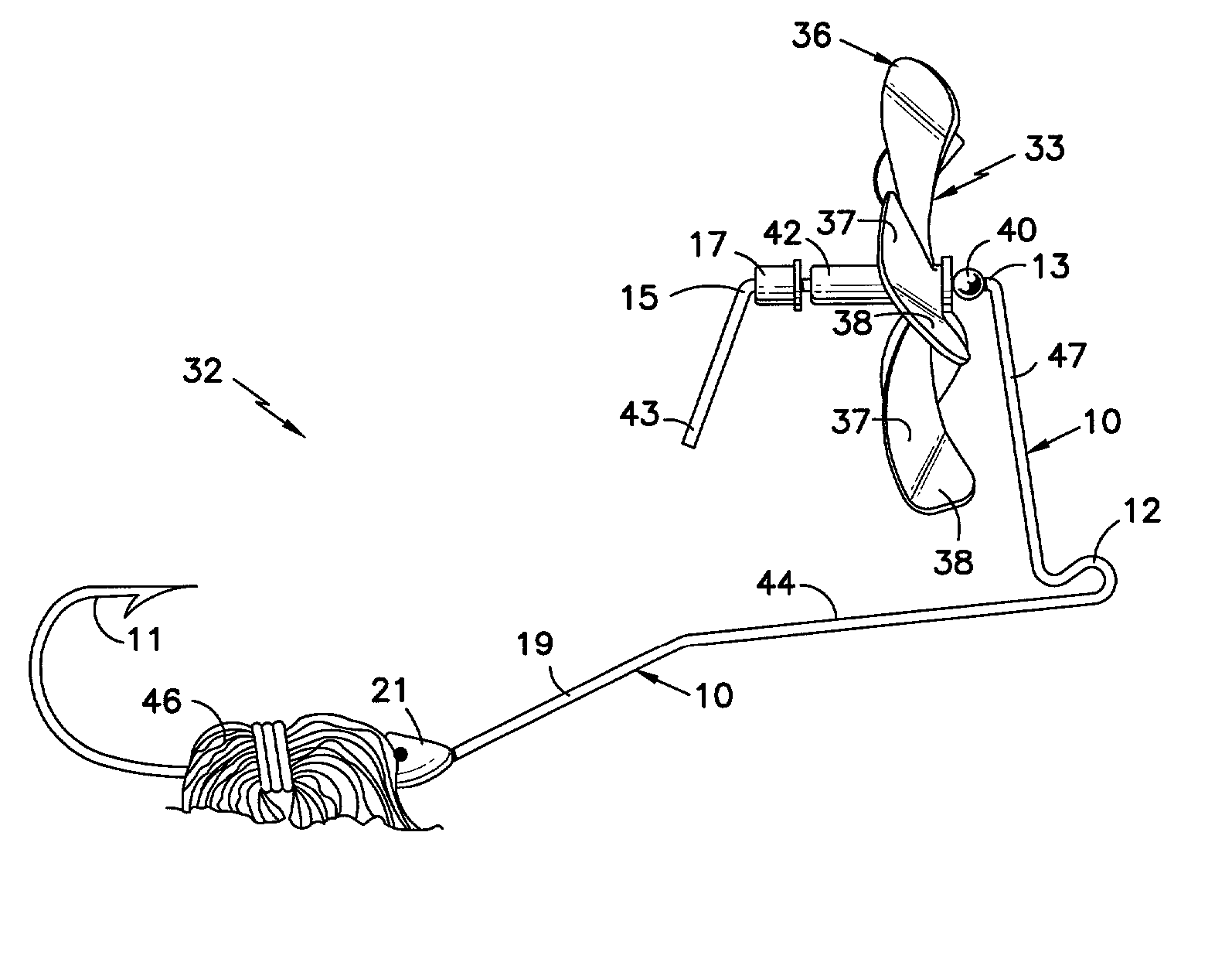

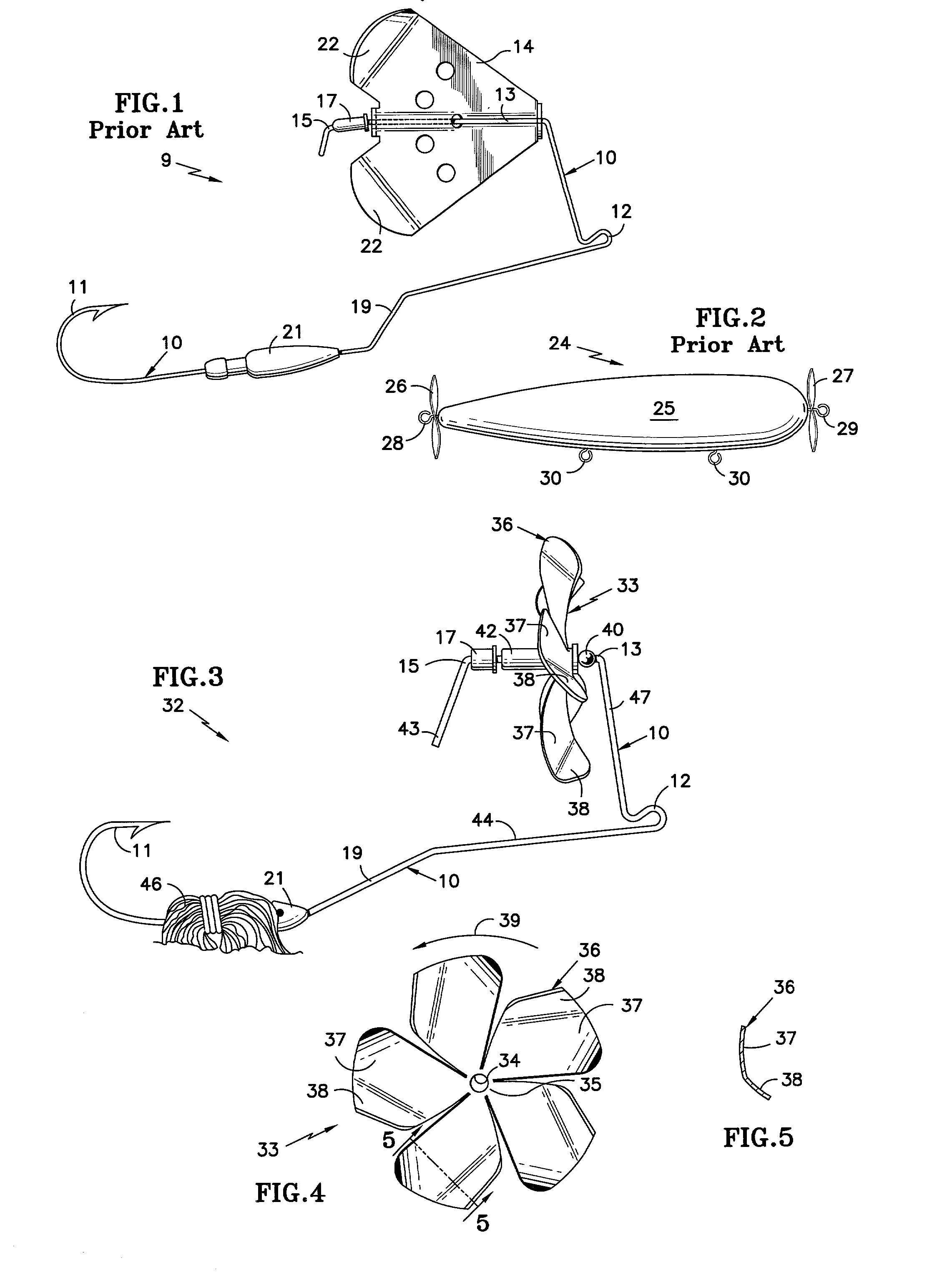

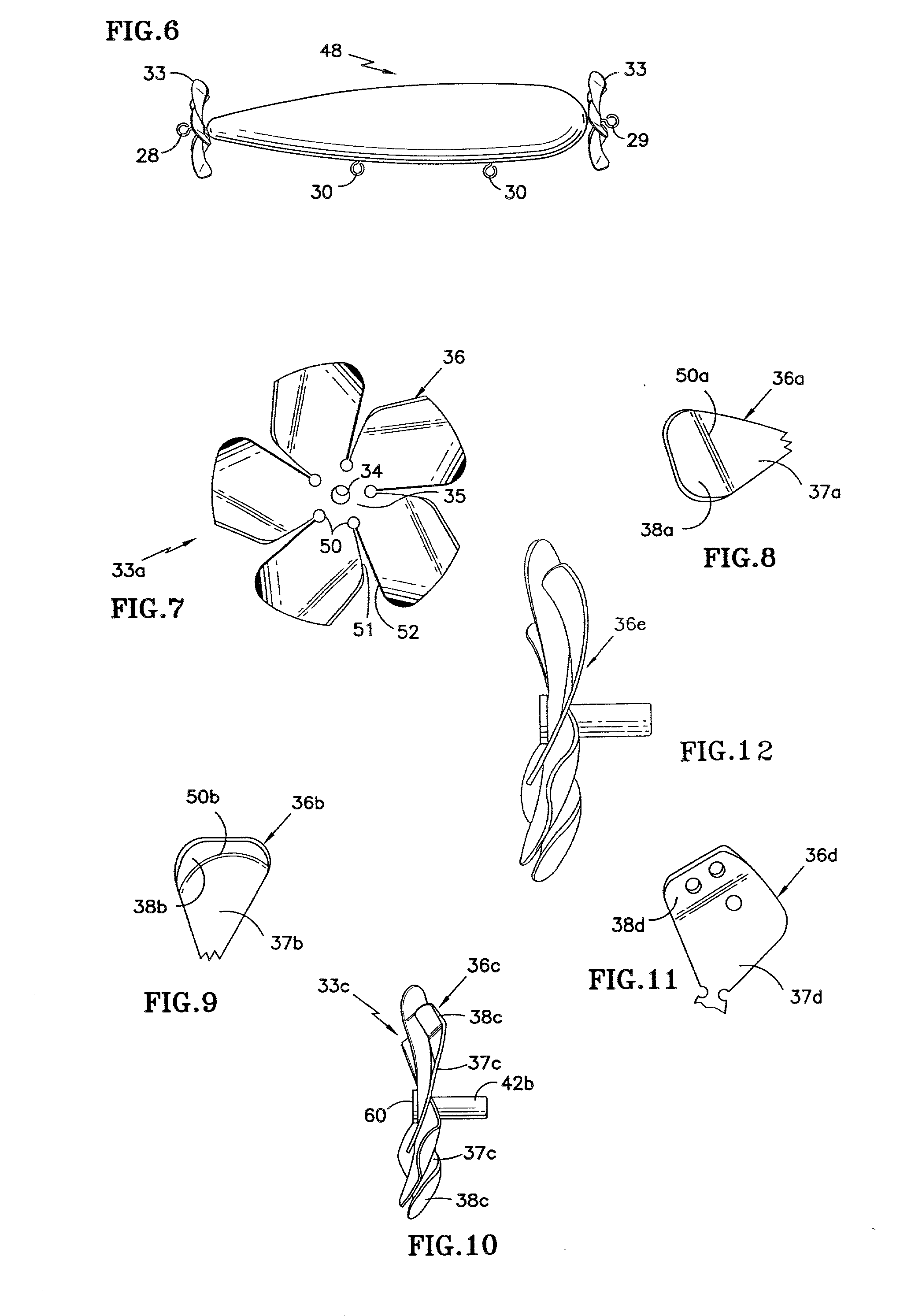

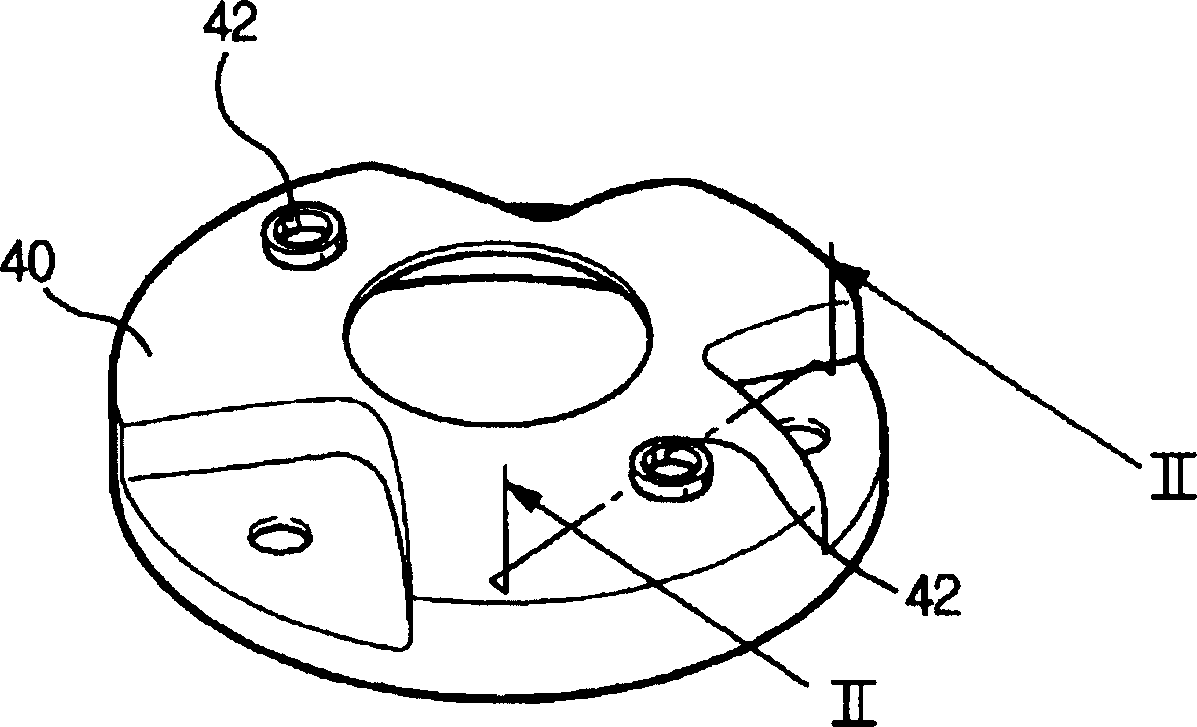

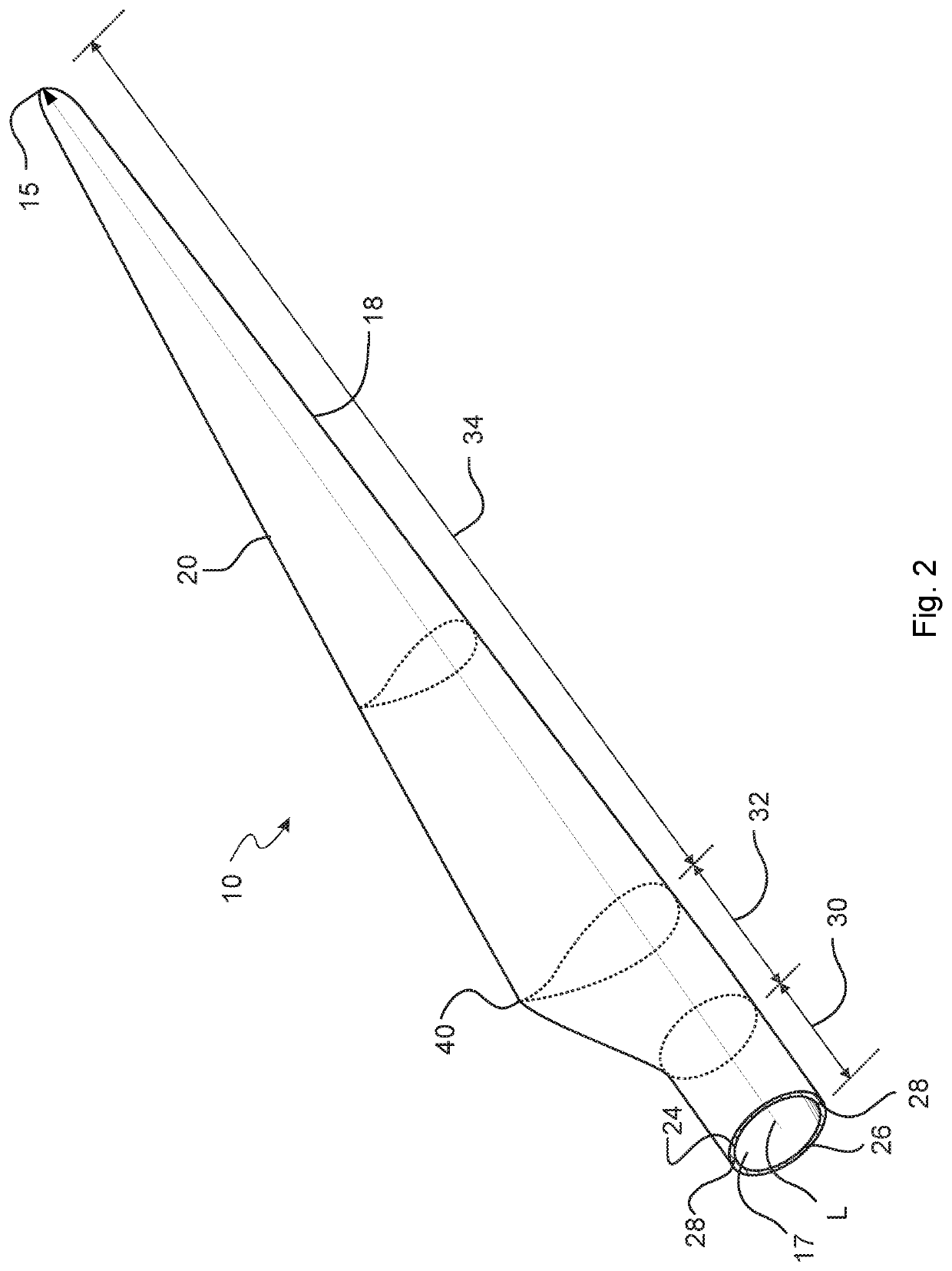

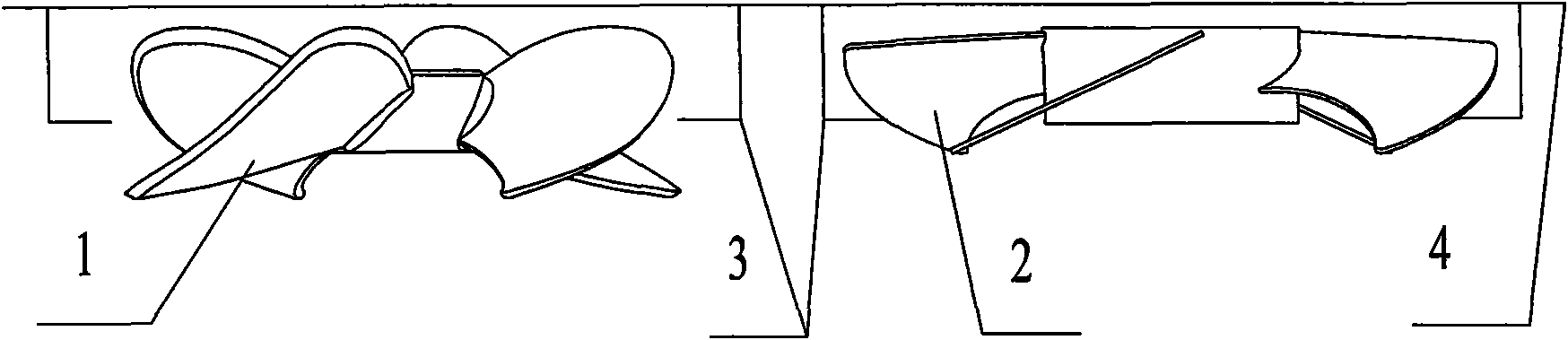

Top water lure with highly active propeller

A propeller 33 is disposed on a bearing collar 42 to rotate about a shaft 10 of a lure 32. The propeller has a plurality of blades 36, each having a proximal portion 37 with a first degree of pitch and a distal portion 38 having a second degree of pitch which is different than said first degree of pitch. The blades may have distal ends which have the same direction of pitch as the proximal ends, or distal ends which have pitch opposite to that of the proximal ends. The blades may have straight bends or curved bends between the proximal and distal portions, and each blade may comprise a single, smoothly curvilinear surface. The blades may have one or more holes of various sizes in one or more blades of each propeller, either in the distal portion or the proximal portion of the blades. One or more propellers may be mounted on buzz baits, top water lures including plugs, and on other lures.

Owner:SABINE KENNETH P

Audio outputting device, audio outputting method, noise reducing device, noise reducing method, program for noise reduction processing, noise reducing audio outputting device, and noise reducing audio outputting method

ActiveUS8422691B2Intuitive effectImprove noise reductionEar treatmentHeadphones for stereophonic communicationOutput deviceNoise reduction

Disclosed herein is an audio outputting device for switching a plurality of processes to perform a process on an audio signal, and acoustically reproducing and outputting the audio signal, the audio outputting device including, a control section for, when changing a process performed on an audio signal from one process to another process, stopping the one process on the audio signal, outputting sound based on the audio signal unprocessed by either of the one process and the other process, and performing the other process on the audio signal after passage of a predetermined period of time.

Owner:SONY CORP

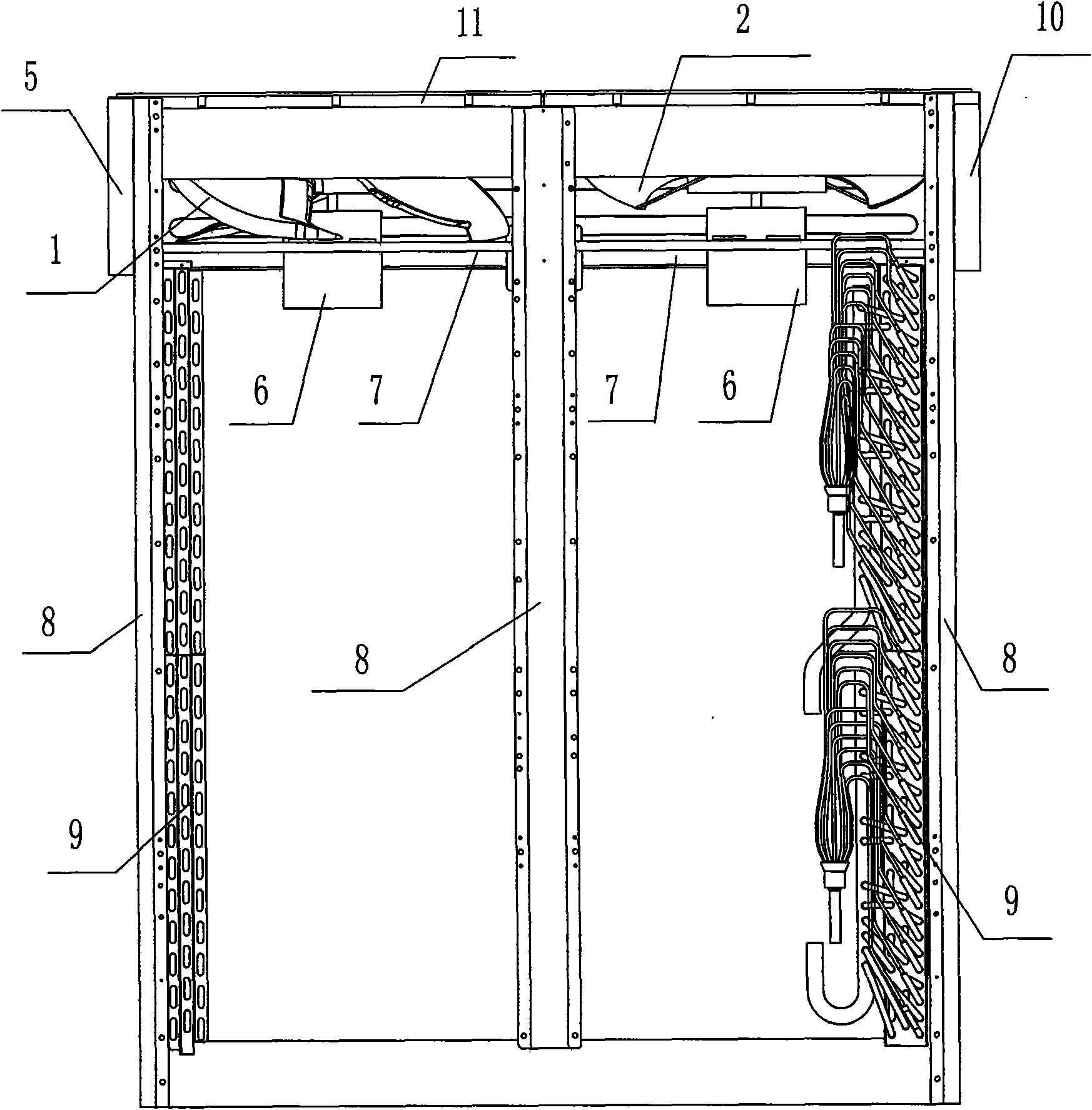

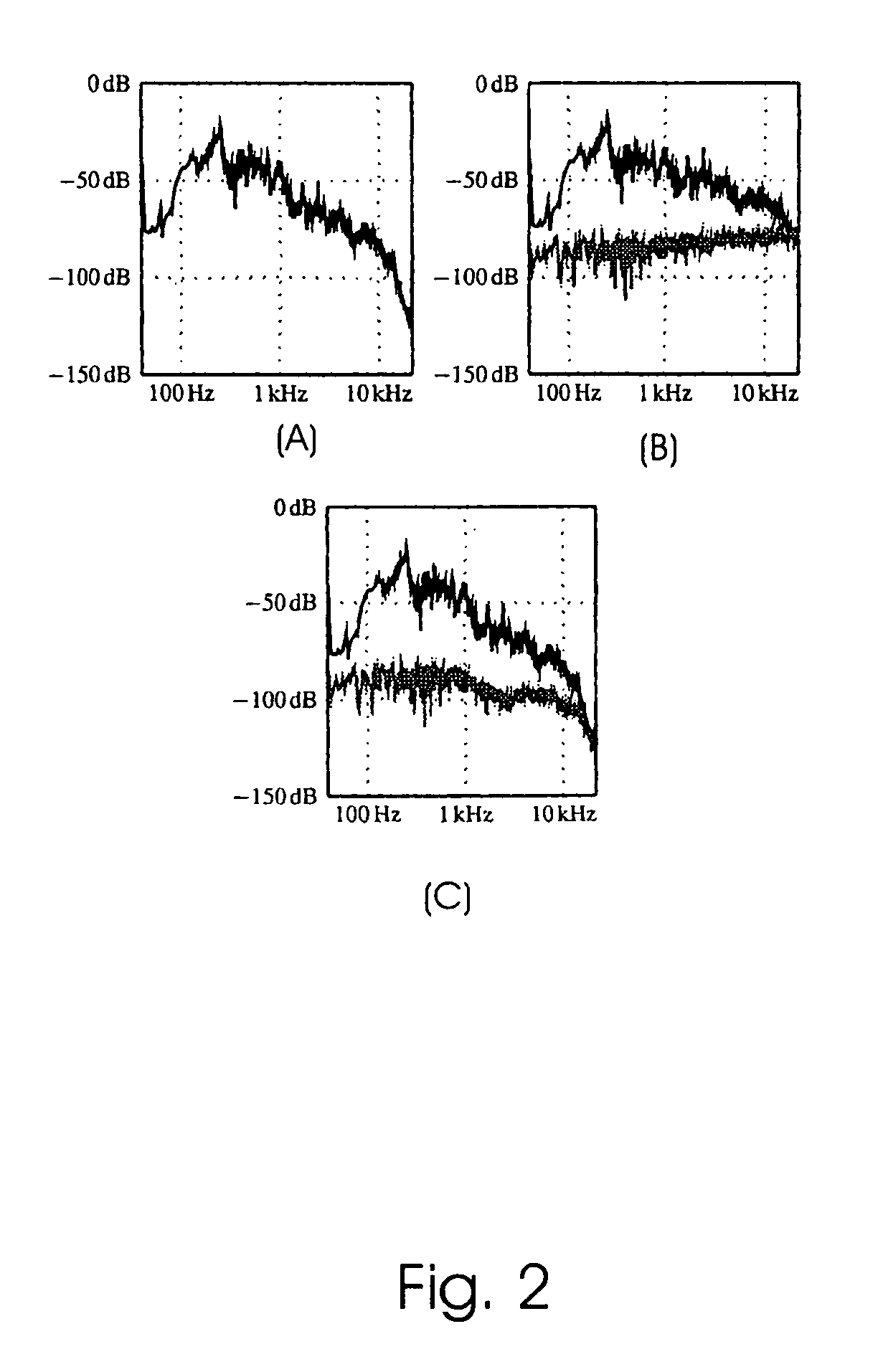

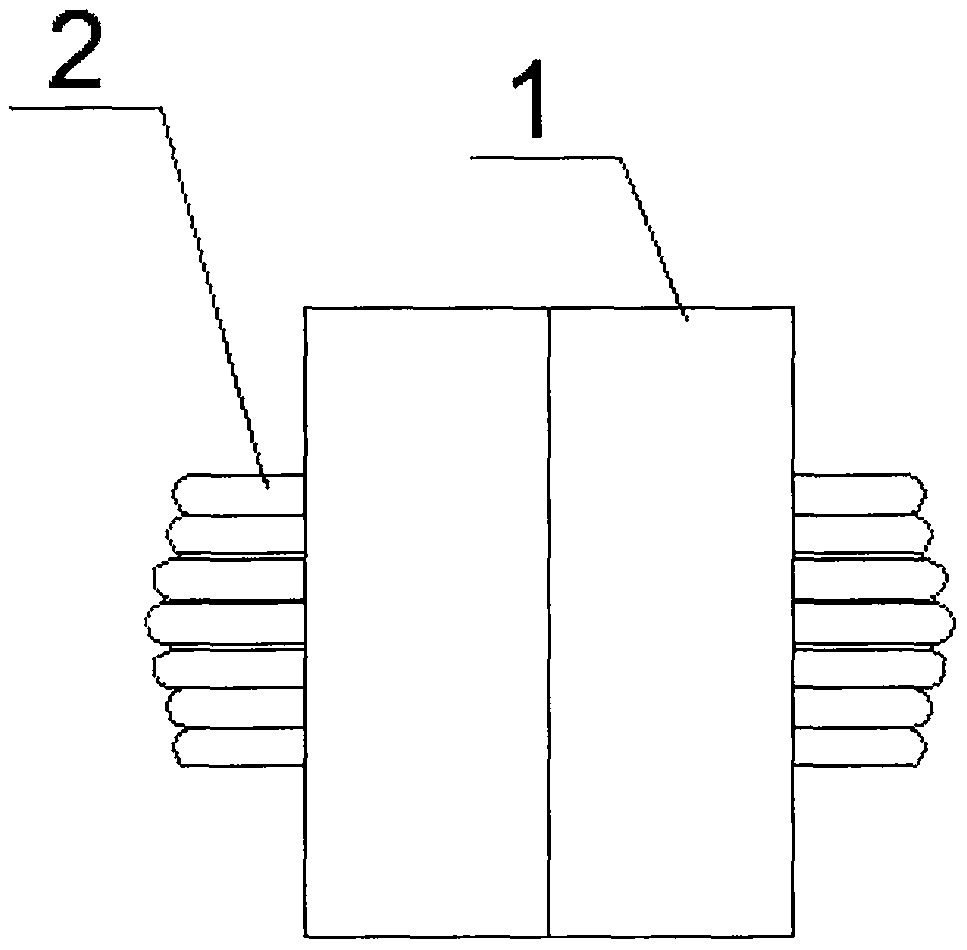

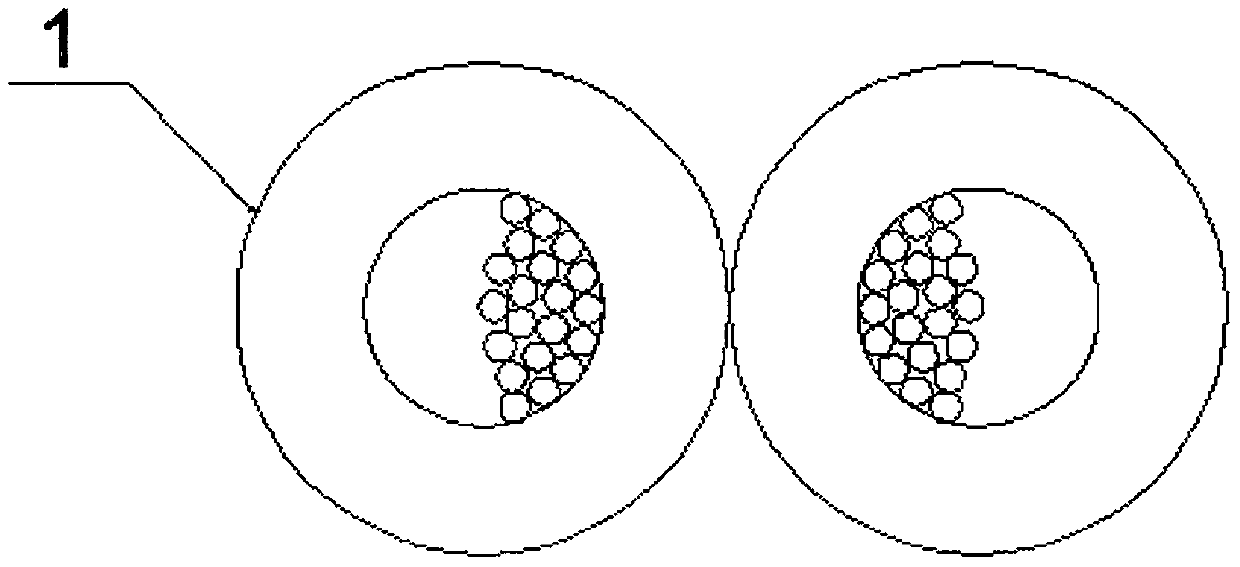

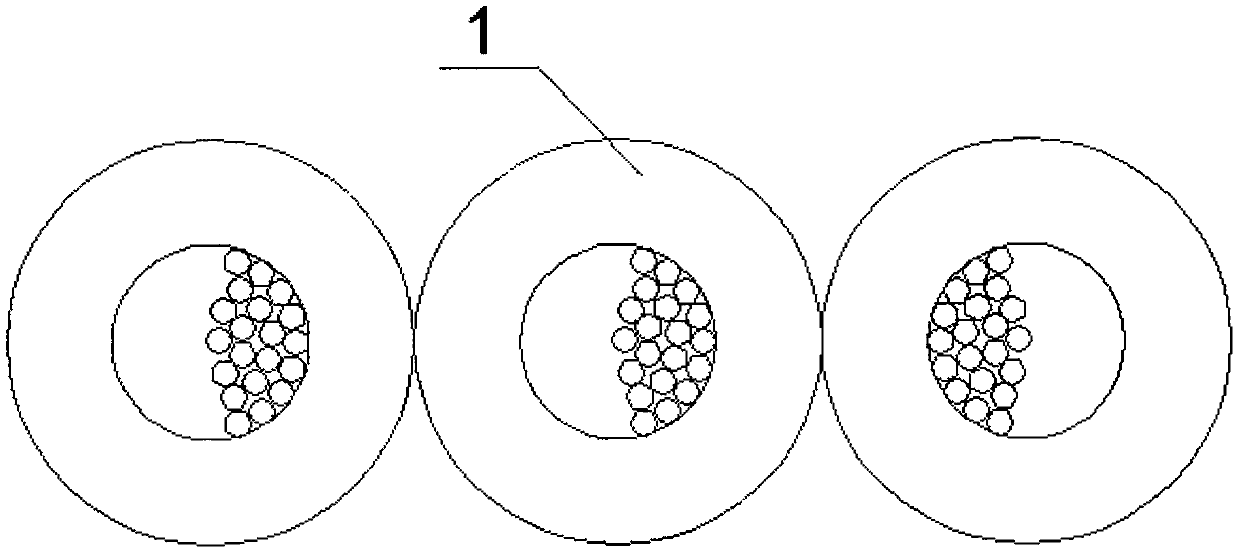

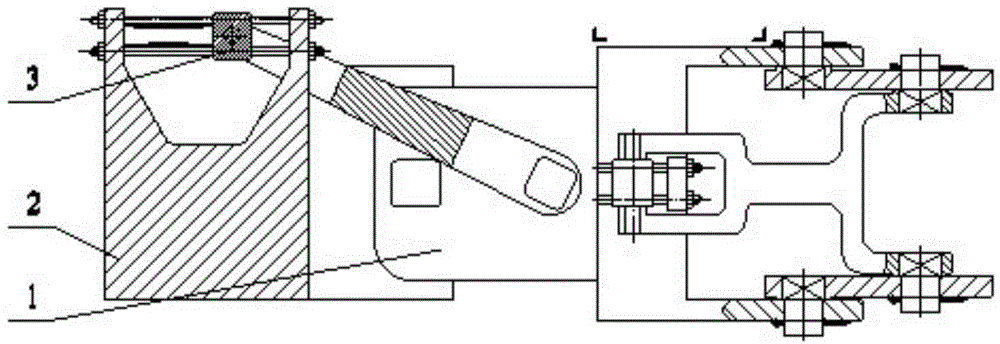

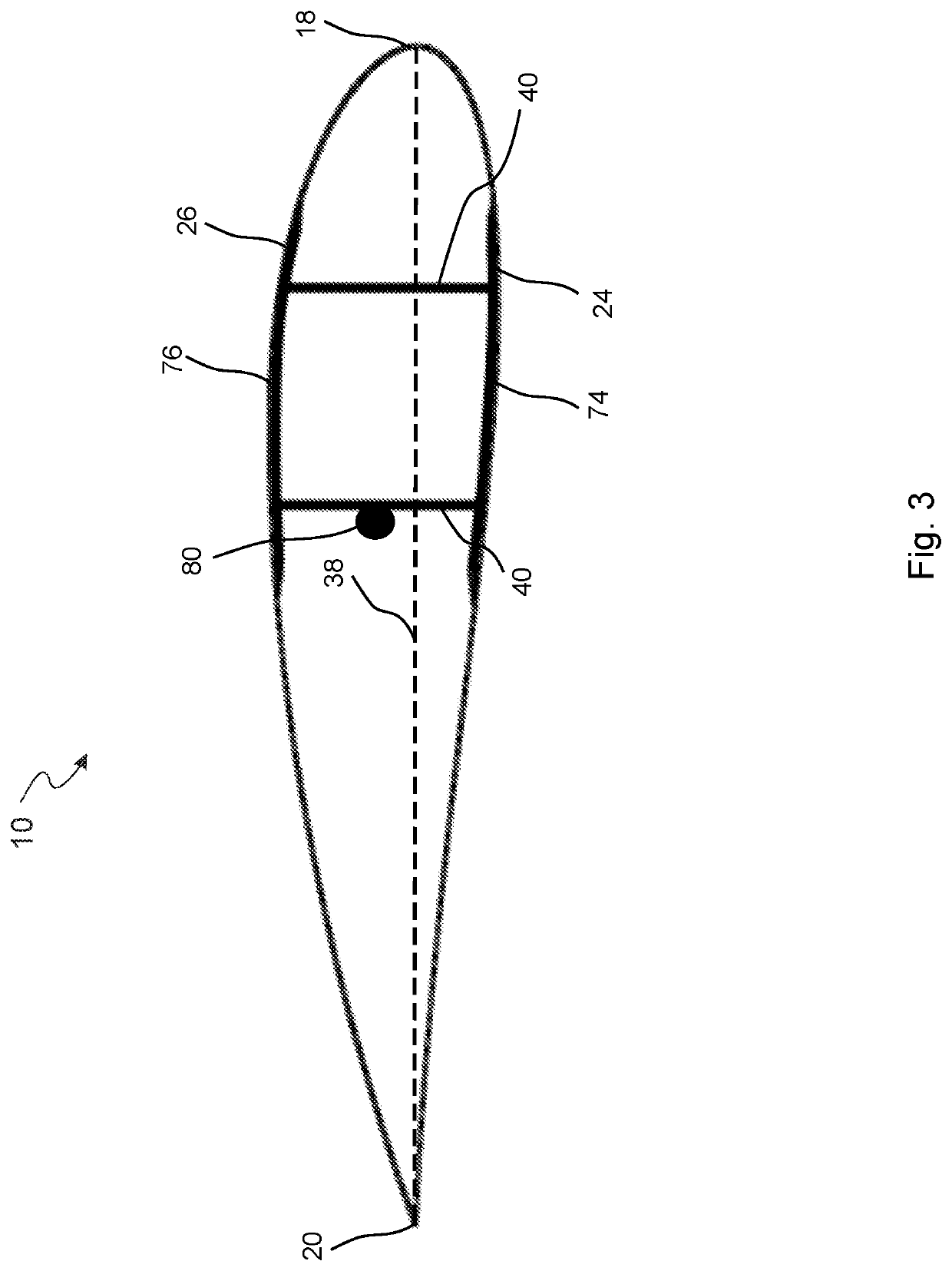

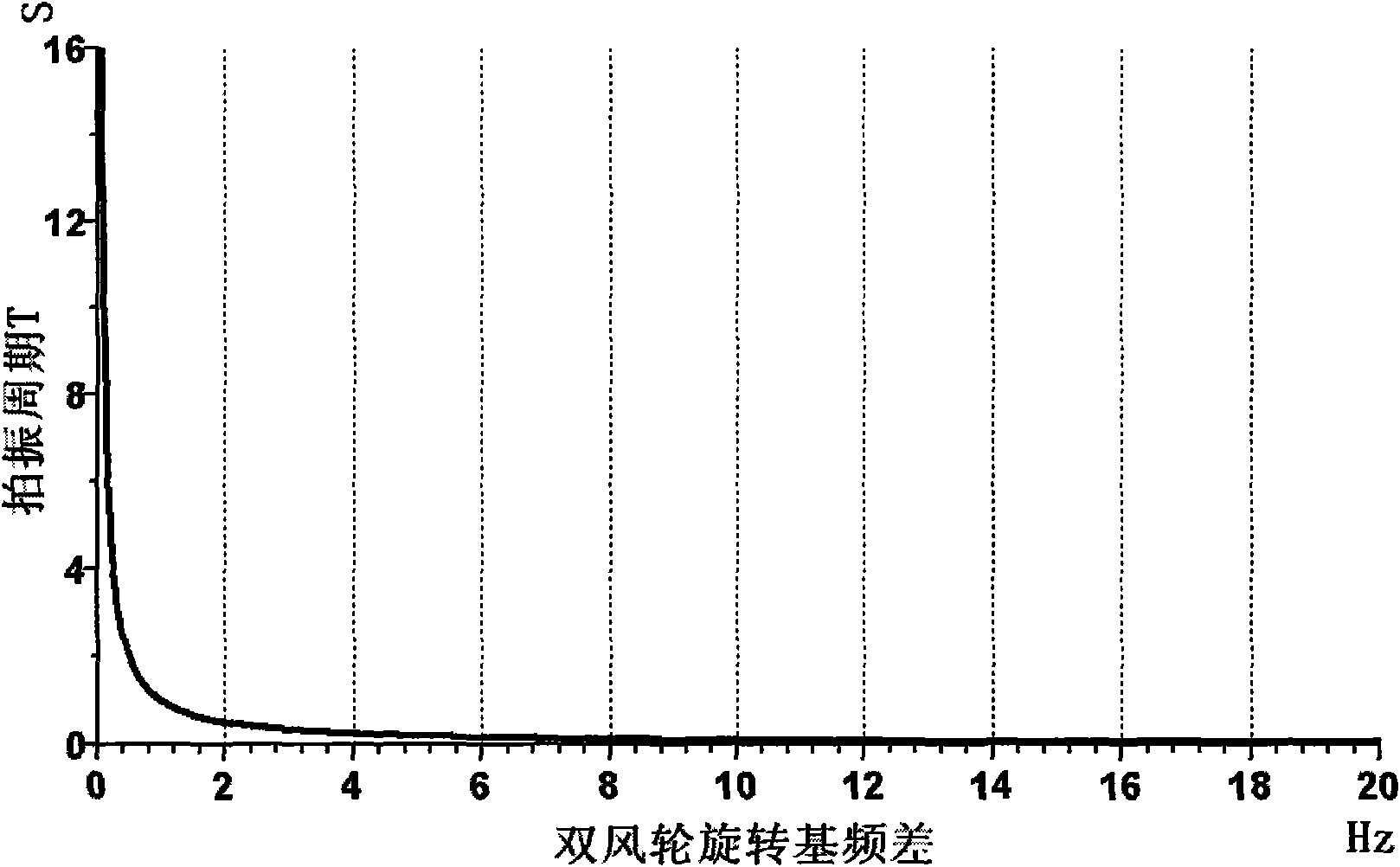

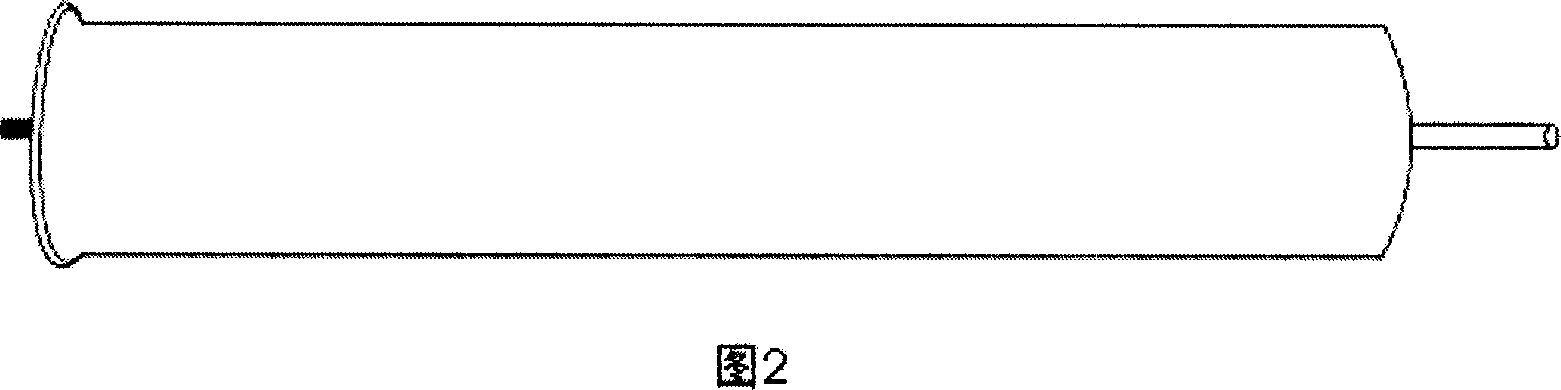

Double axial-flow wind wheel system

ActiveCN101644274AImprove sound qualityIngenious designPump componentsPump installationsEngineeringMachining system

The invention provides a double axial-flow wind wheel system, comprising a first axial-flow wind wheel (1) and a second axial-flow wind wheel (2); wherein the rotate speed of the first axial-flow windwheel (1) is N1 circle / minute, the number of blade is Z1, and rotating basic frequency F1=Z1XN1 / 60 Hz; and the rotate speed of the second axial-flow wind wheel (w) is N2 circle / minute, the number ofblade is Z2, and rotating basic frequency F2=Z2XN2 / 60 Hz. The system is characterized in that the rotating basic frequency between the first axial-flow wind wheel (1) and the second axial-flow wind wheel (2) is in the range of 4-20 Hz. When being used in an outer machine of an air conditioning room with top wind out structure, side wind out structure or oblique upper wind out structure, because the rotating basic frequency between the first axial-flow wind wheel (1) and the second axial-flow wind wheel (2) is from 4 to 20 Hz, the system can change the rotating noise voice pressure and the voice powder of the double axial-flow wind wheel, thereby greatly weakening or completely removing the beat vibration formed by overlapping the rotating noise of the two wind wheels, obviously improving the tone quality of the outer machine system of the double axial-flow wind wheel, effectively preventing the metal plate structure from resonating, and reaching the aim of reducing the vibration and improving the reliability of the whole machine.

Owner:MIDEA GRP CO LTD

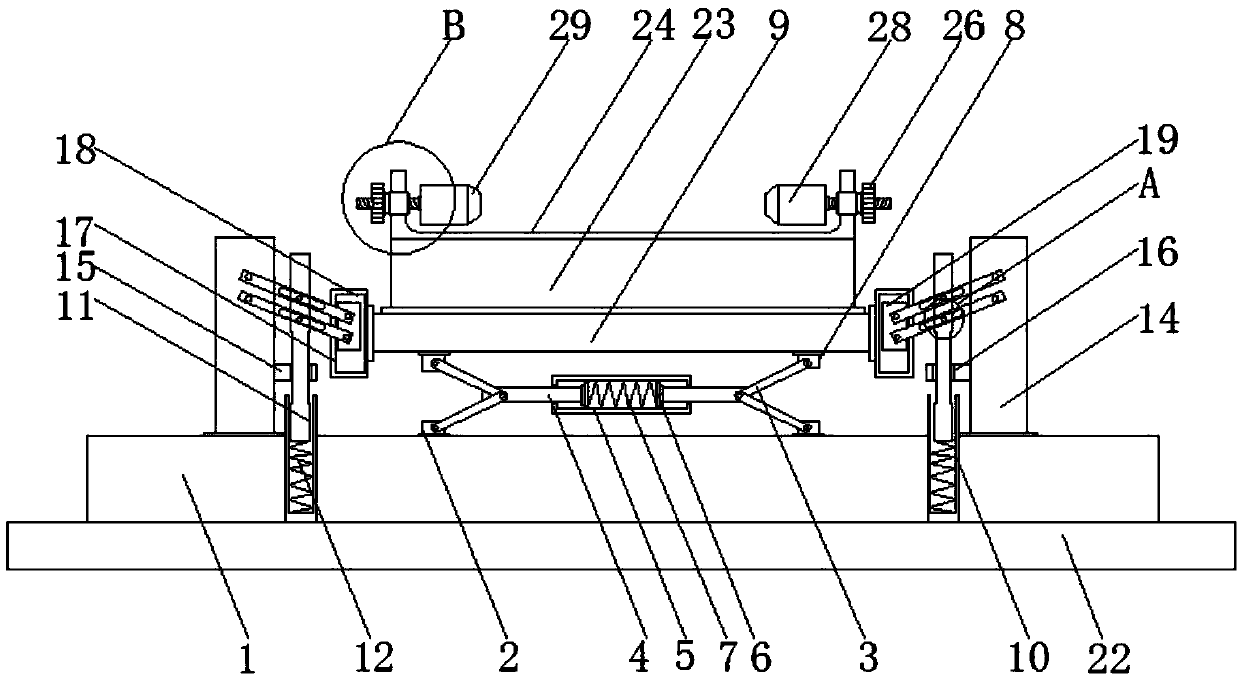

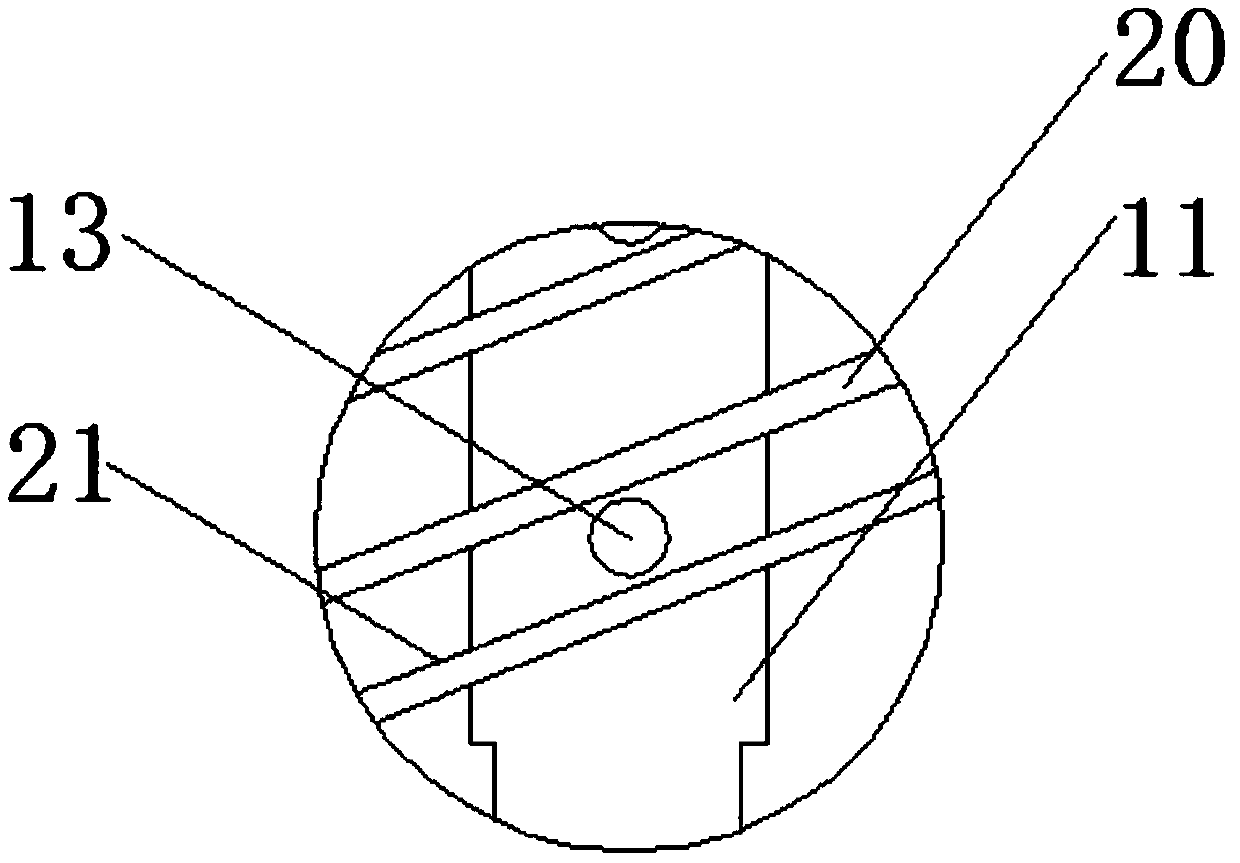

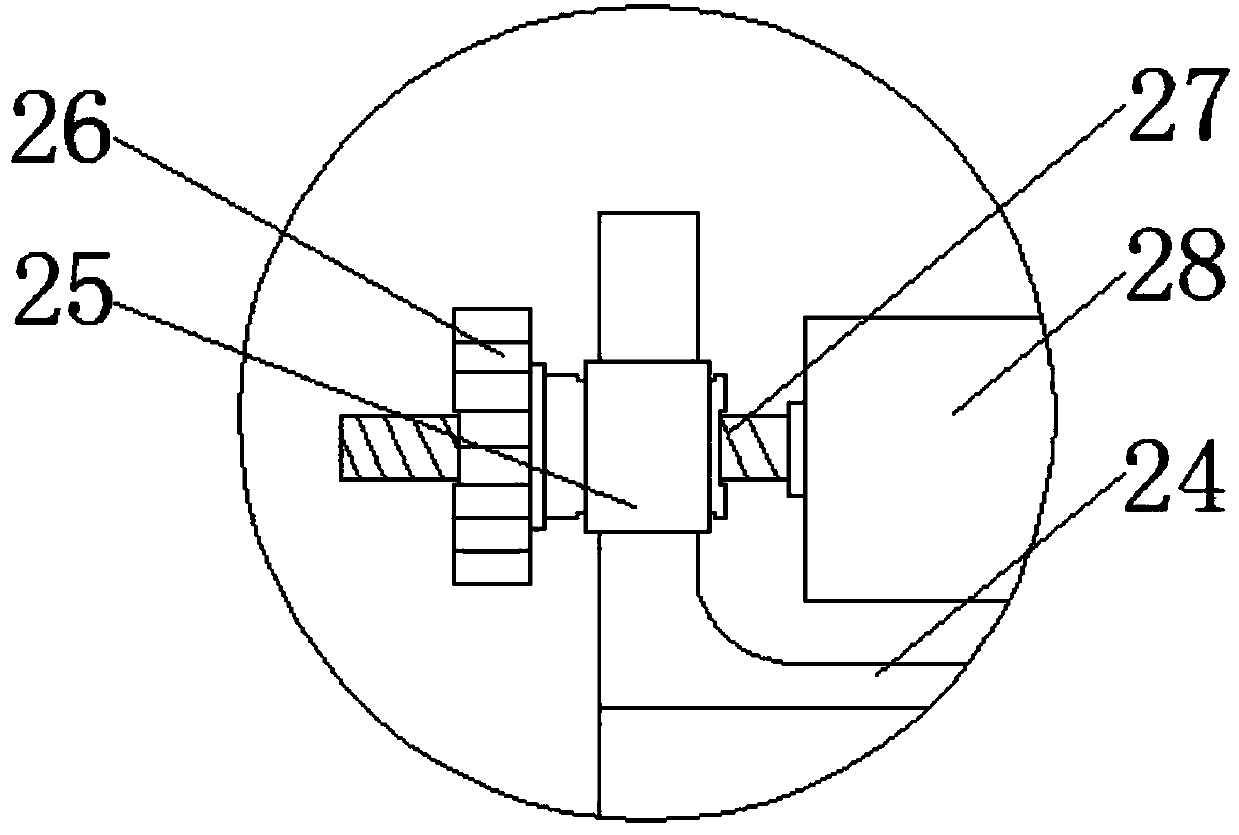

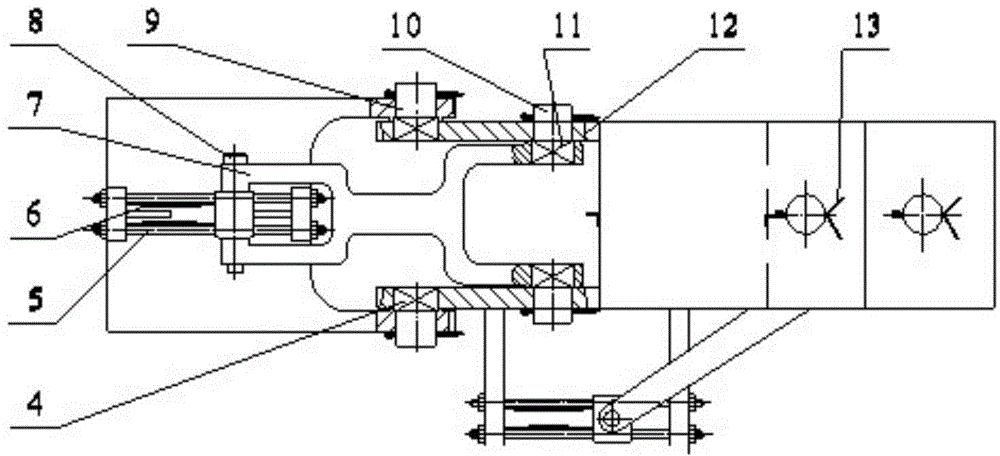

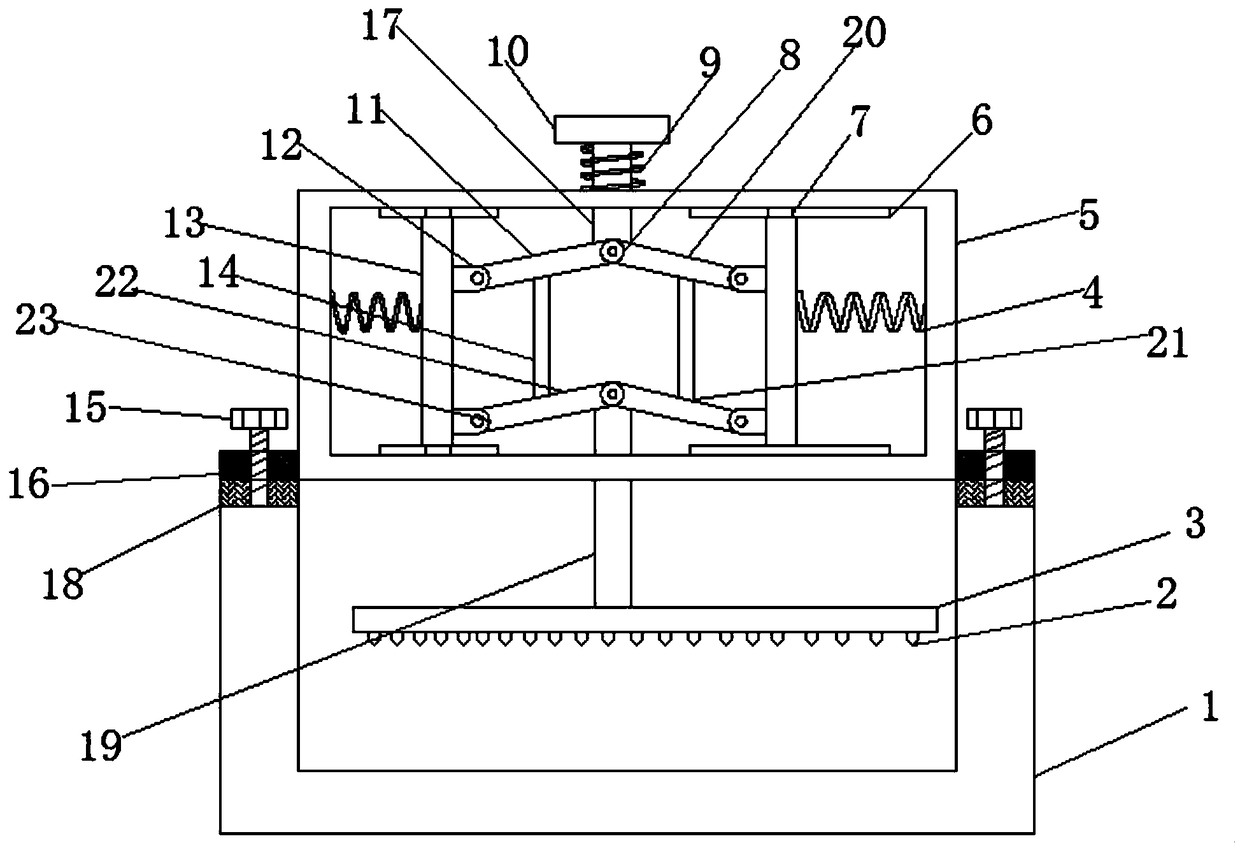

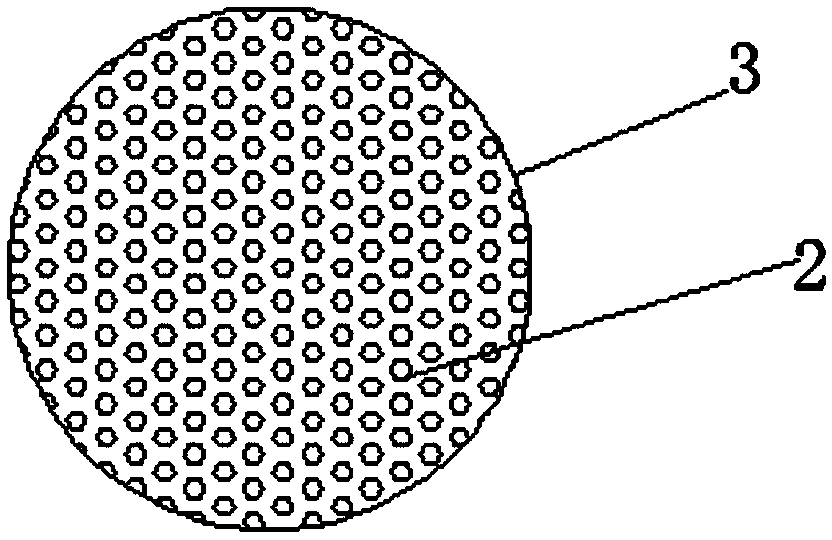

High-stability centrifugal machine pedestal for laboratory

InactiveCN107626459AChanging the Vibration ProblemReduce vibrationCentrifugesEngineeringLaboratory facility

The invention discloses a high-stability centrifugal machine pedestal for a laboratory. The high-stability centrifugal machine pedestal for the laboratory comprises a pedestal; the top of the pedestalis fixedly connected with a first shaft block; the front side of the first shaft block is rotatably connected with a connecting rod; one end of the rotating rod is rotatably connected with a pressurerod; the surface of the pressure rod is in sliding connection with a first casing pipe; one end of the pressure rod is fixedly connected with cushions; each of the opposite sides of the two cushionsis fixedly connected with a first spring; one end of the connecting rod is fixedly connected with a supporting plate through a second shaft block; and the front side of the pedestal is fixedly connected with a second casing pipe. The invention relates to the technical field of biology. The high-stability centrifugal machine pedestal for the laboratory solves the problem of vibration of the centrifugal machine caused by high rotating speed of the centrifugal machine during work, reduces noise caused by vibration, has high stability, eliminates a certain potential safety hazard, improves the experimental environment, is favorable for conduction of the experiment, and guarantees the experimental result.

Owner:安徽普生源生物科技有限公司

Top water lure with highly active propeller

A propeller 33 is disposed on a bearing collar 42 to rotate about a shaft 10 of a lure 32. The propeller has a plurality of blades 36, each having a proximal portion 37 with a first degree of pitch and a distal portion 38 having a second degree of pitch which is different than said first degree of pitch. The blades may have distal ends which have the same direction of pitch as the proximal ends, or distal ends which have pitch opposite to that of the proximal ends. The blades may have straight bends or curved bends between the proximal and distal portions, and each blade may comprise a single, smoothly curvilinear surface. The blades may have one or more holes of various sizes in one or more blades of each propeller, either in the distal portion or the proximal portion of the blades. One or more propellers may be mounted on buzz baits, top water lures including plugs, and on other lures.

Owner:SABINE KENNETH P

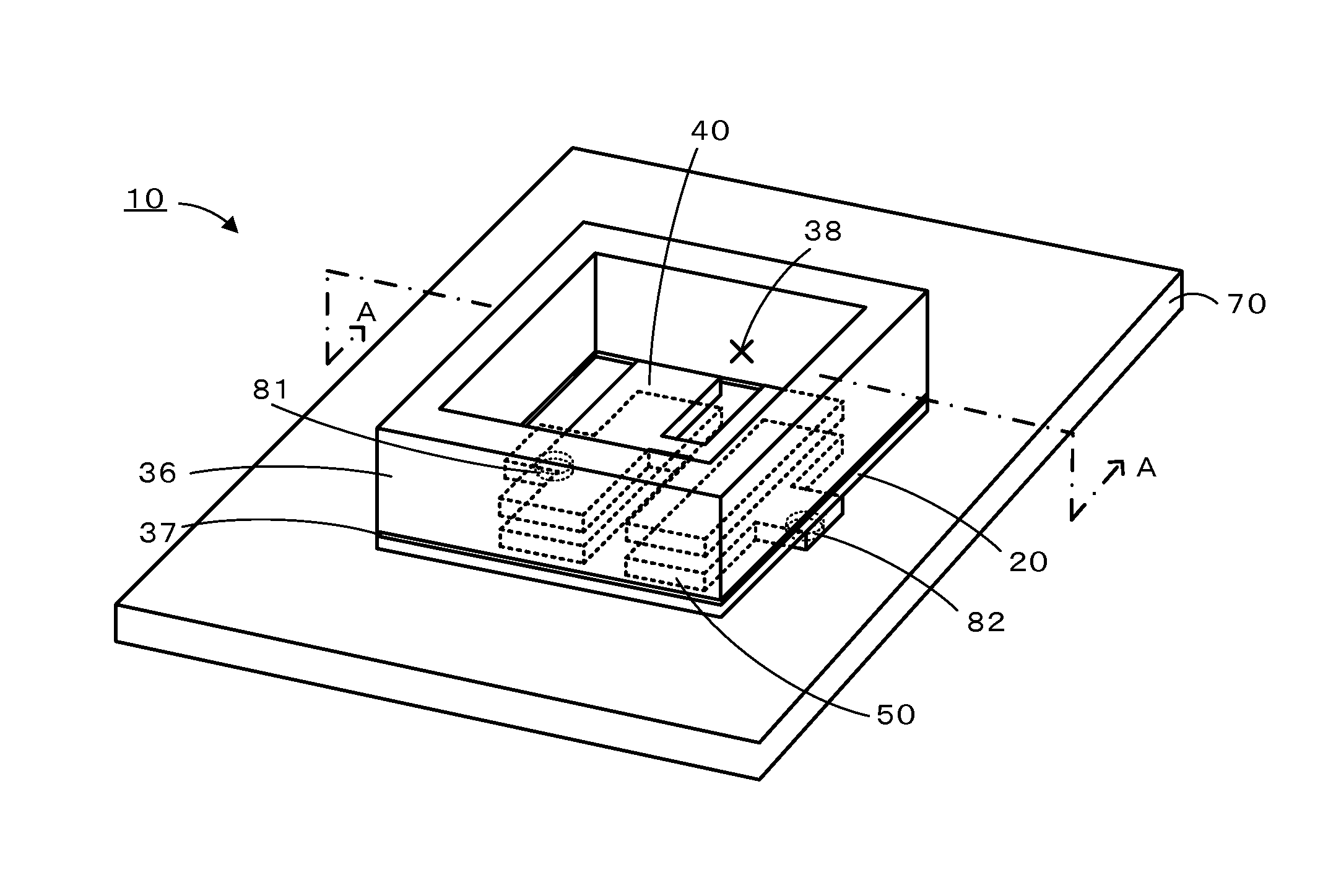

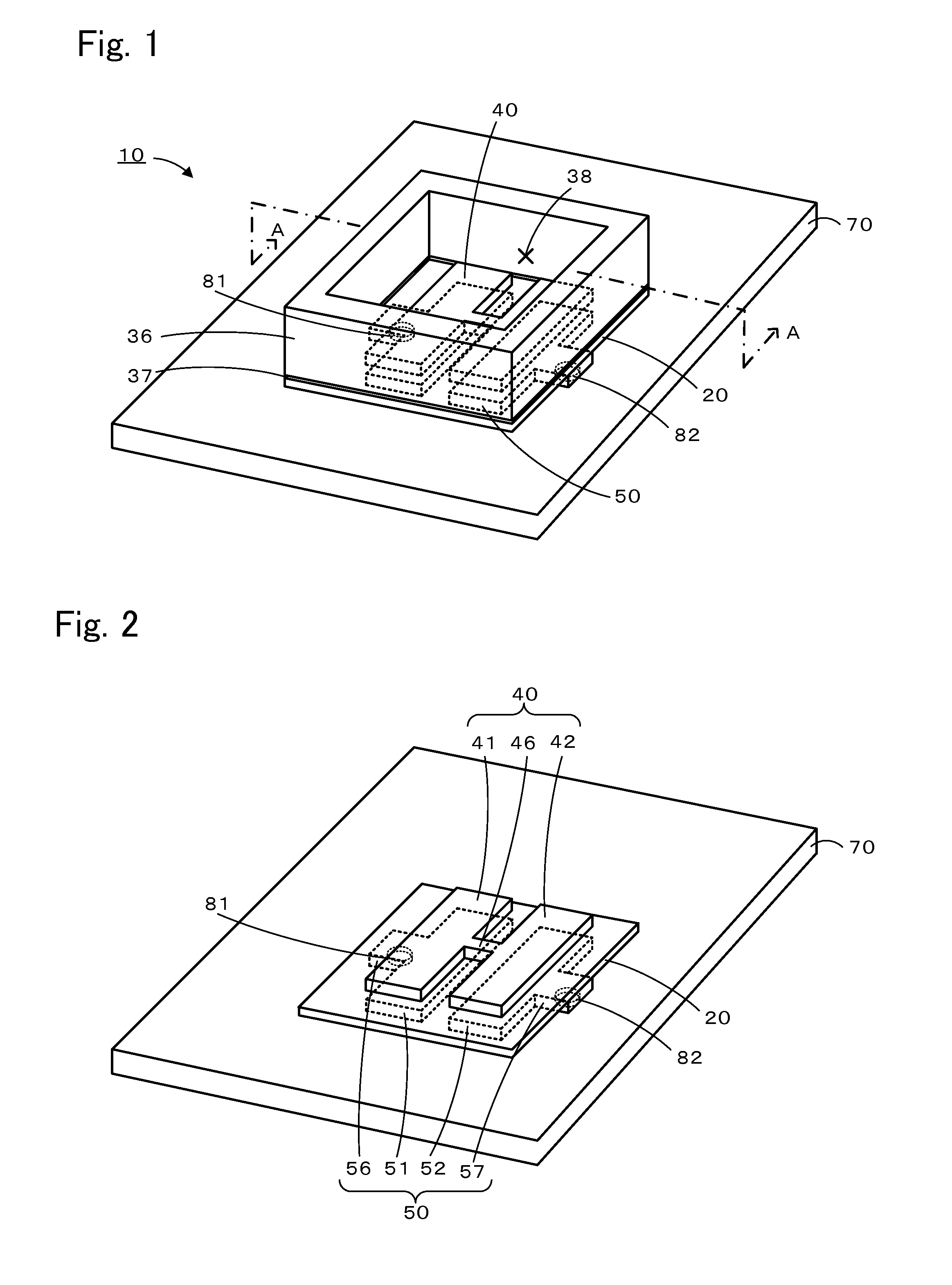

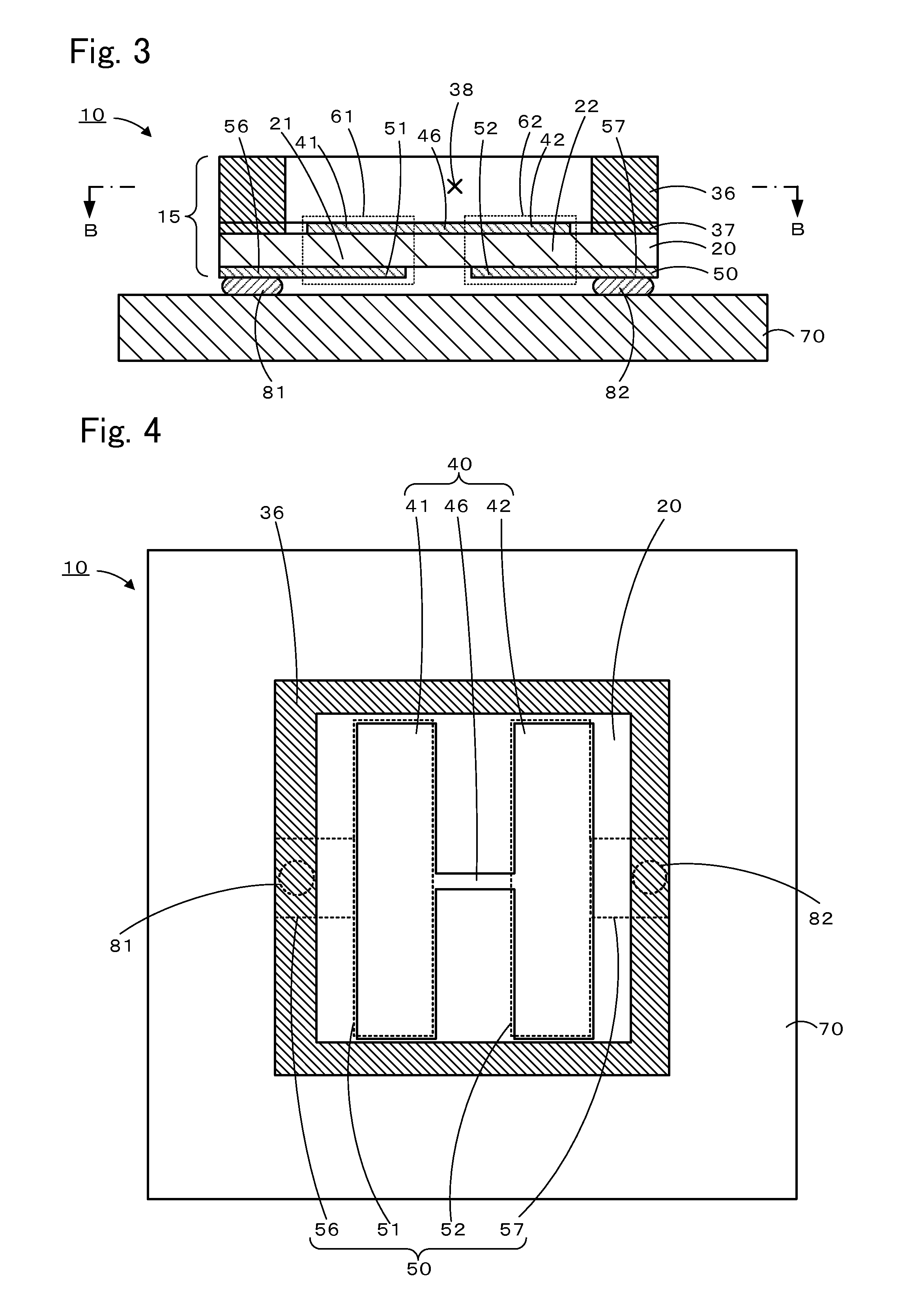

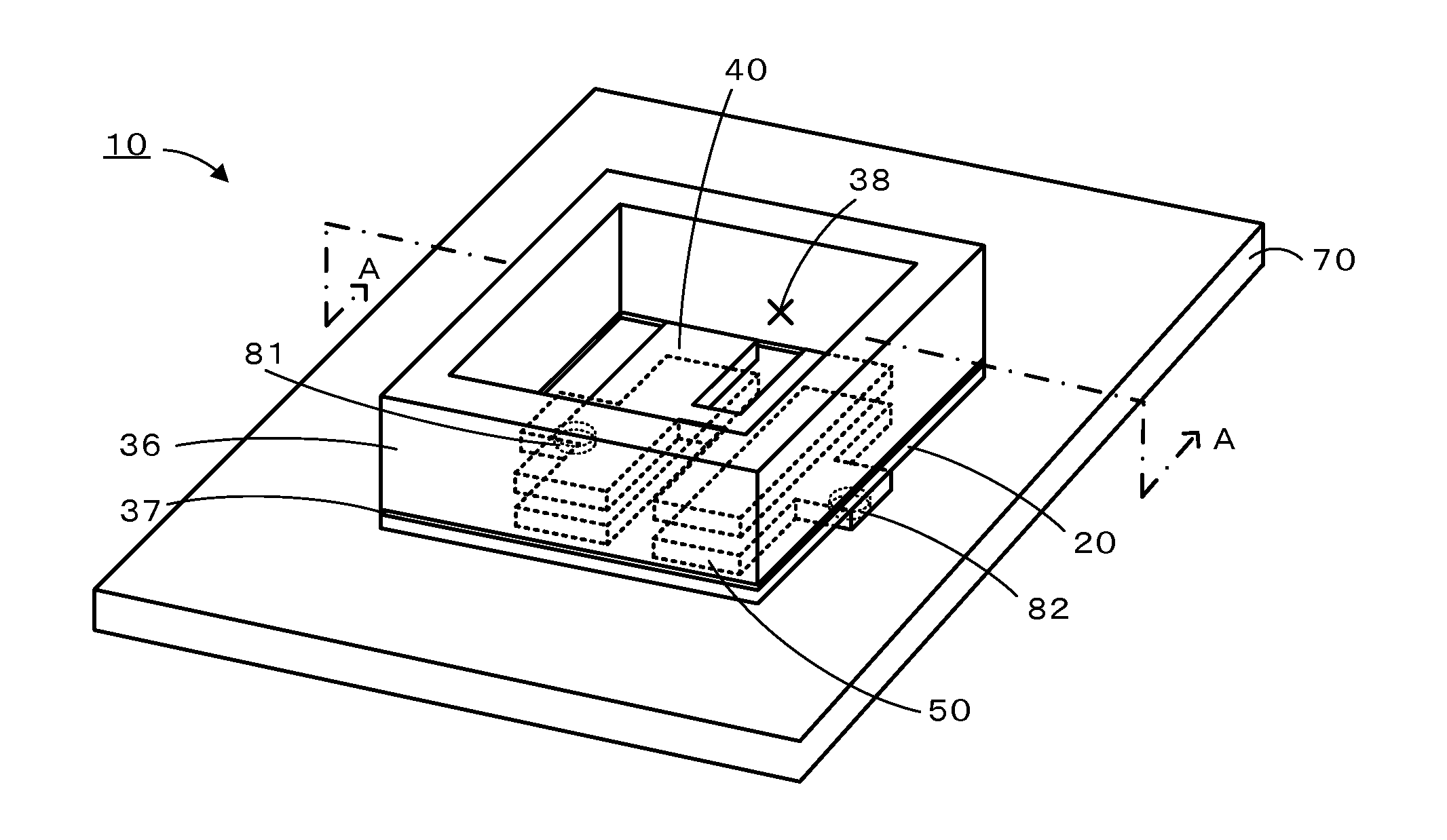

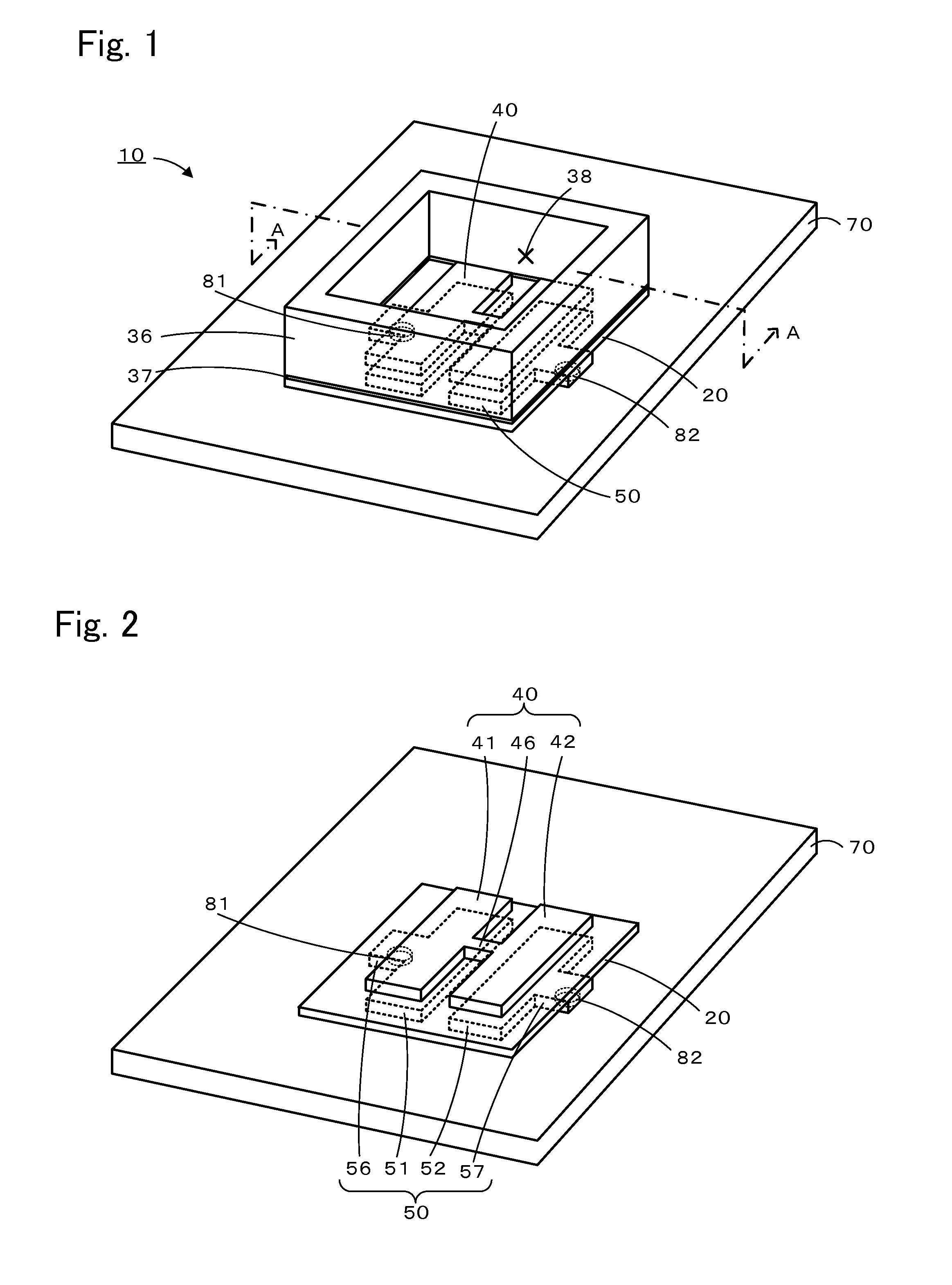

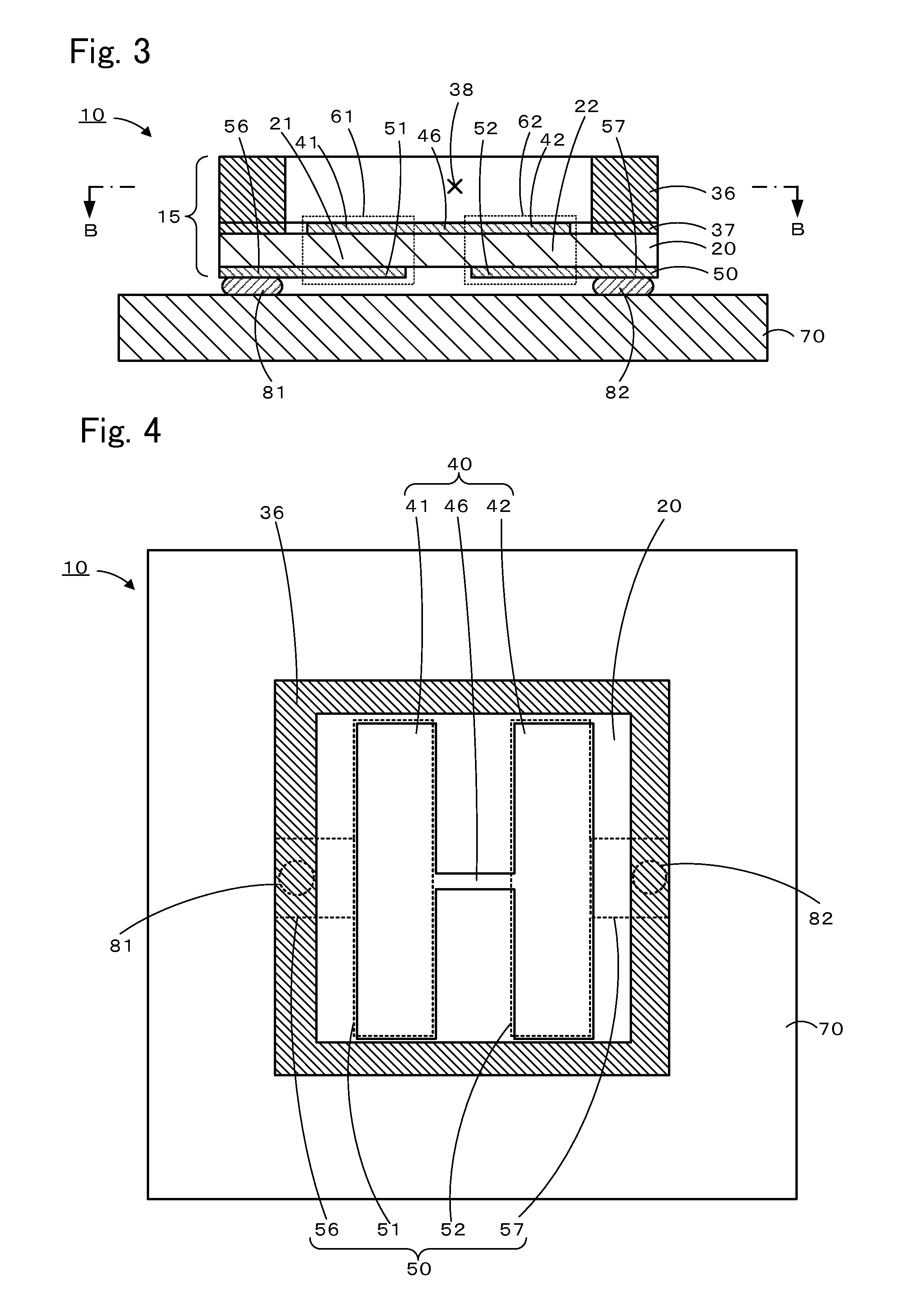

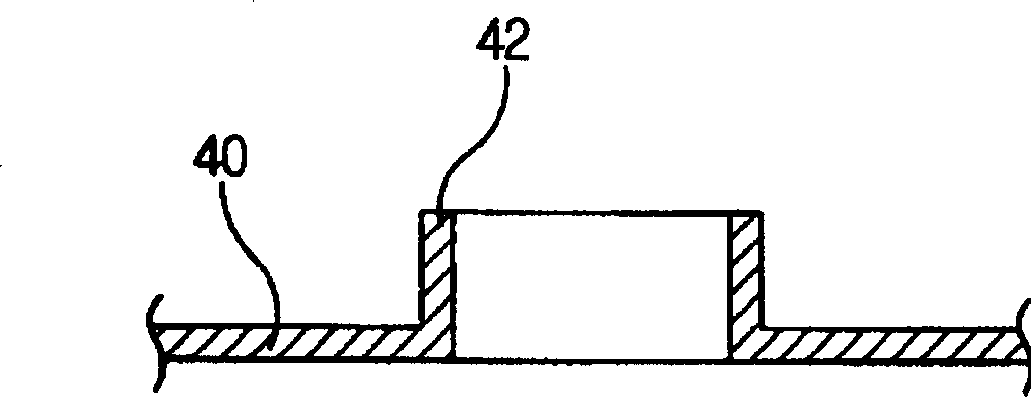

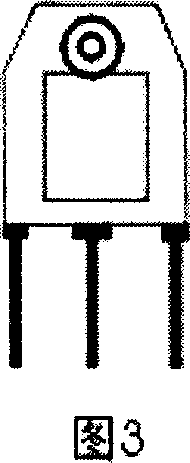

Infrared detection element, infrared detection module, and manufacturing method therefor

ActiveUS9267846B2Reduce thicknessAvoid deformationThermoelectric device with dielectric constant thermal changePyrometry using electric radation detectorsThermal expansionOptoelectronics

In an infrared detection element 15, a first substrate 36 is bonded to a front side of a pyroelectric substrate 20. Since the thermal expansion coefficient of the first substrate 36 is lower than that of the pyroelectric substrate 20, deformation of the pyroelectric substrate 20 due to thermal expansion can be suppressed by the first substrate 36. Further, since a thermal expansion coefficient difference D is 8.9 ppm / K or less, the thermal expansion coefficient between the first substrate 36 and the pyroelectric substrate 20 is not excessively large, and this can suppress deformation of the infrared detection element 15 due to the thermal expansion coefficient difference between the first substrate 36 and the pyroelectric substrate 20.

Owner:NGK INSULATORS LTD

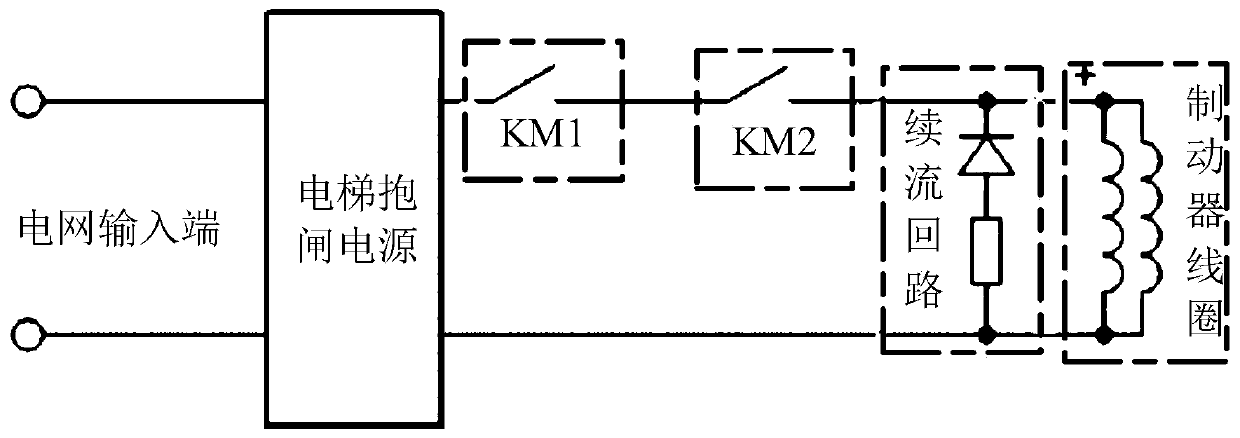

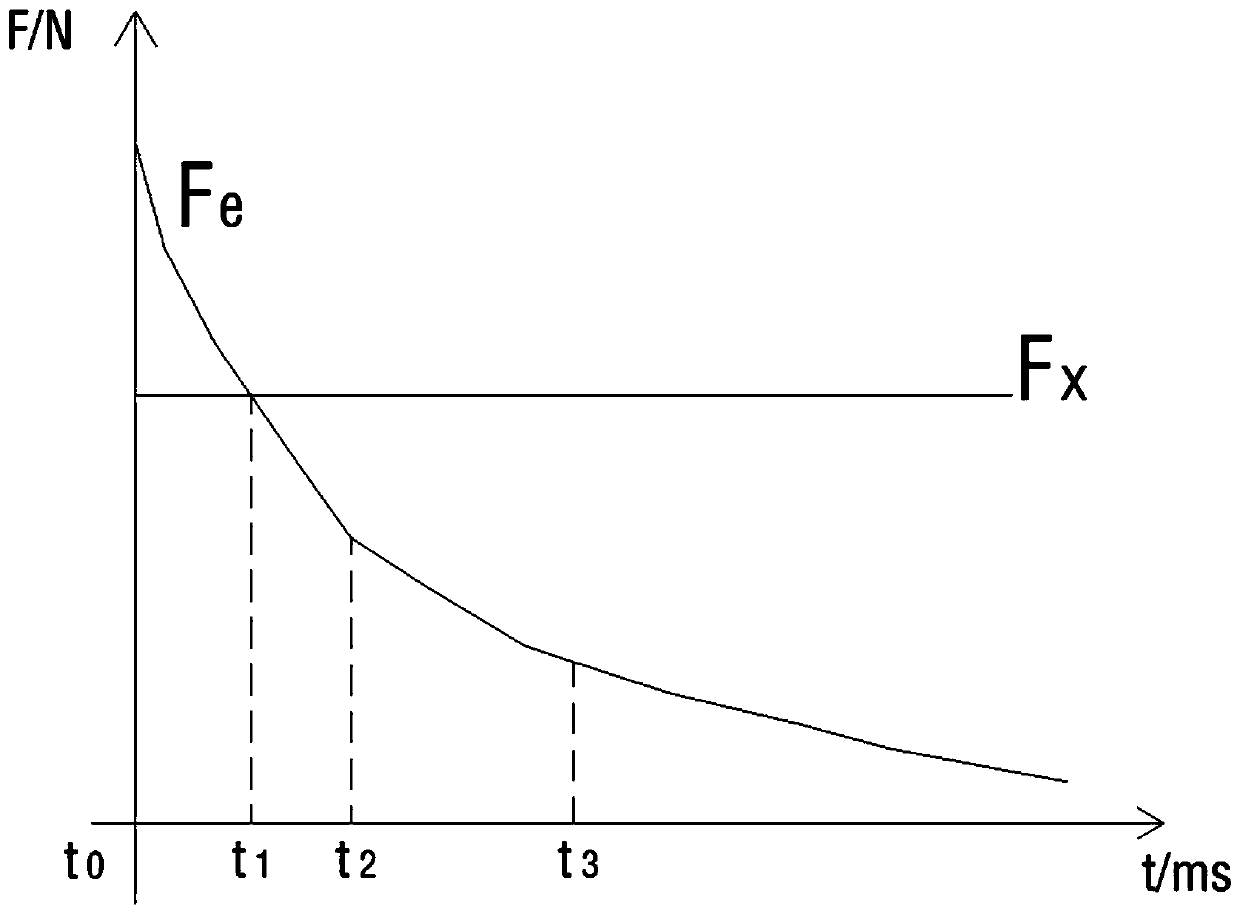

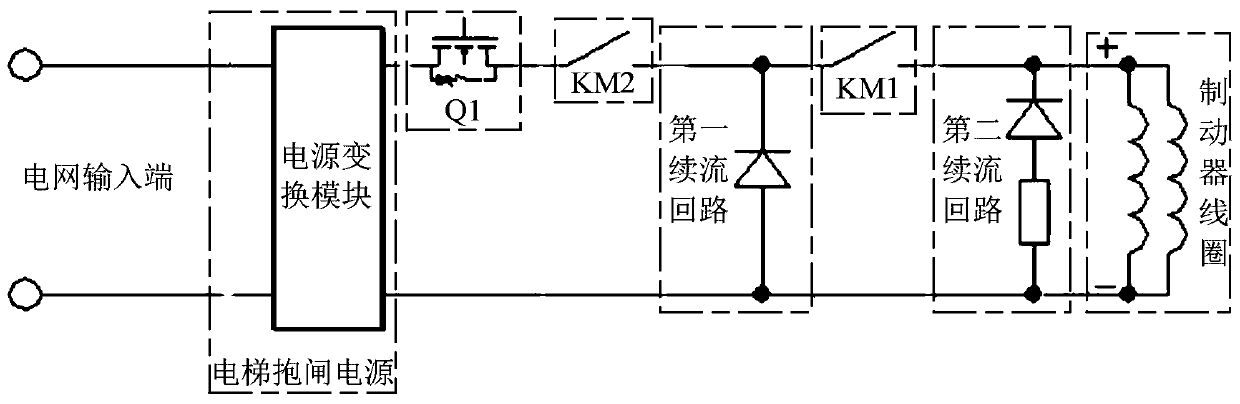

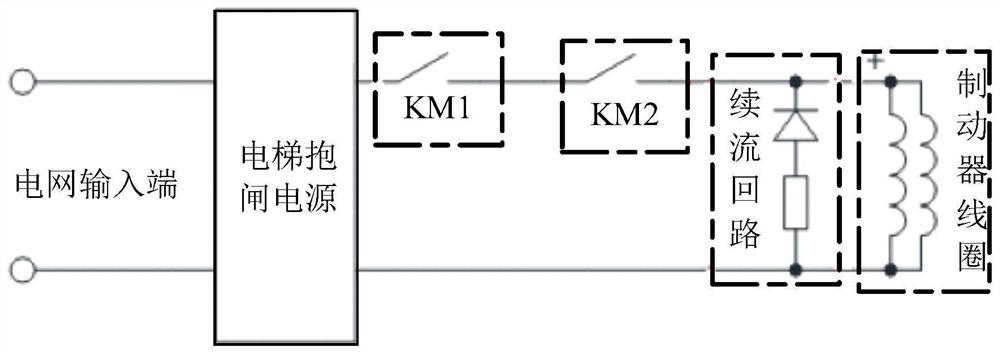

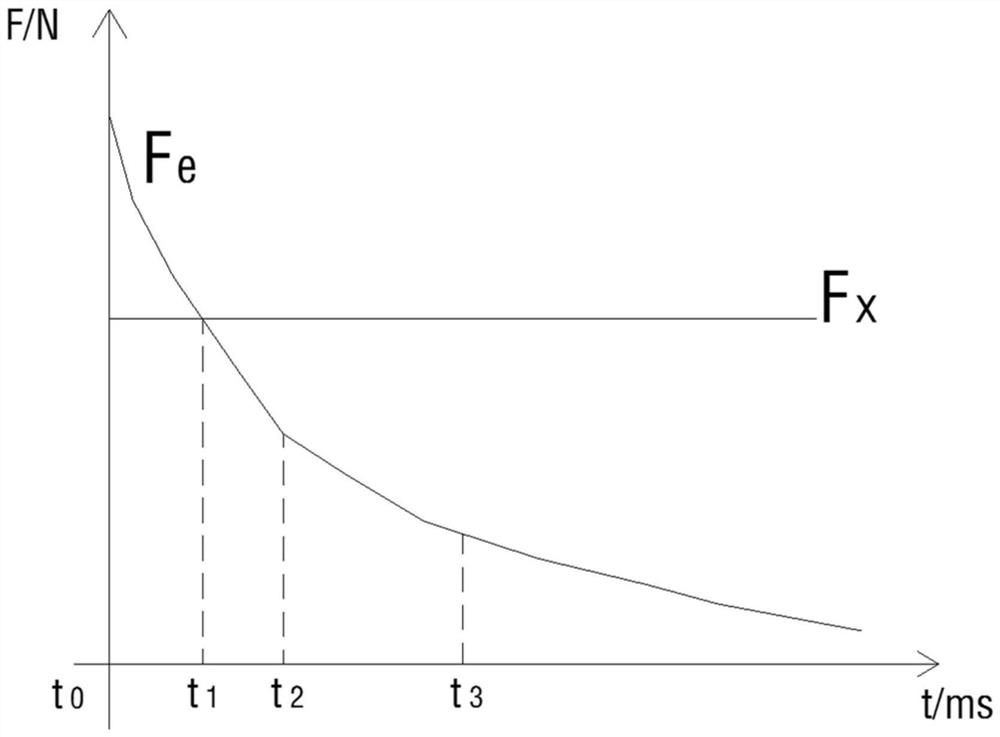

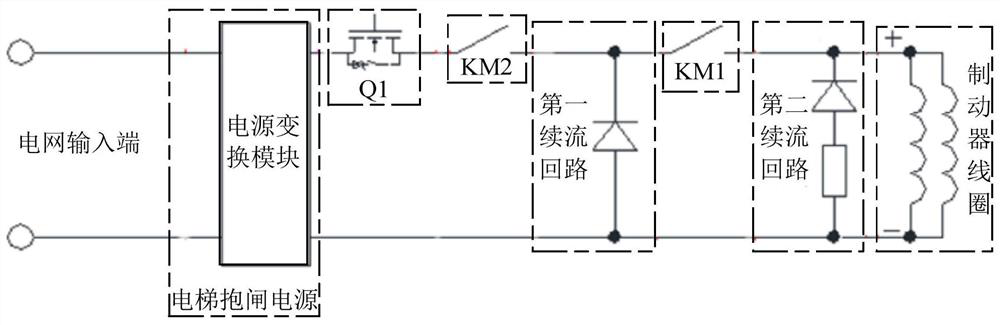

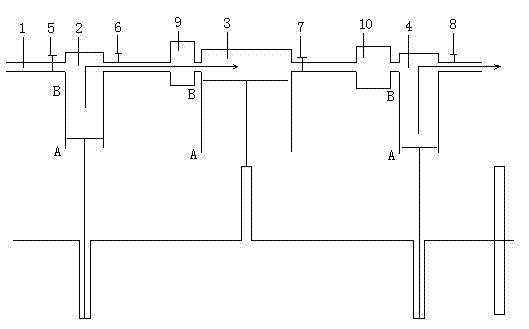

Elevator brake follow current control method, device and equipment and medium

ActiveCN111204631AChange release timeReduced emission noiseBrake actuating mechanismsElevatorsCurrent thresholdEngineering

The embodiment of the invention discloses an elevator brake follow current control method, device and equipment and a medium, and relates to the technical field of elevators. The elevator brake followcurrent control method comprises the steps that the elevator state and a control instruction corresponding to the elevator state are determined; and according to a control signal corresponding to thecontrol instruction, the brake coil current is subjected to chopping control till the brake coil current is reduced to the current threshold value corresponding to the elevator state. The brake coilcurrent is controlled through the control signal corresponding to the control instruction, the purpose of actively adjusting the electromagnetic force is achieved, accordingly, the brake releasing time and noise can be changed, accordingly, releasing noise reduction and releasing time shortening can be effectively considered, and the usage requirements of different brakes are met.

Owner:HITACHI BUILDING TECH GUANGZHOU CO LTD

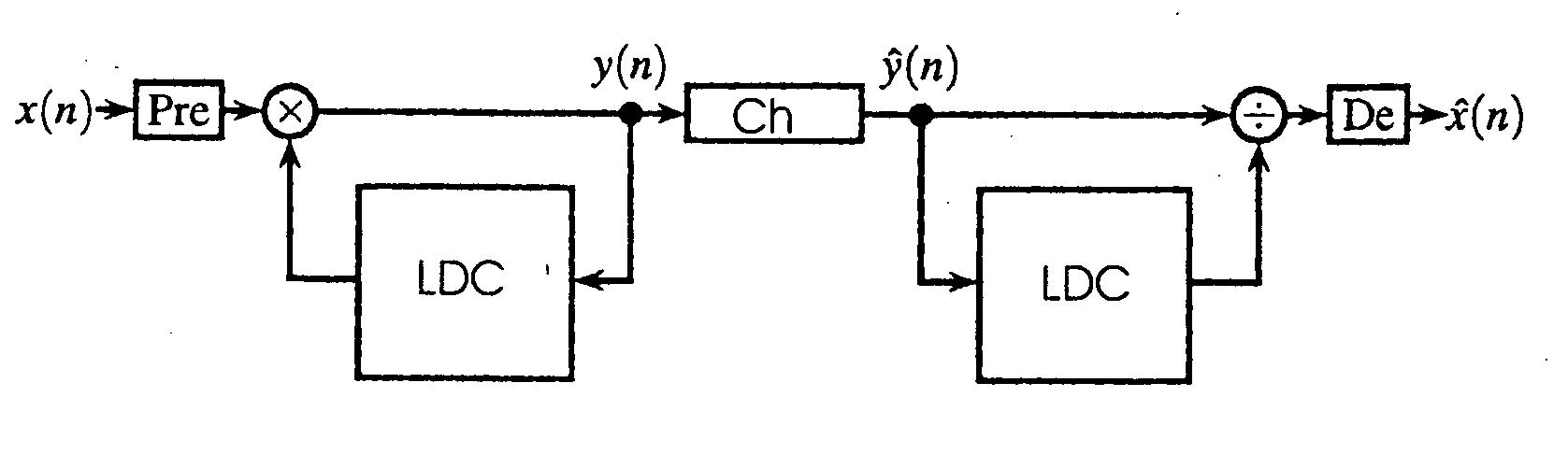

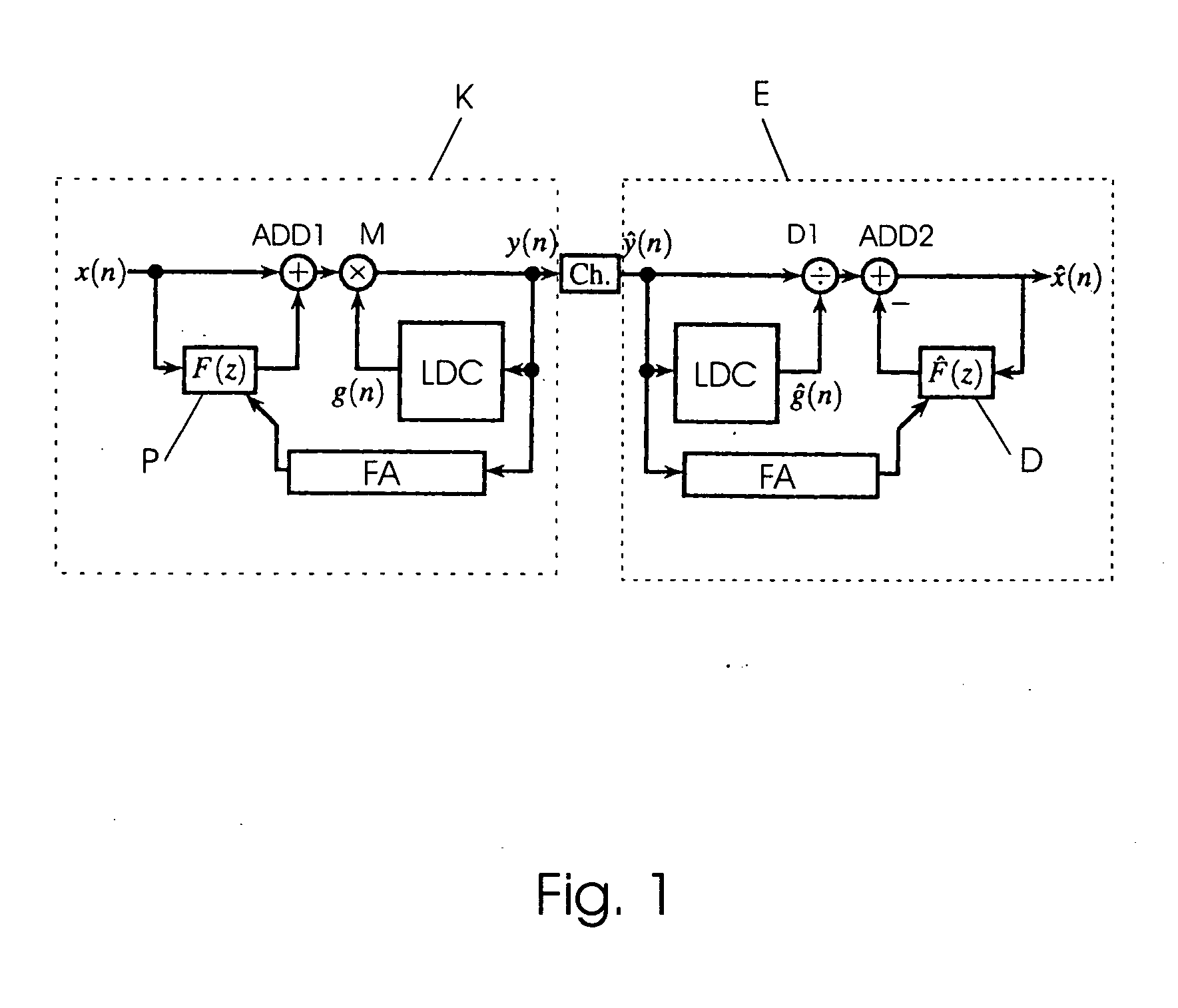

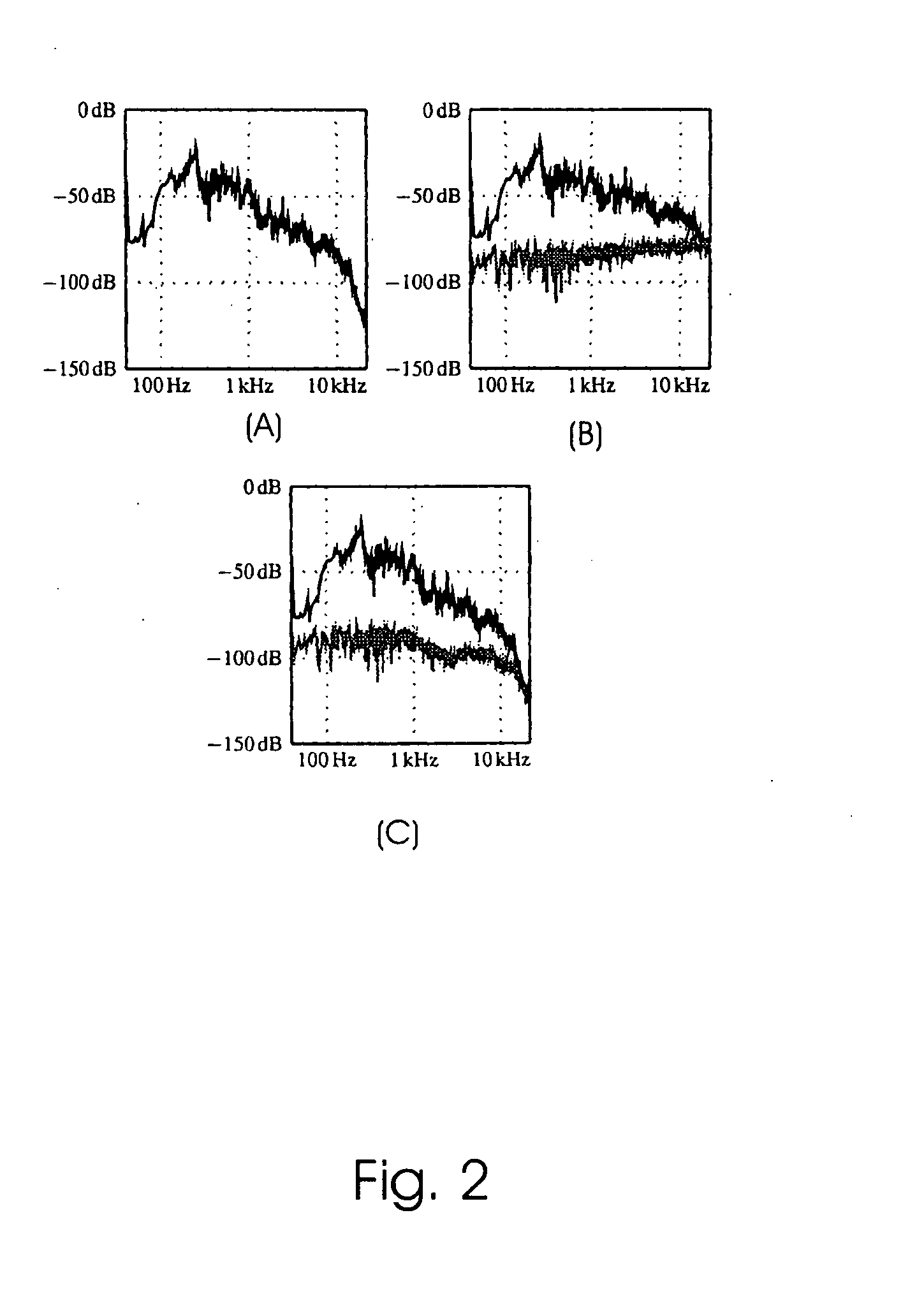

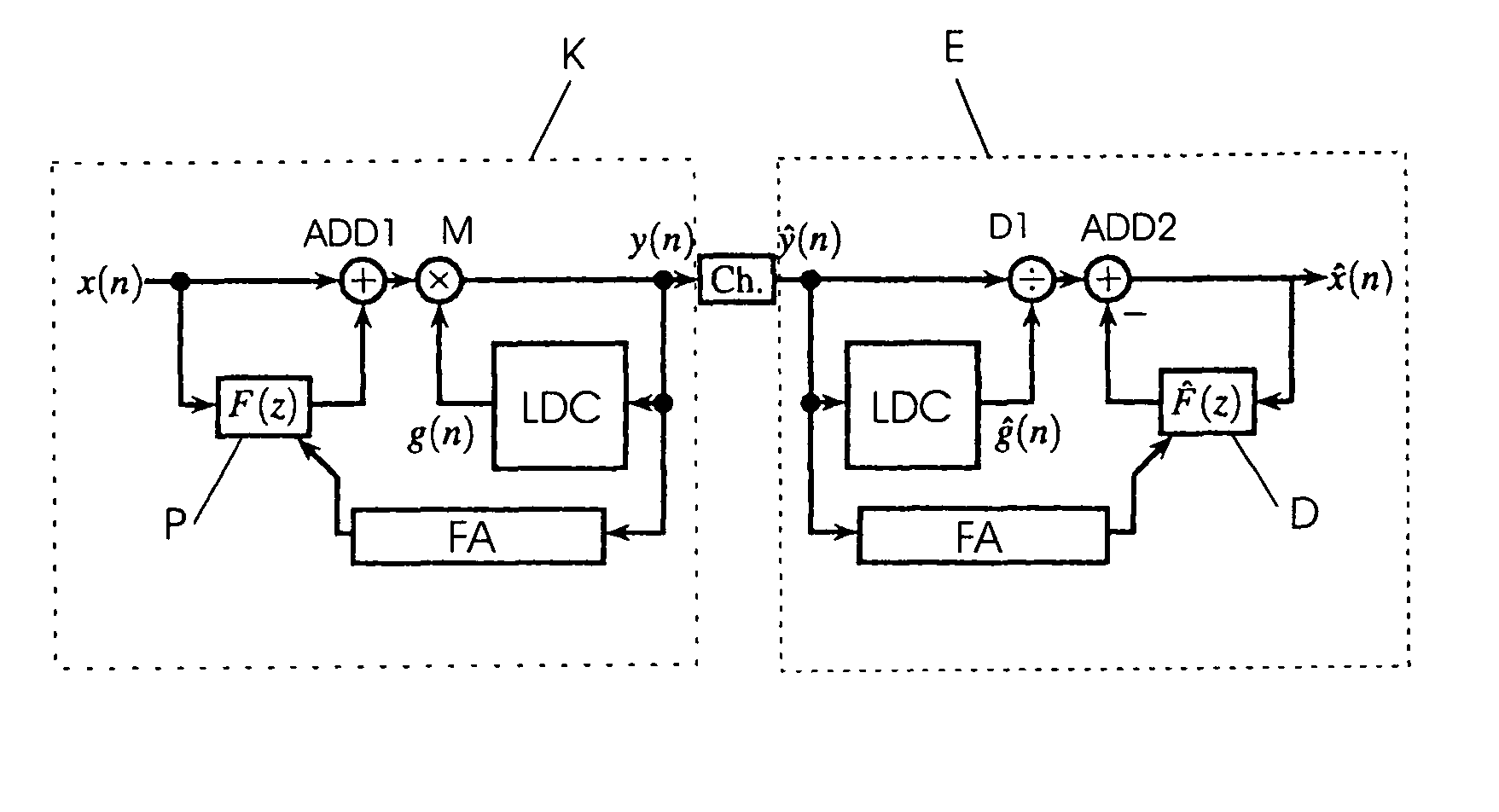

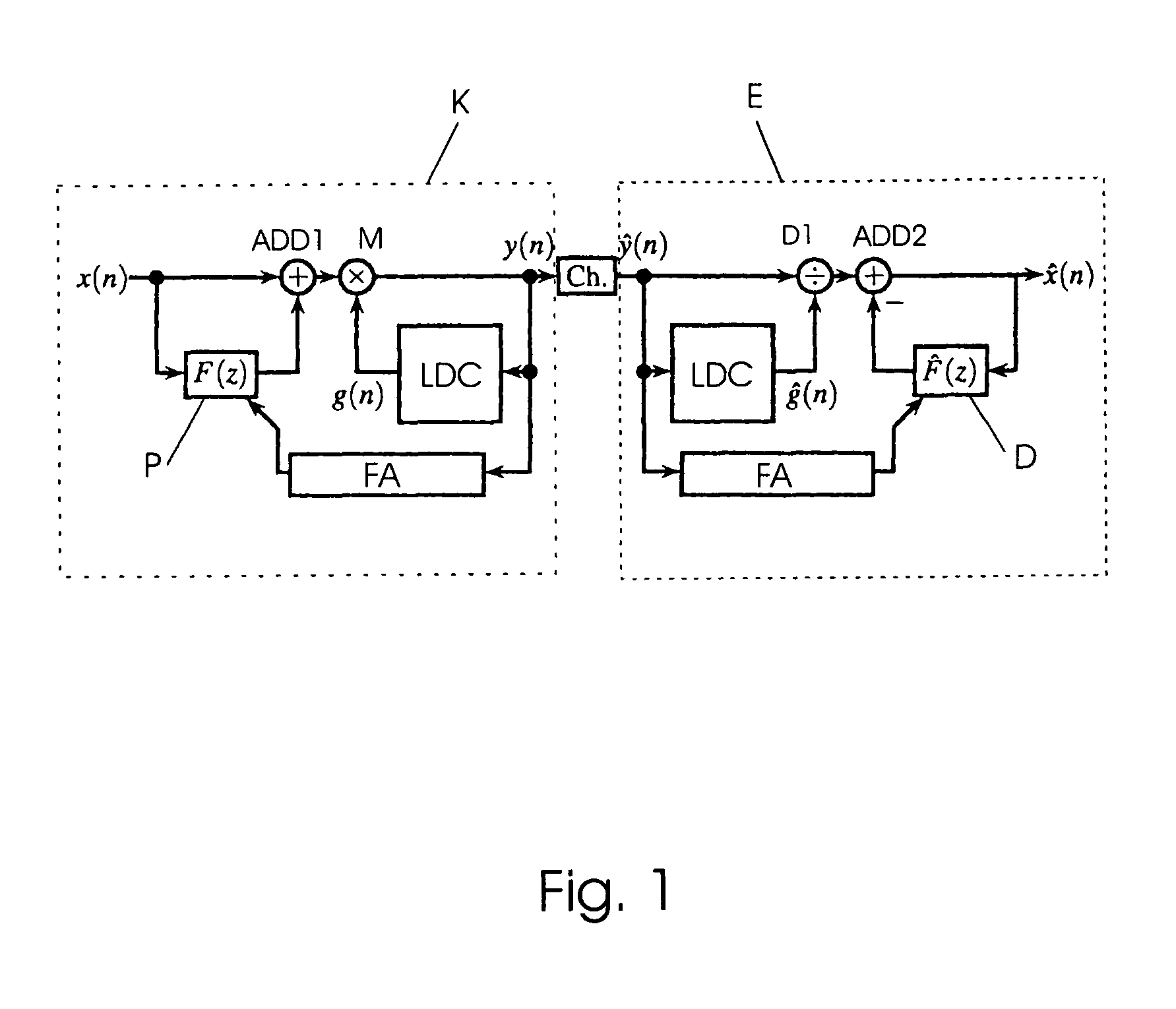

Compander System

ActiveUS20100204995A1Change noiseSpeech analysisVolume compression/expansion in digital/coded amplifiersEngineeringControl equipment

A compressor device for a compander system has a level detecting / control device and a pre-emphasis device for carrying out an adaptive pre-emphasis filtering. The invention is also directed to an expander device for a compander system with a level detecting / control device and a de-emphasis device for carrying out an adaptive de-emphasis filtering.

Owner:SENNHEISER ELECTRONICS GMBH & CO KG

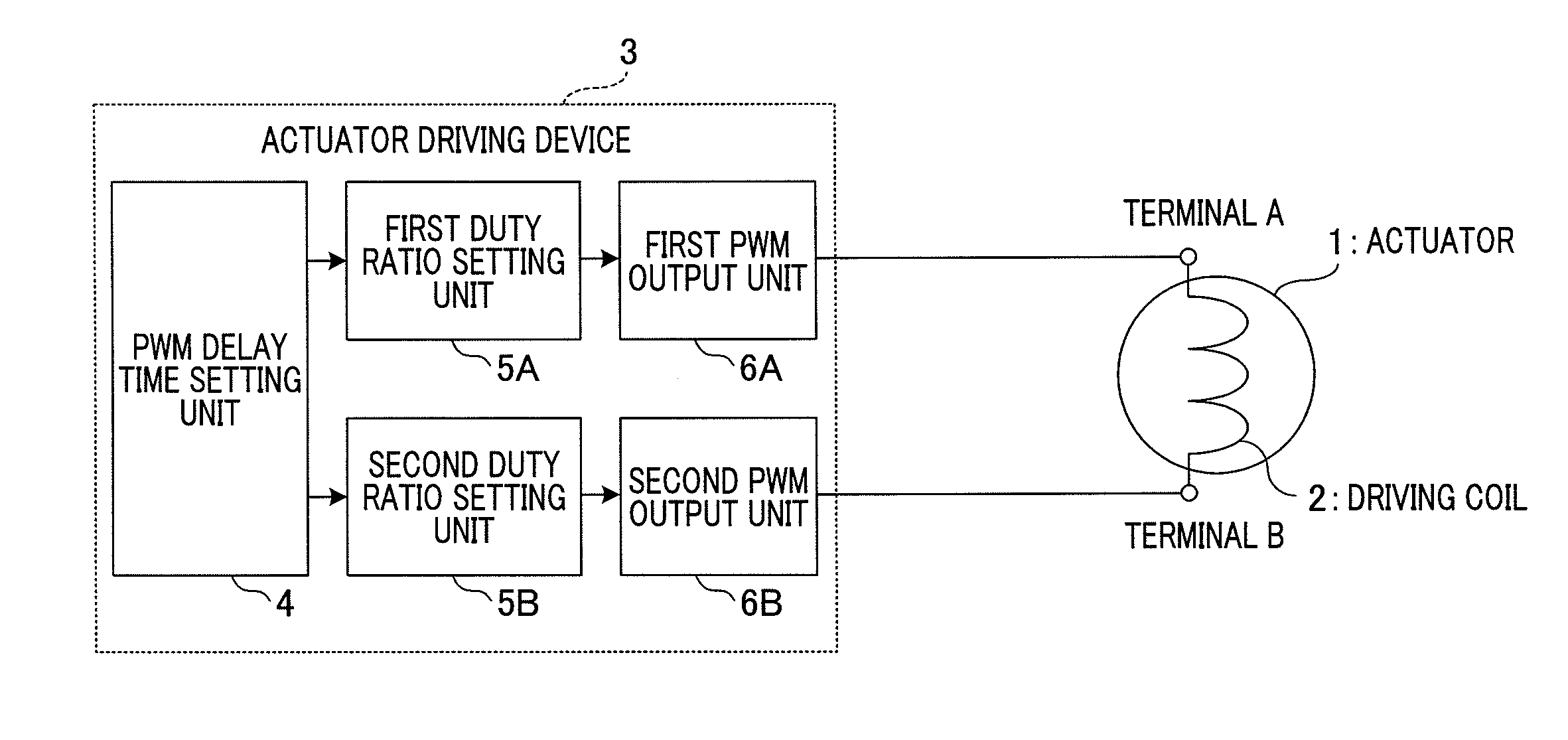

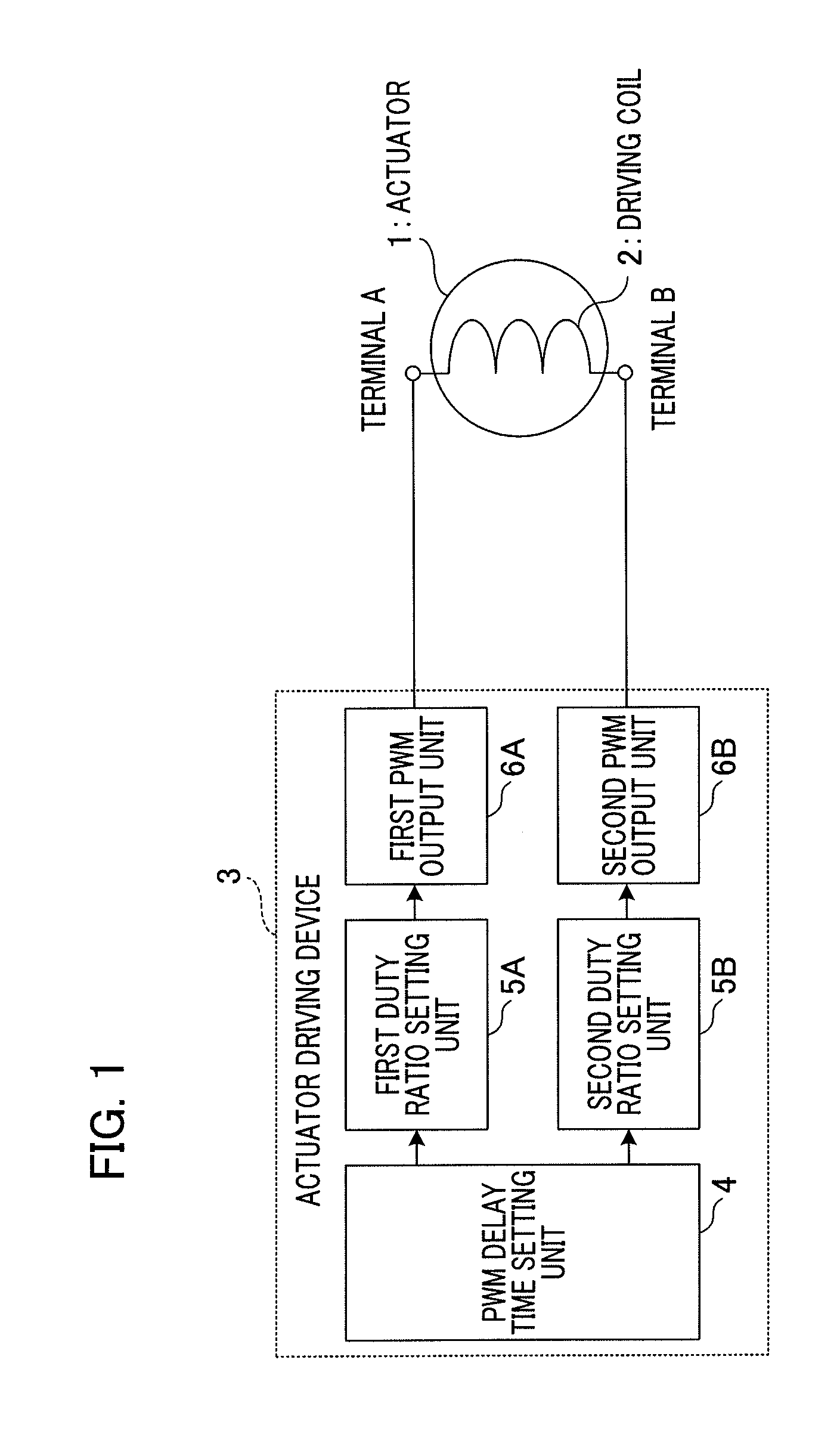

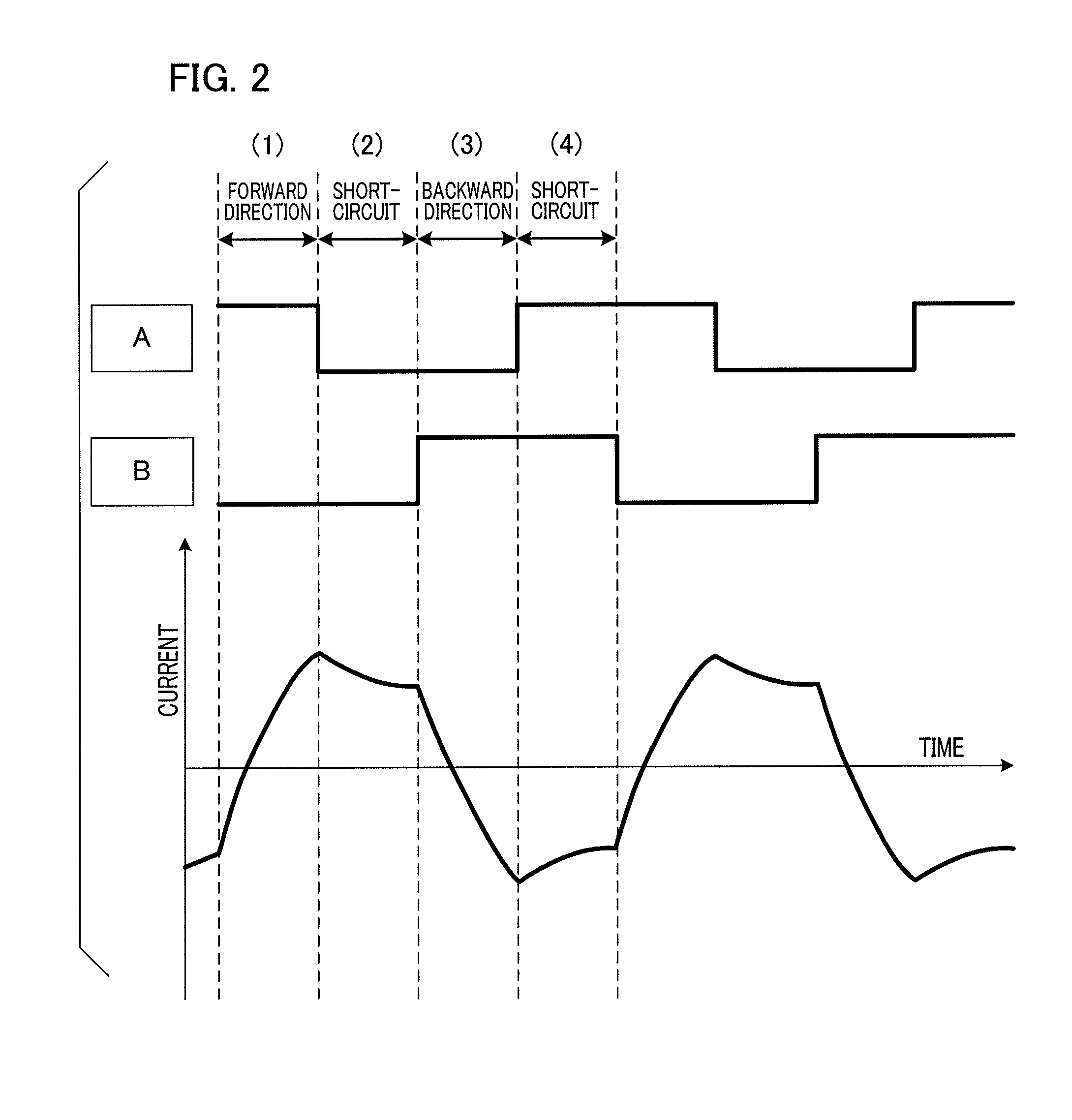

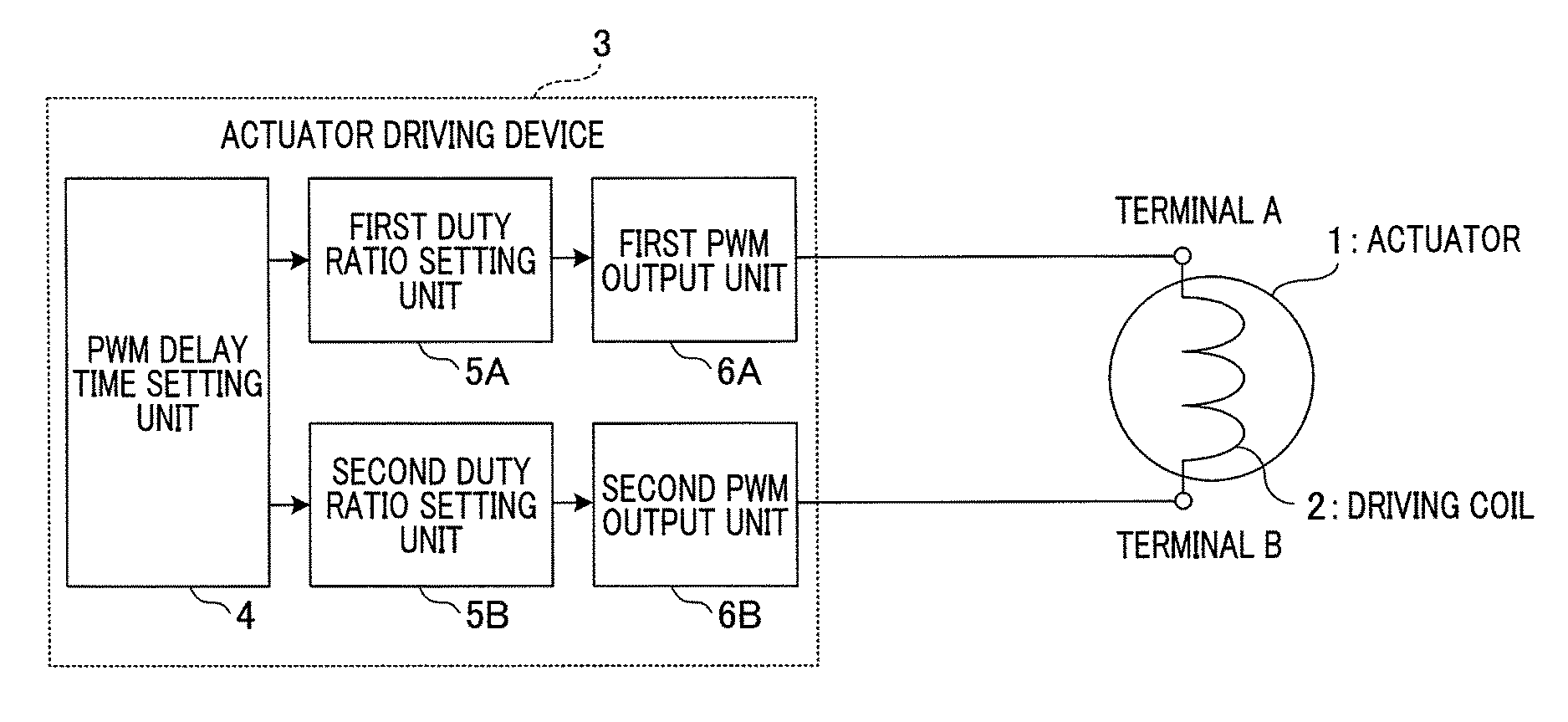

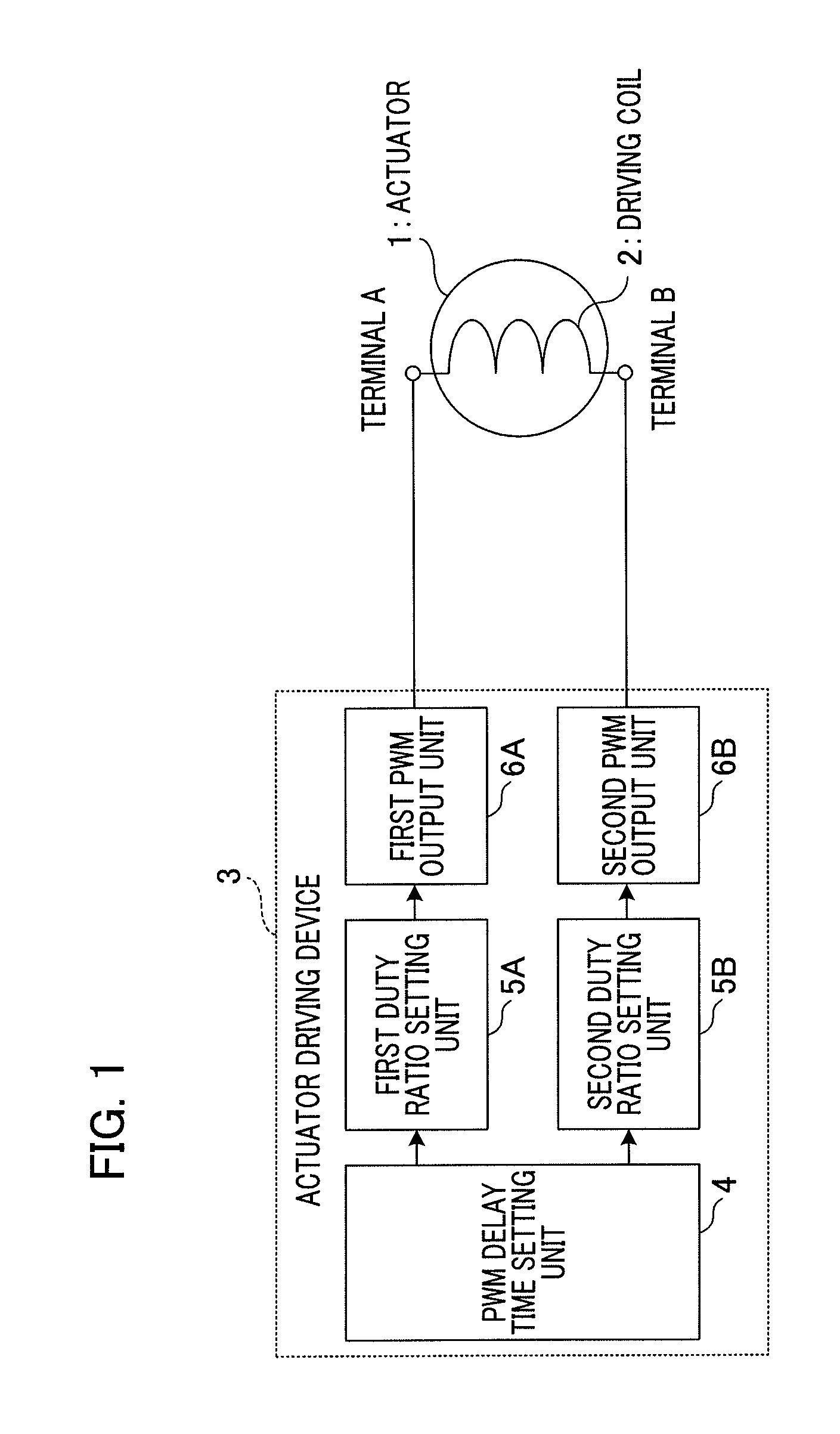

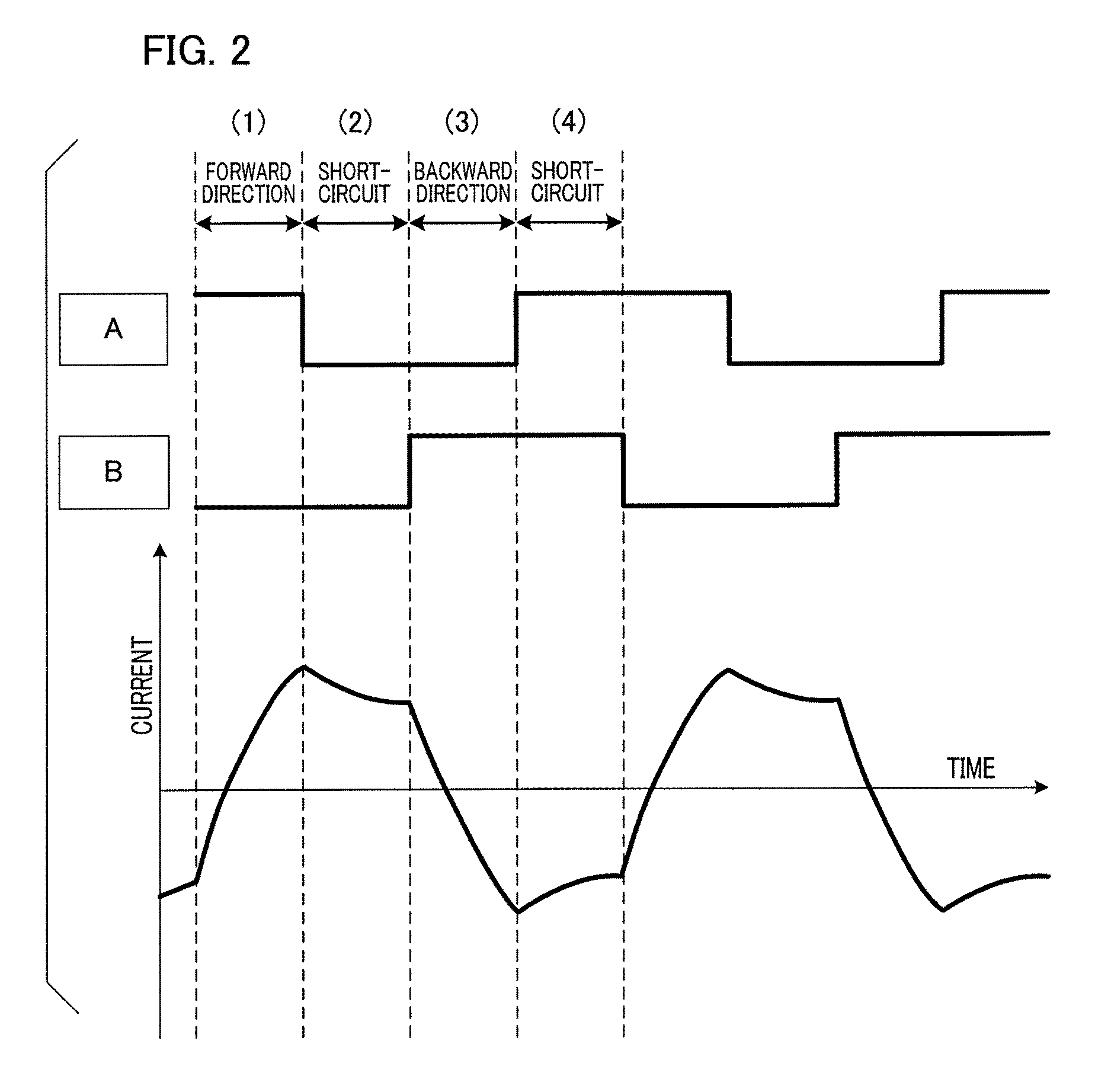

Actuator driving device, control method for same, and imaging apparatus

ActiveUS20140368677A1Reduces magnetic field noiseReduce noiseTelevision system detailsTorque ripple controlPeak valueActuator

An actuator driving device drives an actuator connected to an output terminal. The control unit of the actuator driving device includes a PWM delay time setting unit, a first duty ratio setting unit, and a second duty ratio setting unit. The PWM delay time setting unit sets a delay time of pulse width modulation control for a driving voltage to be applied to the output terminal and outputs setting information to the first and second duty ratio setting units. The first duty ratio setting unit sets the first duty ratio for a first PWM output unit, and the second duty ratio setting unit sets the second duty ratio for a second PWM output unit. When positive and negative energization is performed, the control unit controls to reduce the amount of change in current in the current peak of a PWM waveform by providing a short-circuit period in response to the energization amount.

Owner:CANON KK

Infrared Detection Element, Infrared Detection Module, and Manufacturing Method Therefor

ActiveUS20140284482A1Avoid deformationReduce thicknessLaminationMaterial analysis by optical meansInfraredOptoelectronics

In an infrared detection element 15, a first substrate 36 is bonded to a front side of a pyroelectric substrate 20. Since the thermal expansion coefficient of the first substrate 36 is lower than that of the pyroelectric substrate 20, deformation of the pyroelectric substrate 20 due to thermal expansion can be suppressed by the first substrate 36. Further, since a thermal expansion coefficient difference D is 8.9 ppm / K or less, the thermal expansion coefficient between the first substrate 36 and the pyroelectric substrate 20 is not excessively large, and this can suppress deformation of the infrared detection element 15 due to the thermal expansion coefficient difference between the first substrate 36 and the pyroelectric substrate 20.

Owner:NGK INSULATORS LTD

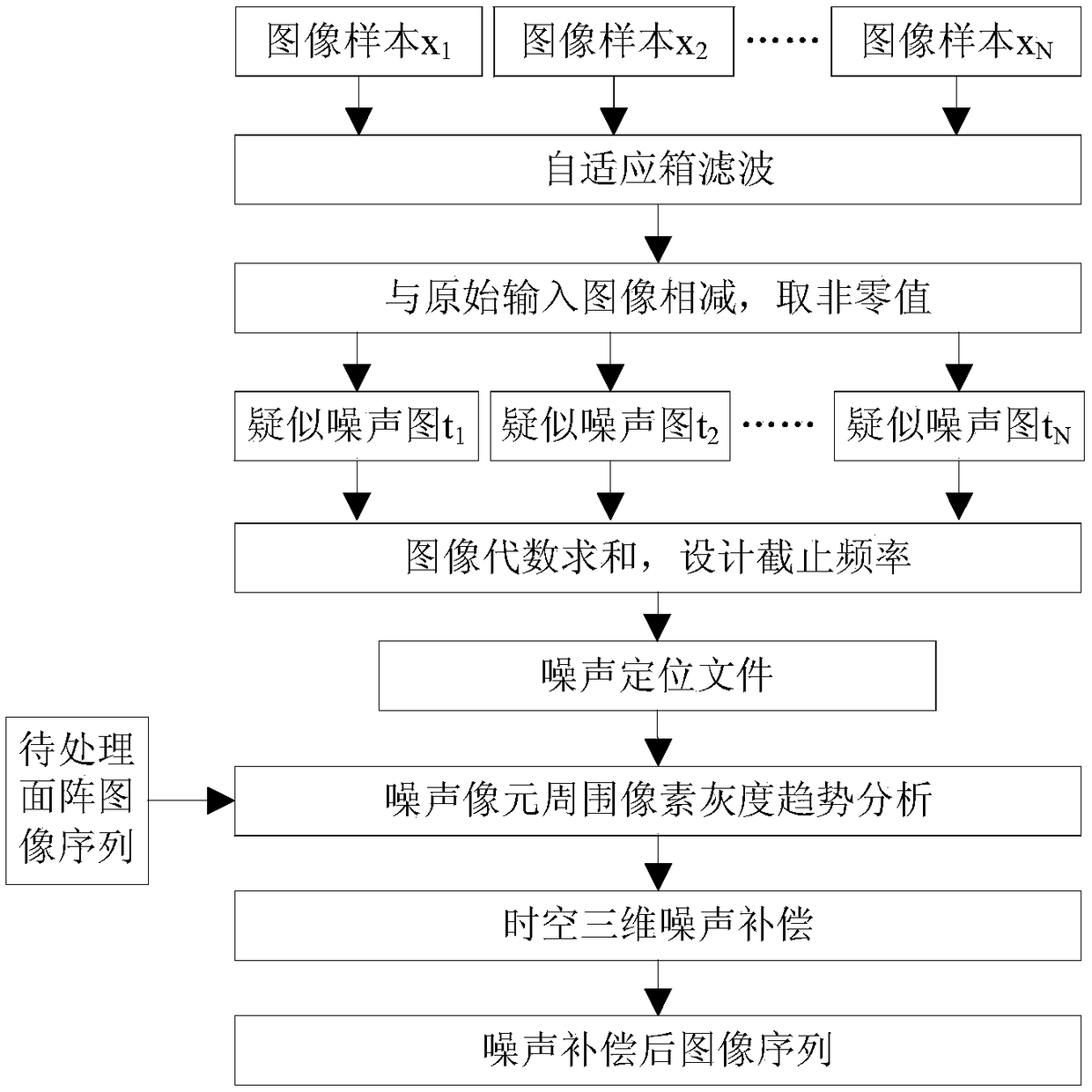

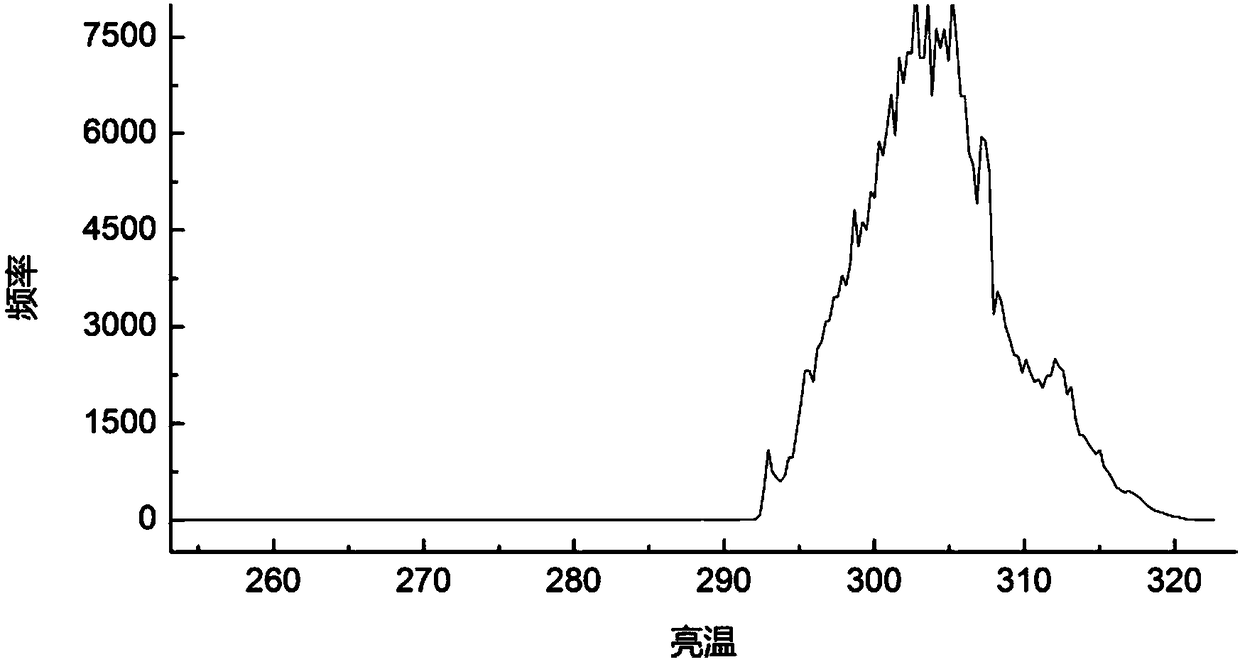

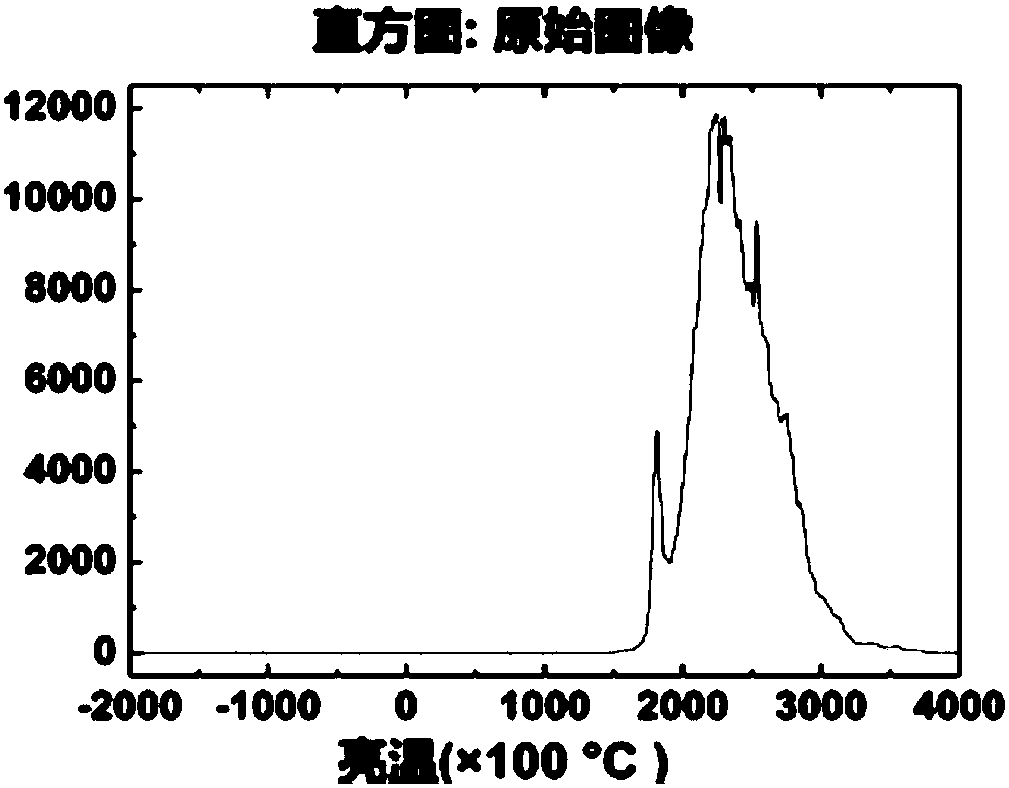

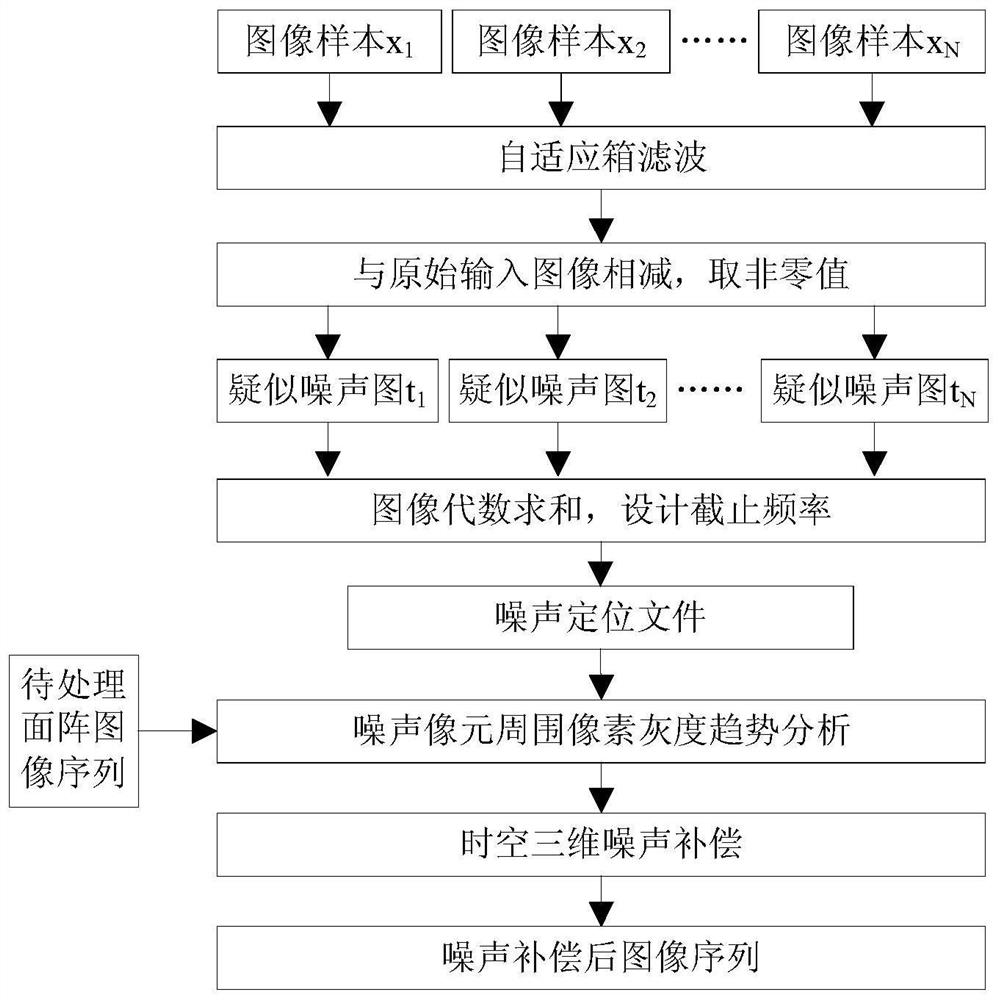

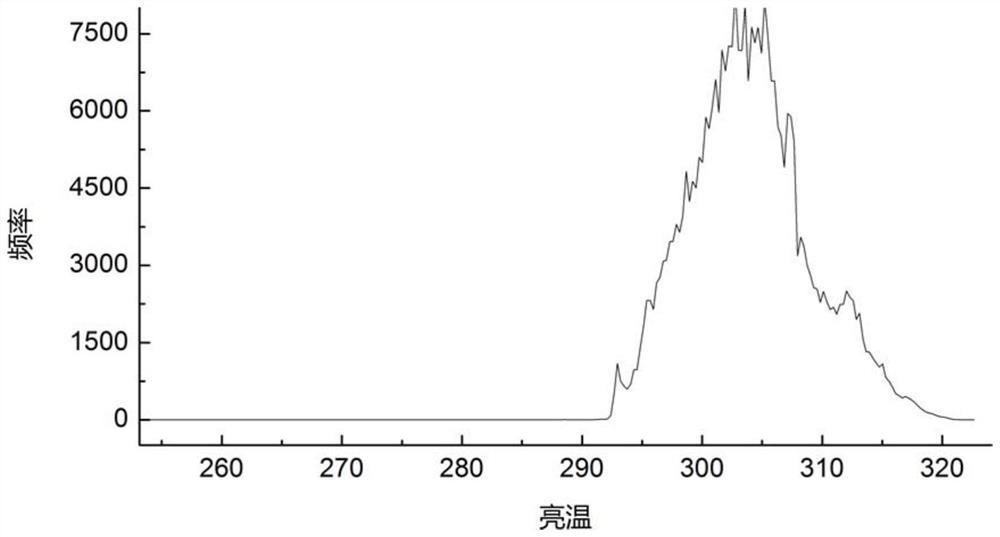

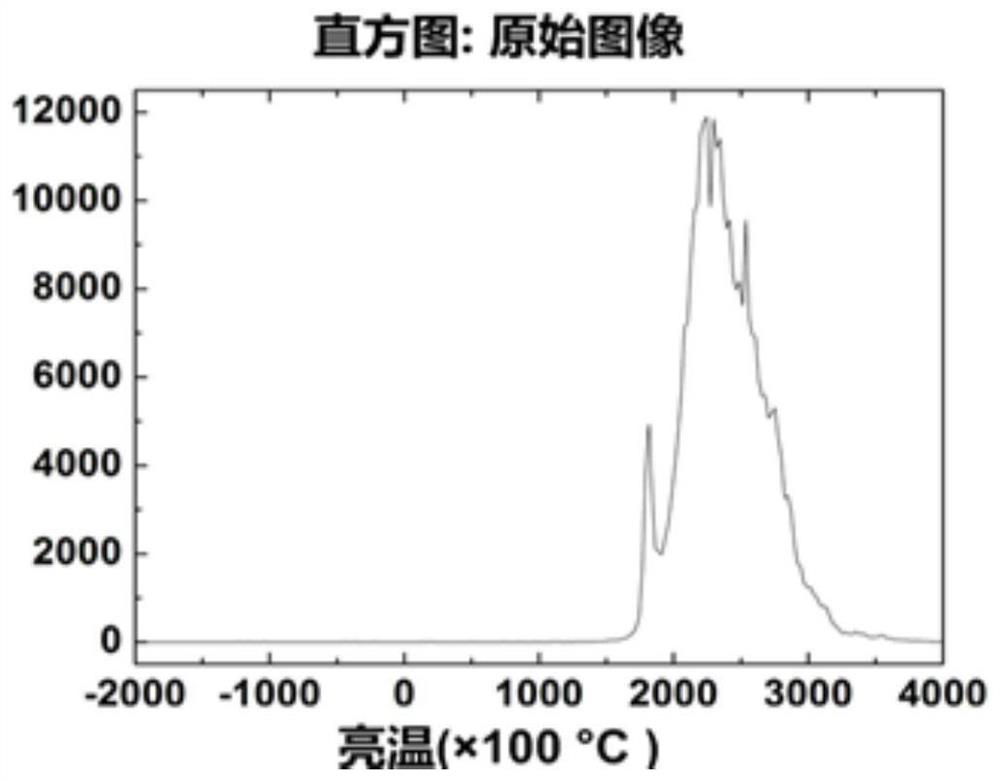

Area-array gazed infrared remote-sensing-image space-time three-dimensional noise identification and compensation method

ActiveCN108470325AReduce typing errorsRapid positioningImage enhancementImage analysisInfrared remote sensingOrbit

The invention provides an area-array gazed infrared remote-sensing-image space-time three-dimensional noise identification and compensation method. In the method, aiming at an unstable three-dimensional noise generated by row, column and time axes in an area-array gazed infrared image, accurate noise positioning and compensation processing are realized. The method is realized by five processes ofsample selection, spatial filtering, noise primary selection, noise positioning file making and noise compensation. The method has characteristics that the method does not rely on blackbody calibration information, noise positioning is accurate, noise pixels are only processed and image information is not lost. When an existing noise filtering method is applied to an area-array infrared remote-sensing image sequence possessing the space-time three-dimensional unstable noise, a calculated amount is large, the image information is easy to lose and so on. In the invention, the above disadvantagesare overcome; the method can be applied to the on-orbit processing of an infrared image, quality improvement and other fields; and area-array infrared-image geometric matching accuracy can be increased.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

Compander which uses adaptive pre-emphasis filtering on the basis of linear prediction

ActiveUS8190427B2Change noiseSpeech analysisVolume compression/expansion in digital/coded amplifiersEngineeringLinearity

Owner:SENNHEISER ELECTRONICS GMBH & CO KG

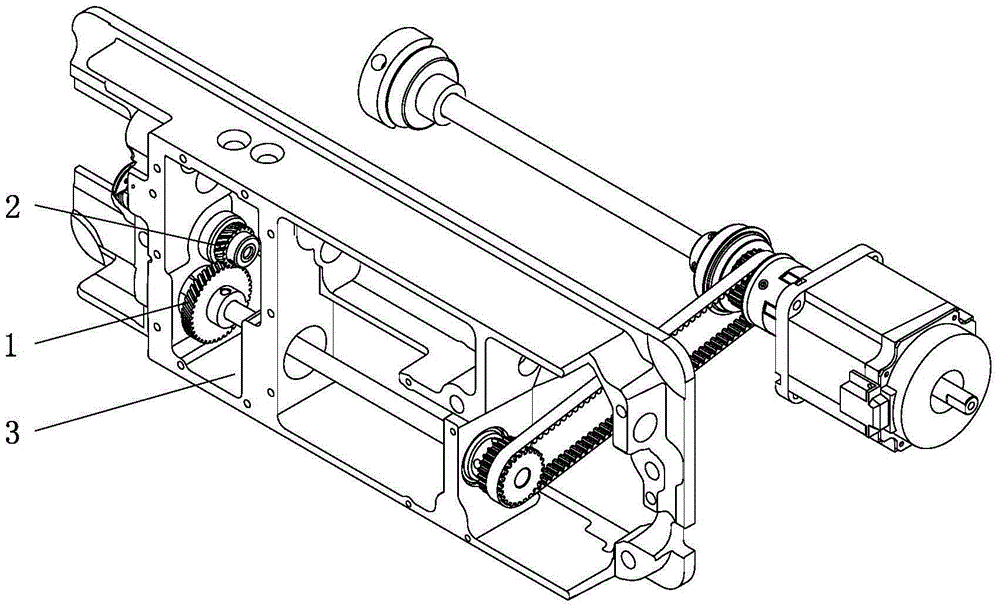

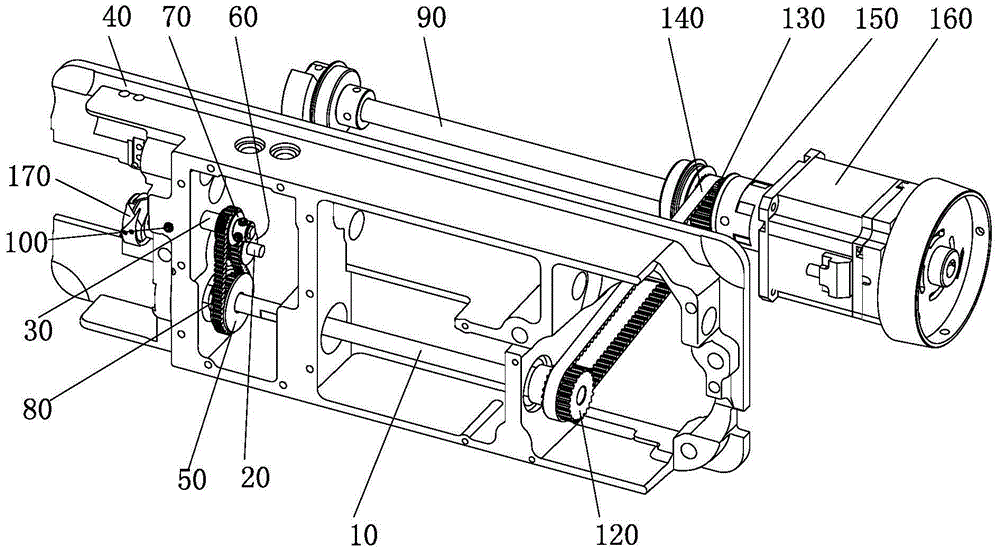

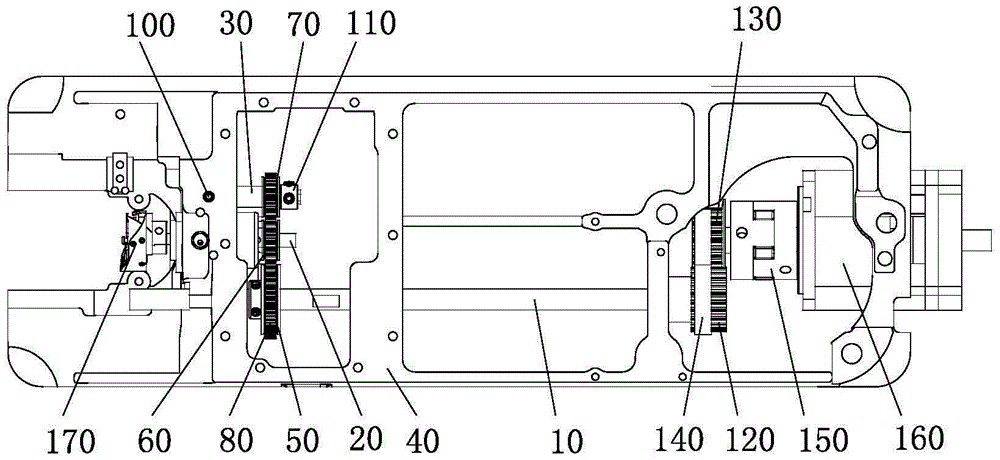

Linear-driven multi-freedom-degree mechanical arm joint based on smart material

The invention provides a linear-driven multi-freedom-degree mechanical arm joint based on a smart material. Under the excitation of signals, a moving sliding block is pulled by an SMA driving wire to drive a split fork to move so as to pull a joint connecting frame to rotate, and the joint connecting frame is made to swing around the perpendicular plane with a shoulder end brace as a center. At a fore joint driving position, a moving sliding block is pulled by an SMA driving wire to pull a split fork to rotate, and a joint connecting frame is driven to swing around the horizontal plane with a shaft hole of the perpendicular plate side of the joint connecting frame as a center. At two fore joint driving positions, an SAM driving wire on a joint connecting frame drives a moving sliding block to drive the split fork to rotate around an outer side shaft hole of the joint connecting frame so as to drive an axial joint connecting frame to rotate in the axis direction, and the multi-freedom-degree movement of the mechanical arm joint is achieved finally. According to the linear-driven multi-freedom-degree mechanical arm joint based on the smart material, due to the fact that the SMA wires are adopted, the linear output of power driving can be achieved directly, and the defects of energy consumption and noise caused by using a middle mechanism in the axial driving of a traditional motor are overcome.

Owner:HARBIN ENG UNIV

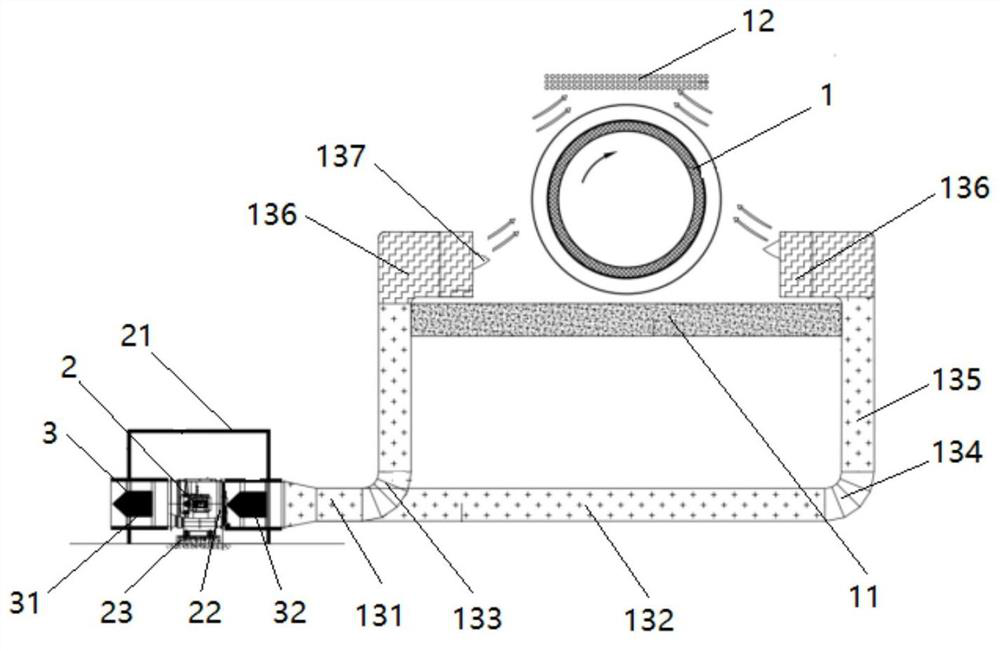

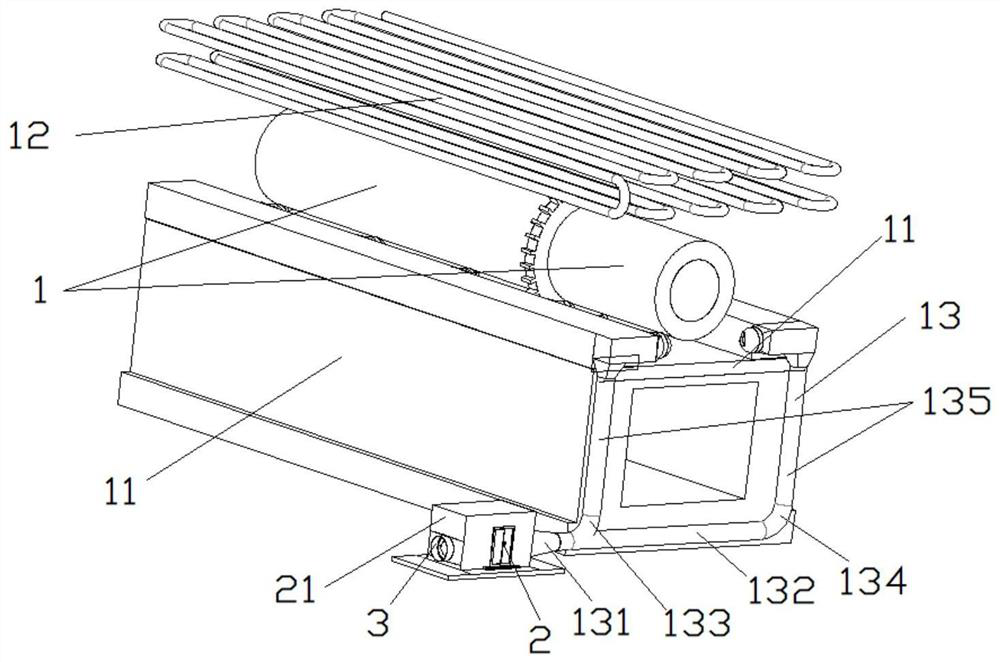

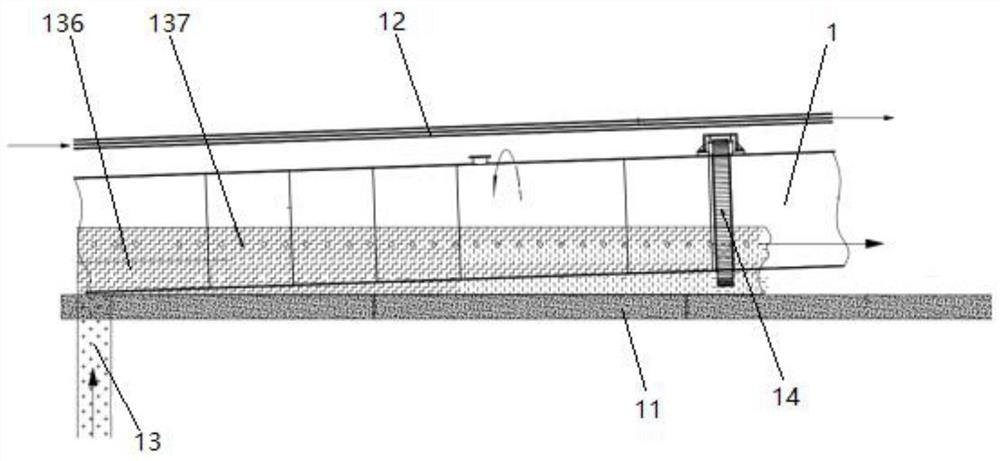

Cement rotary kiln comprehensive noise reduction and heat recovery system

PendingCN114111326AImprove efficiencyCancel noisePump componentsRotary drum furnacesThermal pollutionNoise elimination

The invention discloses a comprehensive noise reduction and heat recovery system for a cement rotary kiln. The comprehensive noise reduction and heat recovery system comprises a rotary kiln platform arranged at the bottom of the rotary kiln, a cooling coil arranged at the top of the rotary kiln, air pipe air supply units arranged at the two ends of the rotary kiln platform, fans arranged at the input ends of the air pipe air supply units and noise elimination mechanisms arranged on the fans. A fan shock absorber is arranged below the fan; the draught fan is covered with a draught fan sound insulation cover. The silencing mechanism comprises a fan inlet silencer and a fan outlet silencer, and fan noise is jointly reduced through the fan inlet silencer, the fan outlet silencer, a fan sound insulation cover and a fan shock absorber; cooling air from the air pipe air supply unit is changed into hot air after cooling the rotary kiln, the cooling coil recovers heat from the hot air and heat radiation of the rotary kiln, then the rotary kiln body is cooled and waste heat is recovered in the rotary kiln production process of the cement plant, noise reduction and heat recovery are comprehensively considered, the noise reduction effect is guaranteed, heat recovery is increased, and the production efficiency is improved. And carbon emission and thermal pollution are reduced.

Owner:宁波源海博创科技有限公司

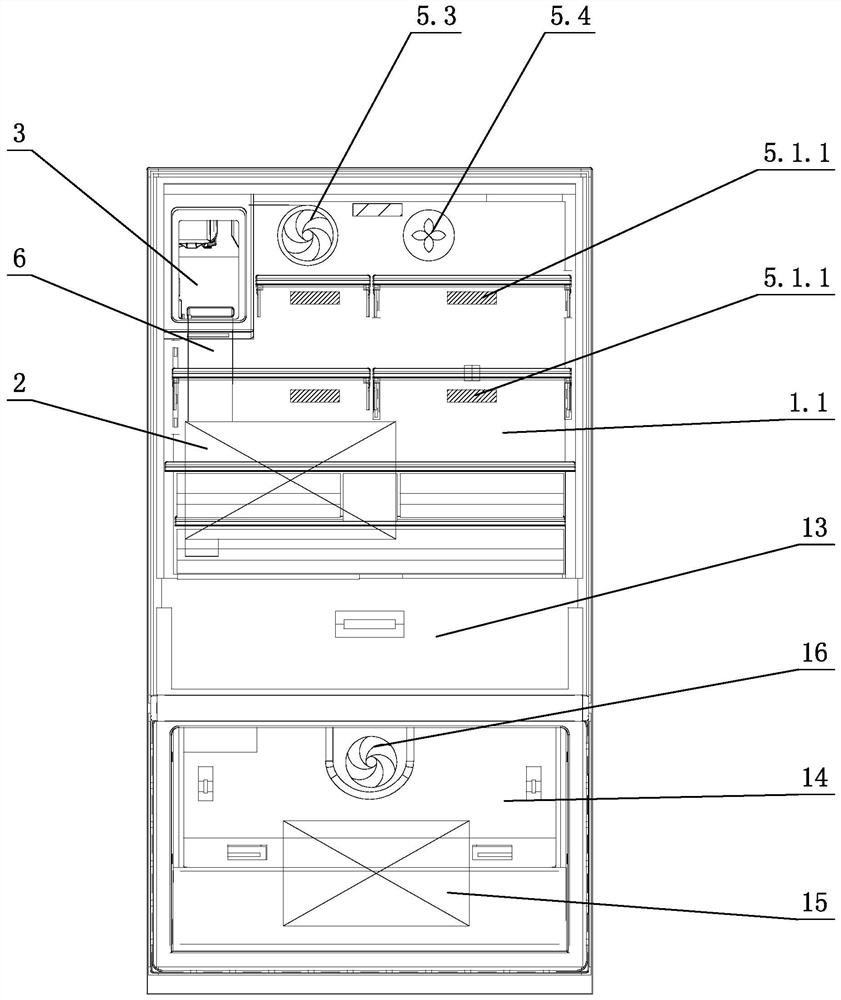

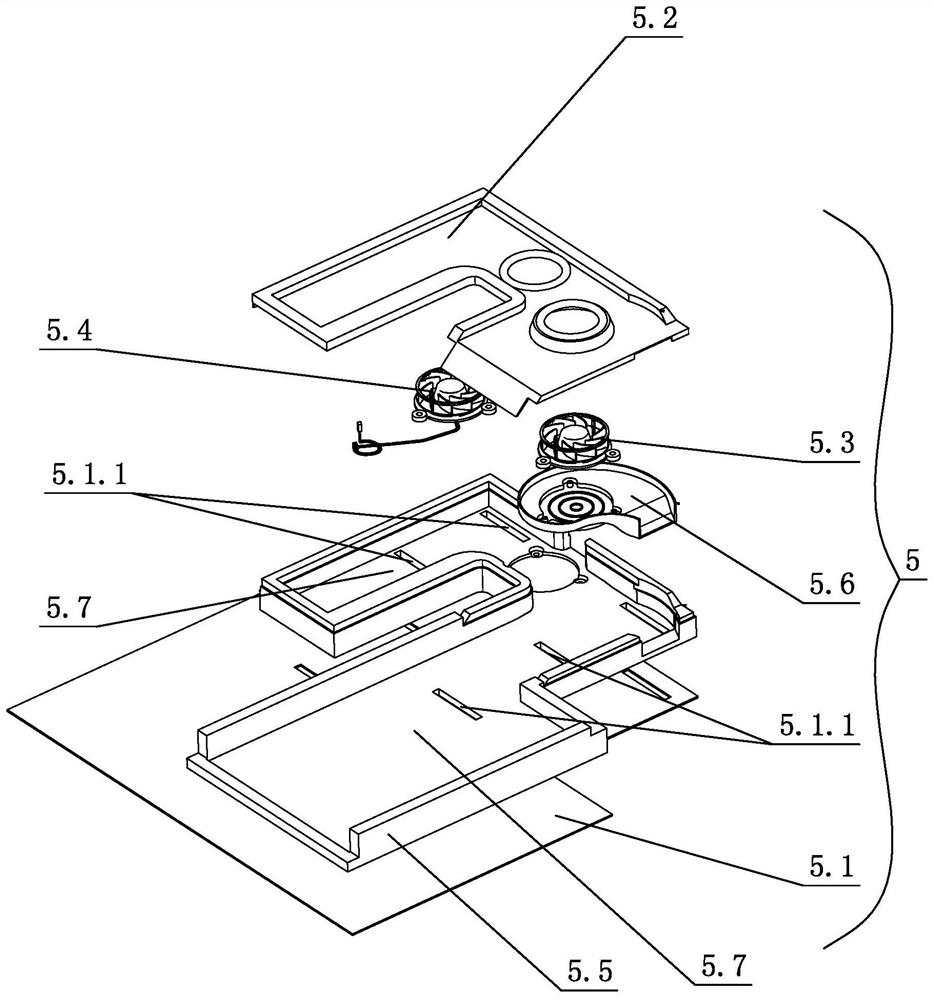

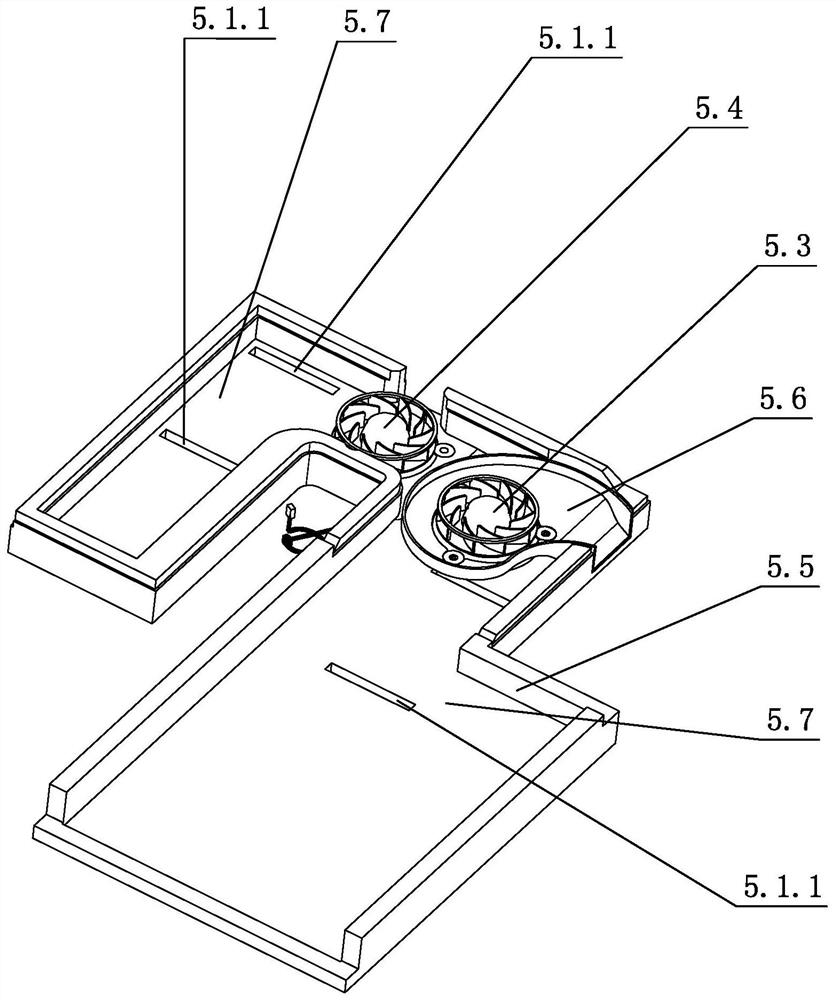

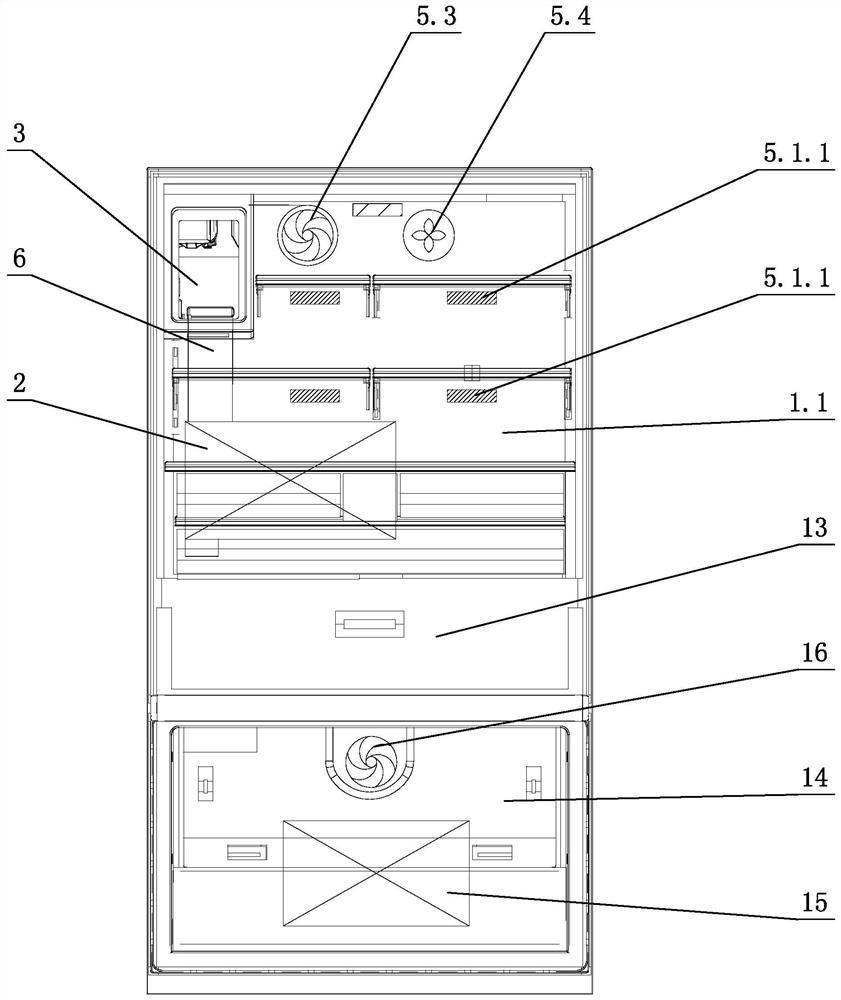

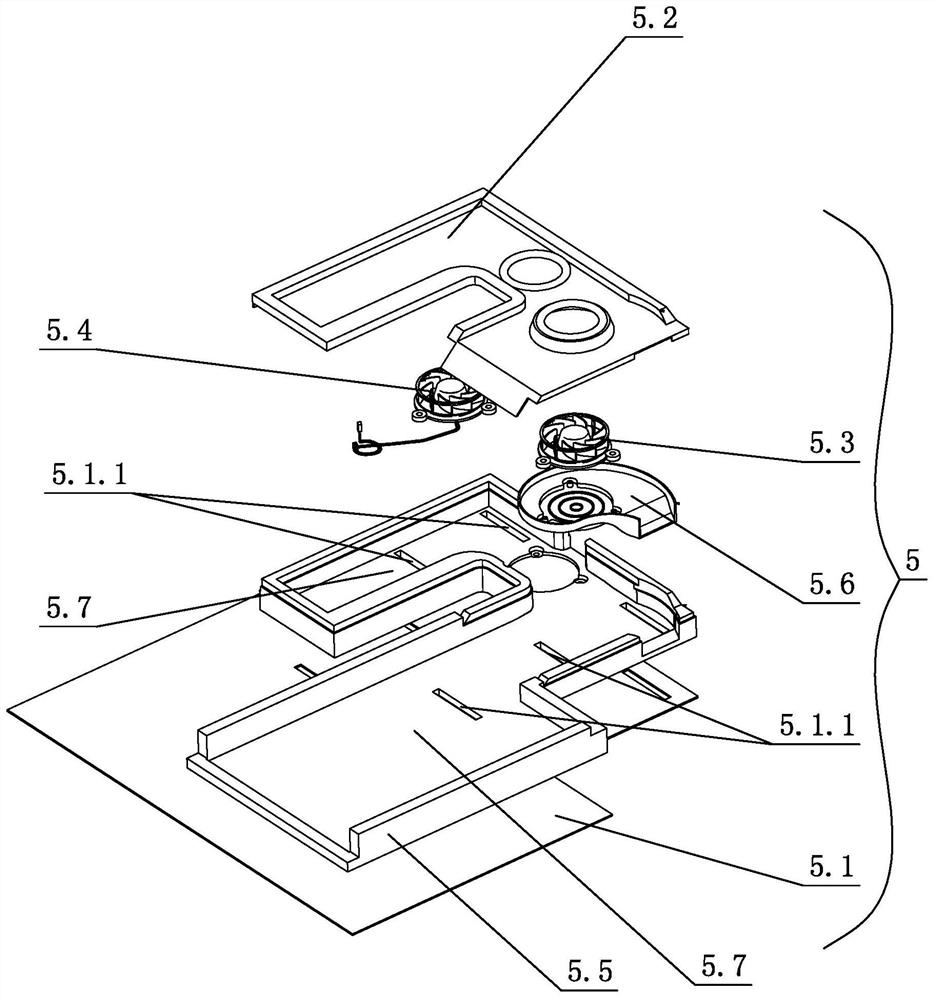

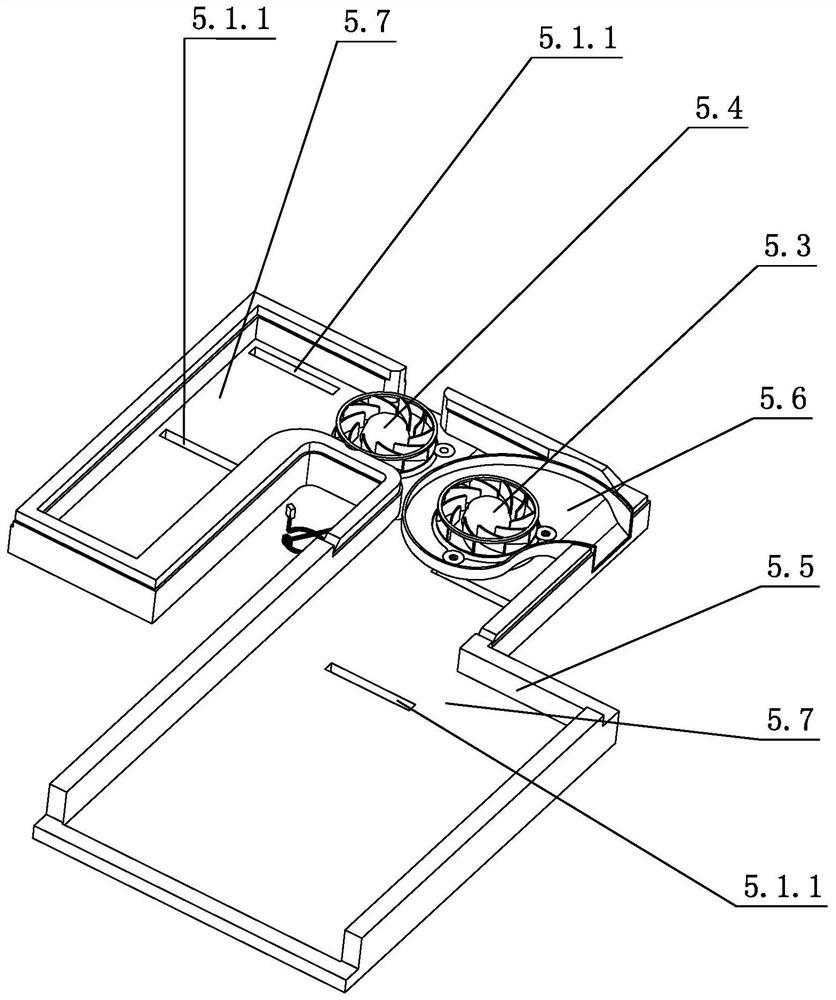

Refrigerating system of refrigerator

ActiveCN111829259AReduce in quantitySimple refrigeration structureLighting and heating apparatusDomestic refrigeratorsCold airThermodynamics

The invention discloses a refrigerating system of a refrigerator. The refrigerator comprises a refrigerating chamber inner container, a refrigerating chamber and a refrigerating chamber evaporator; anice-making assembly is arranged on the refrigerating chamber inner container and comprises an ice-making chamber and an ice-making machine; the refrigerating chamber inner container is provided withan air duct assembly, a cold air duct communicating with the refrigerating chamber evaporator is formed between the inner side of the refrigerating chamber inner container and the outer side of the air duct assembly, and the air duct assembly comprises an ice-making air duct and a refrigerating air duct; a refrigerating fan for supplying air to the refrigerating chamber is arranged in the refrigerating air duct, and the refrigerating fan discharges cold air to the refrigerating chamber from an air outlet; an ice-making fan for supplying air to the ice-making chamber is arranged in the ice-making air duct, and the ice-making fan discharges cold air to the ice-making chamber through an air supply pipeline; and the ice-making chamber and the refrigerating chamber share one refrigerating chamber evaporator and one cold air duct, the refrigerating air duct and the ice-making air duct are integrally formed, or the ice-making air duct is arranged in the refrigerating air duct. According to the system, the ice-making chamber and the refrigerating chamber share one refrigerating chamber evaporator, so that the number of refrigerator evaporators is reduced, the cost is reduced, the internalvolume of the refrigerator is increased, and a refrigerating structure of the refrigerator is simplified.

Owner:GUANGDONG GALANZ GRP CO LTD +1

High-power high-frequency reactor

PendingCN109841374AReduce Flux LeakageReduce the number of turnsTransformers/inductances casingsTransformers/inductances coils/windings/connectionsMagnetic coreFastener

The invention discloses a high-power high-frequency reactor comprising a reactor body, the reactor body is composed of a magnetic core and a coil, the middle of the magnetic core is provided with thecoil, both the coil and the magnetic core are made of copper materials, the reactor body is a shell structure, the inner part of the shell structure is set in a centering type, the shell structure isformed by a block splicing group and ring stacked columns, magnetic path between rings of the block splicing group is independent without other artificial gaps, and the computability of the electromagnetic theory is good. The fixation of rings with glue is not needed, the coil and the ring-shaped magnetic core support each other and fix each other, and the adding of a special fastener for the magnetic core and the coil is not needed. The structure of the high-power high-frequency reactor is a shell structure, the centering type (block splicing group and ring stacked column type) has small magnetic leakage, the number of turns can be reduced in a product with the same inductance, the DC overlap characteristic is good, the amount of copper is reduced, the material cost is low, the product structure and process are simple, the high-power high-frequency reactor is easy to produce, and the labor cost is low.

Owner:JIANGSU JIANLI ELECTRONICS TECH

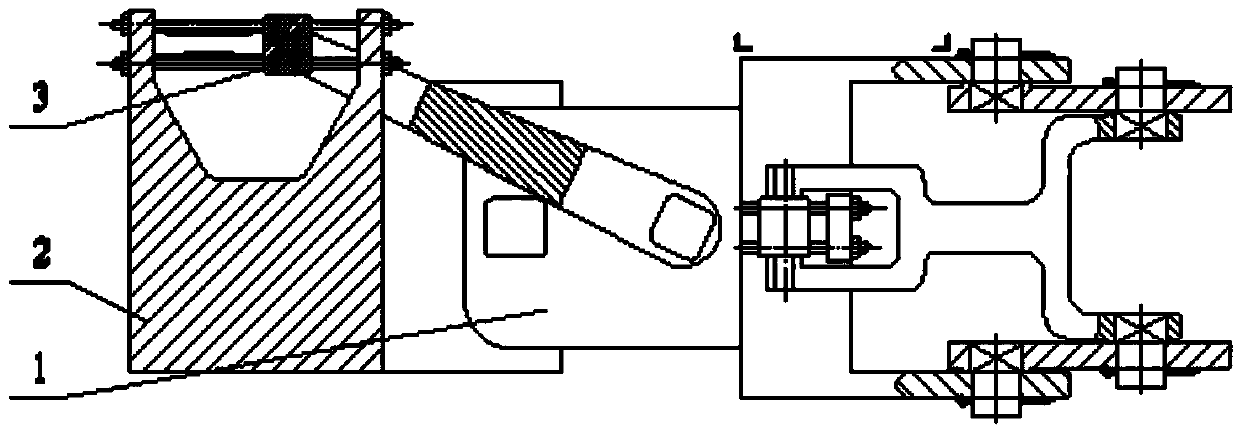

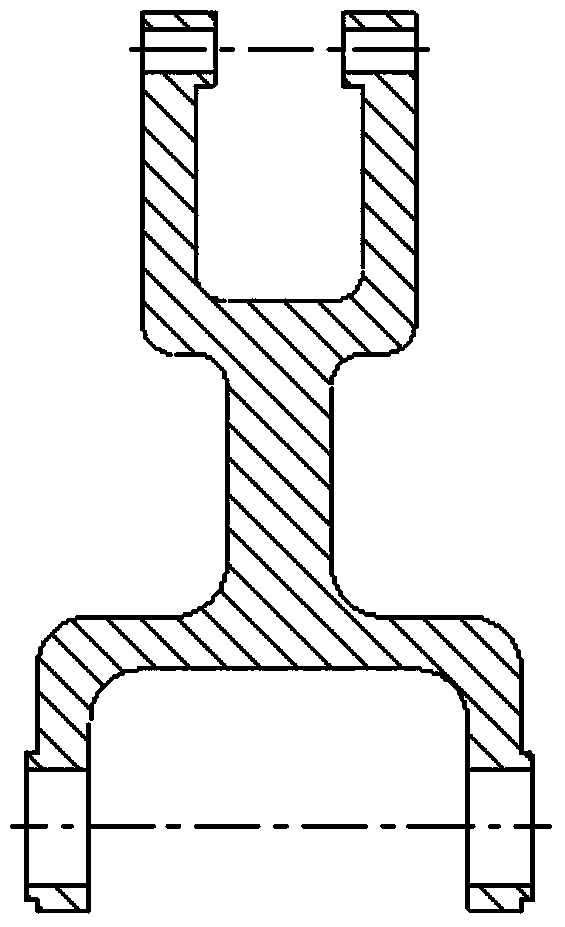

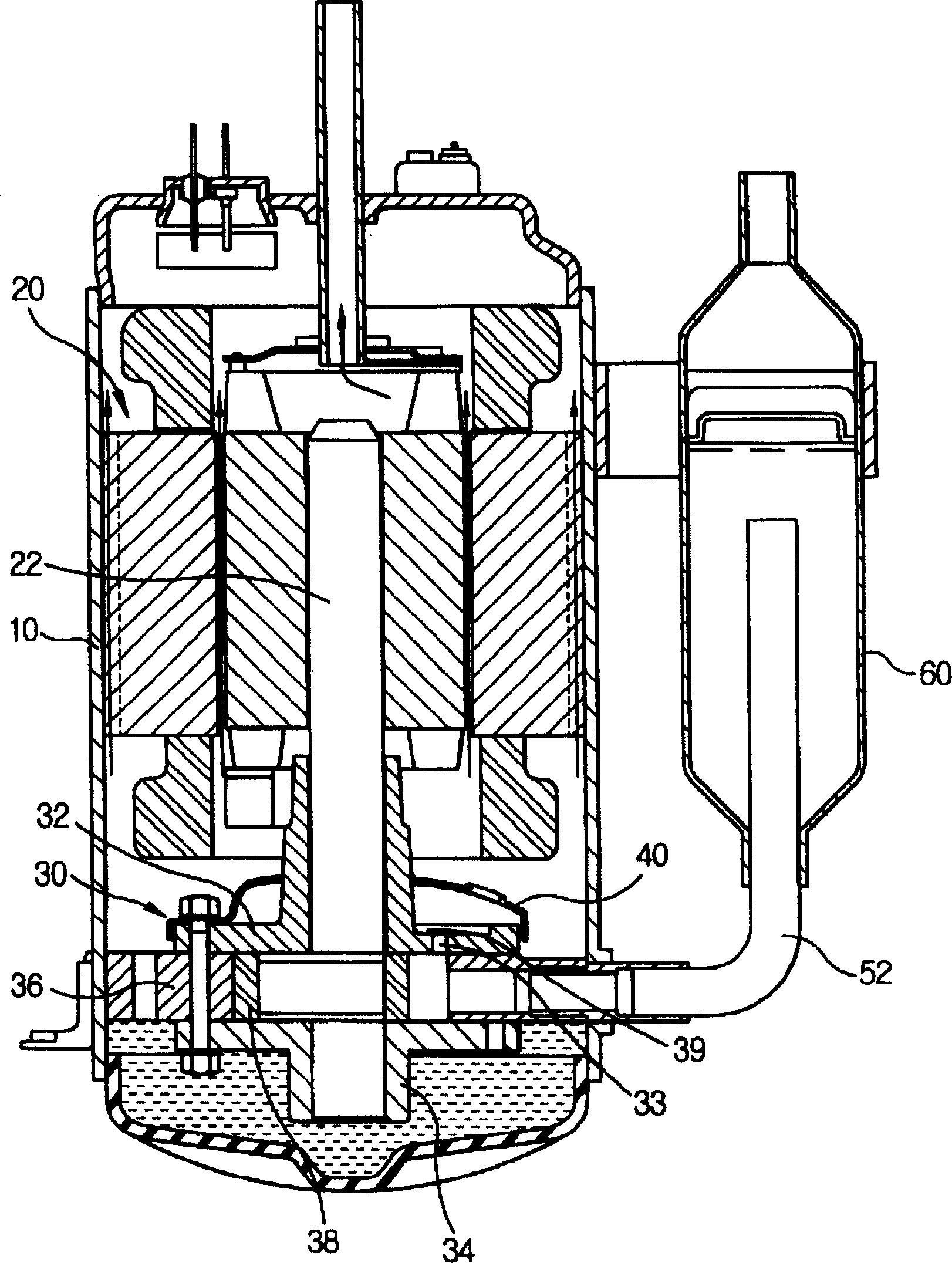

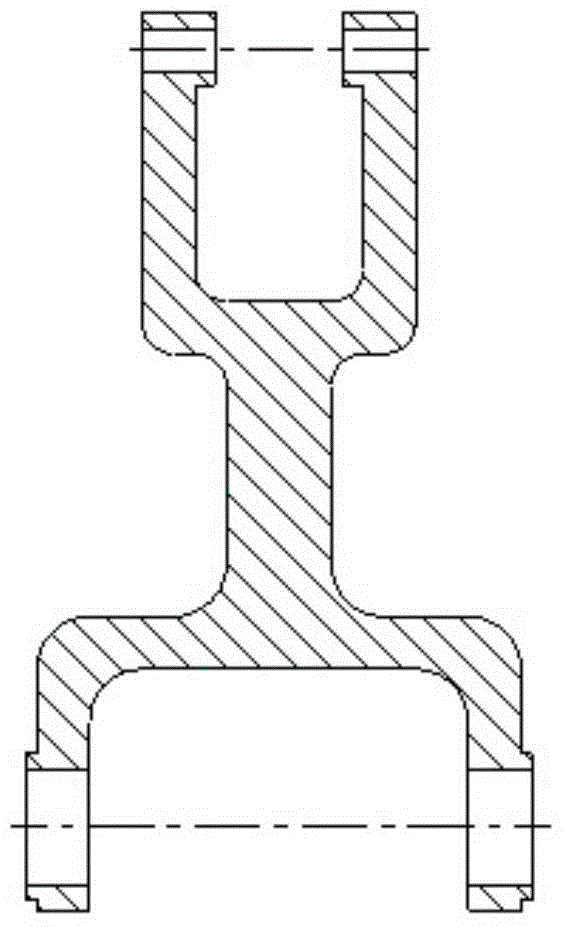

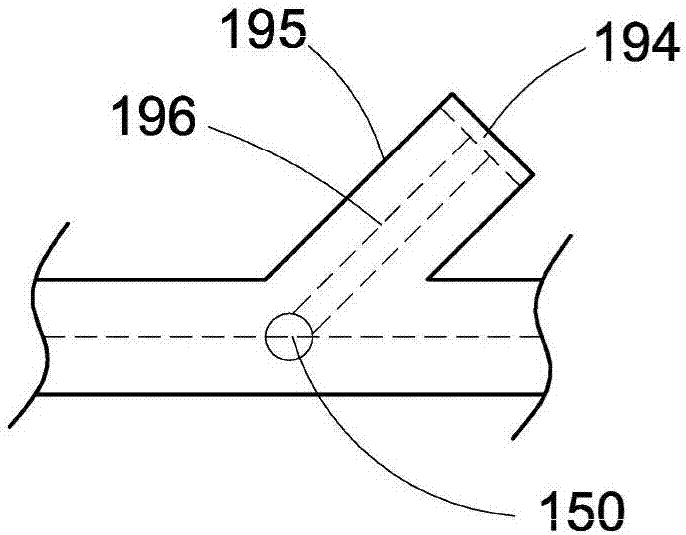

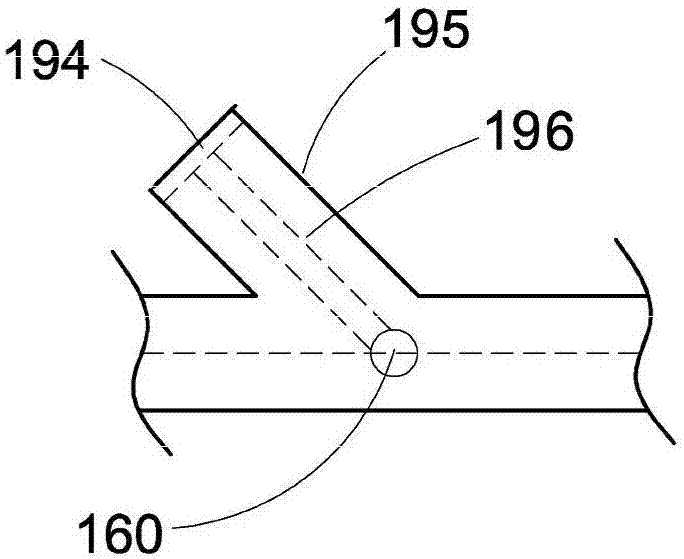

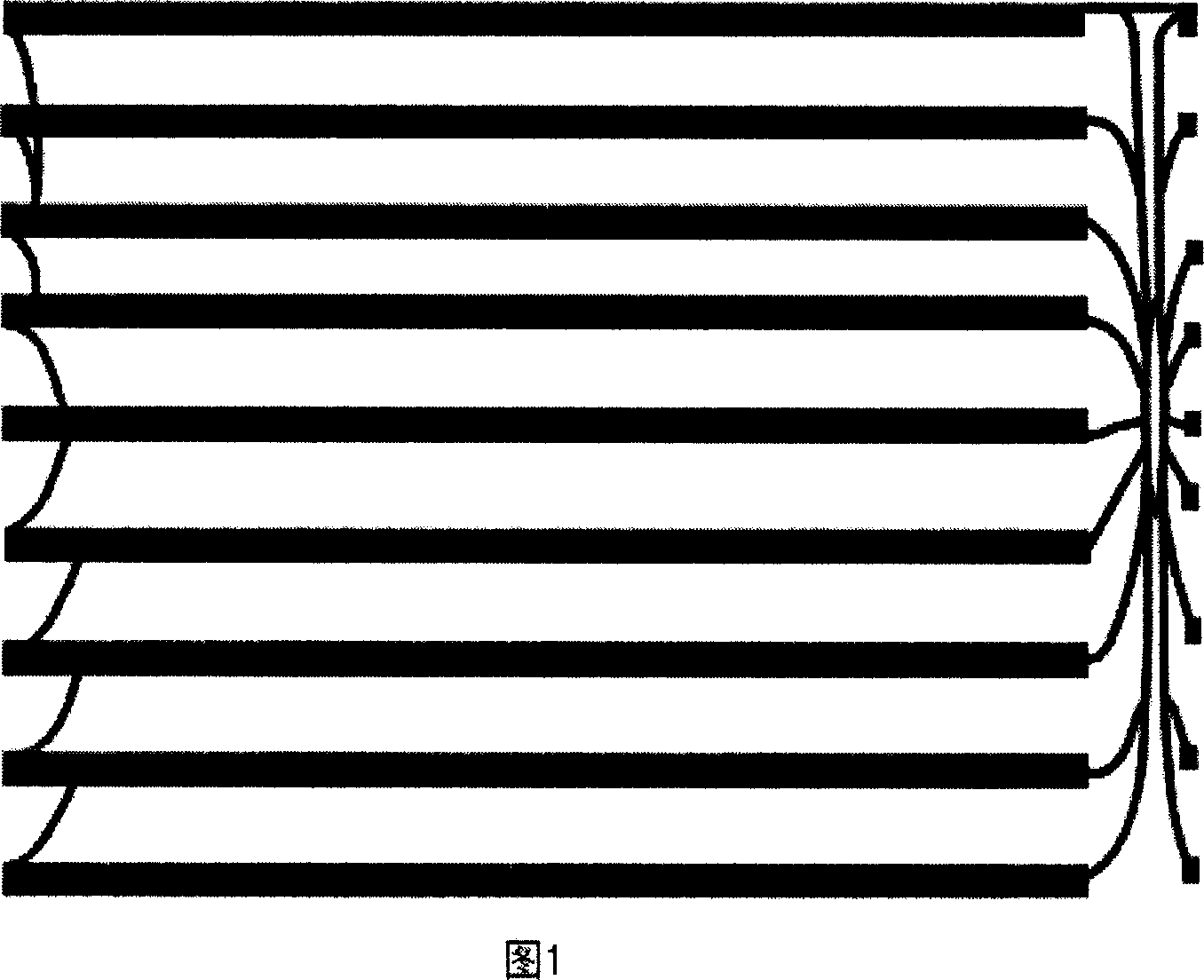

Exhausting silencing apparatus for air-tight rotary compressor

InactiveCN1112518CPhase changeChange noiseRotary/oscillating piston combinations for elastic fluidsSilencing apparatusEngineeringNoise reduction

A discharge muffler of a hermetic rotary compressor has a simple structure, and reduces the noises which occur due to pulsation of refrigerant and impact to a valve when the refrigerant, which is compressed in an inner space of a cylinder of the compressor, is discharged. The discharge muffler includes a muffler body which is disposed above an upper flange to define a noise reducing space with the upper flange, and has a pair of discharge openings through which the refrigerant, which is discharged to the noise reducing space, is discharged, and a phase varying means for preventing the noises which occur due to the pulsation of the refrigerant and the impact to the valve which is disposed at the discharge port, from being discharged together with the refrigerant. The phase varying means also functions to vary the phases of the noises and to counterbalance the noises. The phase varying means comprises a pair of covers which extend from the muffler body toward centers of the discharge openings to cover approximately half portions of the discharge openings from above and from below, respectively, in an alternating pattern. Accordingly, the noise, which is produced when the refrigerant is discharged, is blocked by a pair of covers which are disposed at the discharge openings, and the phases of the noises are varied, so that the noises are counterbalanced. As a result, the great noise reduction effect is guaranteed with a simple structure.

Owner:SAMSUNG ELECTRONICS CO LTD

A multi-degree-of-freedom manipulator joint based on linear drive of smart materials

The invention provides a linear-driven multi-freedom-degree mechanical arm joint based on a smart material. Under the excitation of signals, a moving sliding block is pulled by an SMA driving wire to drive a split fork to move so as to pull a joint connecting frame to rotate, and the joint connecting frame is made to swing around the perpendicular plane with a shoulder end brace as a center. At a fore joint driving position, a moving sliding block is pulled by an SMA driving wire to pull a split fork to rotate, and a joint connecting frame is driven to swing around the horizontal plane with a shaft hole of the perpendicular plate side of the joint connecting frame as a center. At two fore joint driving positions, an SAM driving wire on a joint connecting frame drives a moving sliding block to drive the split fork to rotate around an outer side shaft hole of the joint connecting frame so as to drive an axial joint connecting frame to rotate in the axis direction, and the multi-freedom-degree movement of the mechanical arm joint is achieved finally. According to the linear-driven multi-freedom-degree mechanical arm joint based on the smart material, due to the fact that the SMA wires are adopted, the linear output of power driving can be achieved directly, and the defects of energy consumption and noise caused by using a middle mechanism in the axial driving of a traditional motor are overcome.

Owner:HARBIN ENG UNIV

Energy-saving and environment-friendly fruit juicer

InactiveCN108937516AJuicing hygiene and environmental protectionChange the problem that is not easy to cleanStrainersEngineering

The invention relates to the technical field of environment-friendly machines, and discloses an energy-saving and environment-friendly fruit juicer. The juicer comprises a fruit placement box, threaded holes are formed in the two sides of the top of the fruit placement box, third fixing blocks are connected to the tops of the threaded holes, and spiral hand wheels are connected to the tops of thethird fixing blocks; a connecting box is connected to the ends, away from the fruit placement box, of the third fixing blocks, sliding grooves are connected to the inner side of the connecting box, sliding blocks are connected to the inner sides of the sliding grooves, supporting blocks are connected to the ends, away from the sliding grooves, of the sliding blocks, first springs are connected tothe surfaces, back to each other, of the two supporting blocks, the ends, away from the supporting blocks, of the first springs are fixed to the inner wall of the connecting box, and first fixing blocks and third fixing blocks are connected to the surfaces, opposite to each other, of the two supporting blocks. By means of the energy-saving and environment-friendly fruit juicer, the problems are solved that a fruit juicer body causes noise and the inner wall of the fruit juicer body is inconvenient to clean.

Owner:WUHU LE CHUANG ELECTRONICS TECH CO LTD

A Method for Recognition and Compensation of Spatio-temporal 3D Noise in Area Array Staring Infrared Remote Sensing Images

ActiveCN108470325BReduce typing errorsRapid positioningImage enhancementImage analysisCurrent noiseInfrared remote sensing

The invention provides a space-time three-dimensional noise recognition and compensation method for an area array staring infrared remote sensing image. This method aims at the unsteady three-dimensional noise generated by the row axis, column axis and time axis in the area array staring infrared image, and realizes accurate noise location and compensation processing. The method is realized through five processes of sample selection, spatial filtering, noise primary selection, noise location file making, and noise compensation. The present invention overcomes the disadvantages of large amount of calculation and easy loss of image information when the current noise filtering method is applied to an area array infrared remote sensing image sequence with spatiotemporal three-dimensional unsteady noise, and can be applied to fields such as on-orbit processing and quality improvement of infrared images. It is also helpful to improve the geometric matching accuracy of area array infrared images.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

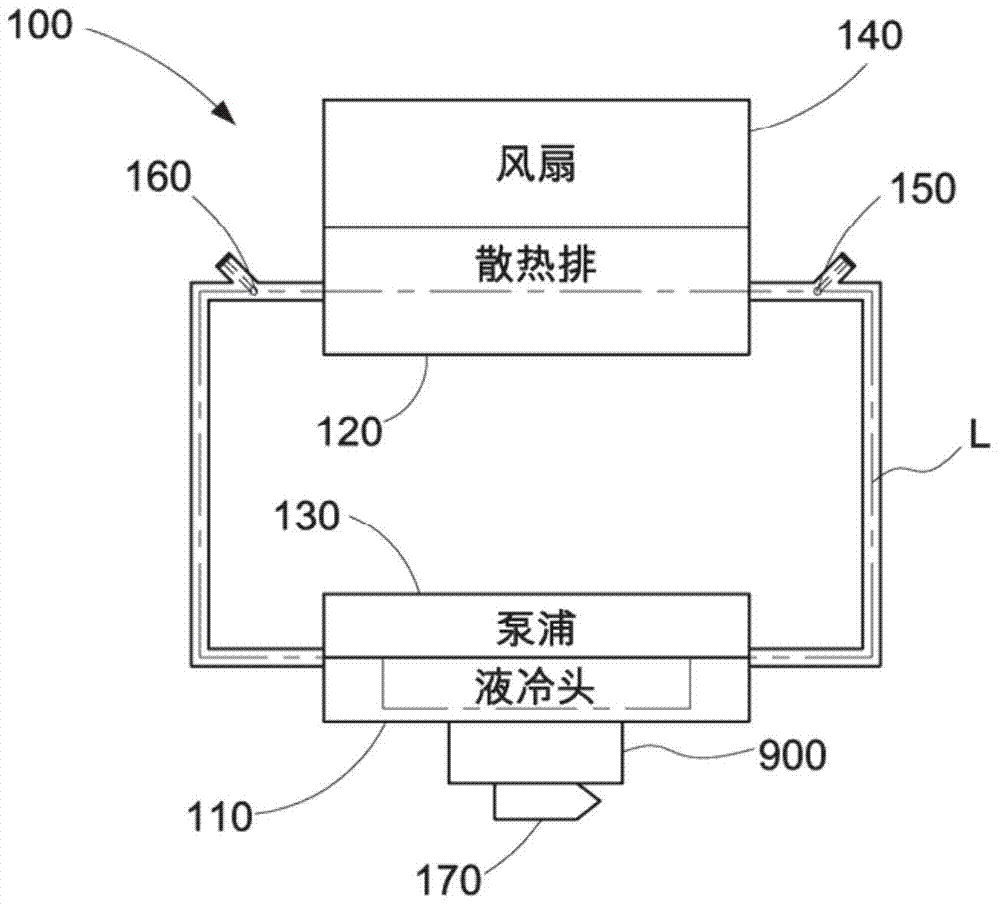

Liquid cooling heat dissipation device and liquid cooling heat dissipation temperature control method

ActiveCN104679191BChange noiseChange frequencyDigital data processing detailsTemperature control using electric meansEngineeringCooling temperature

A liquid-cooling heat dissipation device is used for implementing a liquid-cooling heat dissipation temperature control method to pump a cooling liquid to cool a heat source. The liquid-cooled heat dissipation temperature control method includes contacting a heat source with a liquid cooling head to absorb the heat generated by the heat source, and allowing the cooling liquid to pass through for heat exchange; connecting a heat sink to the liquid cooling head to form a cooling liquid circulation Flowing circulation pipeline; detect the temperature of the heat source, the inlet liquid temperature of the heat sink, and the liquid outlet temperature of the heat sink; judge whether the temperature of the heat source is greater than a high temperature warning value, and calculate the temperature between the liquid outlet temperature and the liquid inlet temperature Difference. When the temperature of the heat source is not greater than the high temperature warning value, the method adjusts the forced cooling efficiency of the radiator or the flow rate of the pumped cooling liquid according to the temperature difference, so as to meet the temperature control requirements and noise control.

Owner:GIGA BYTE TECH CO LTD

Transmission mechanism of sewing machine

InactiveCN105177880AReduce designSimple structureSewing-machine control devicesGear wheelAgricultural engineering

The invention belongs to the technical field of sewing machines and particularly relates to a transmission mechanism of a sewing machine. The transmission mechanism comprises a turnover shaft, a lower shaft and a tensioning wheel adjusting shaft. A large synchronous pulley is arranged on the turnover shaft. A lower shaft synchronous pulley is arranged on the lower shaft. A tensioning wheel is arranged on the tensioning wheel adjusting shaft. A double cogged synchronous belt is arranged outside the tensioning wheel and the large synchronous pulley. The tensioning wheel and a large gear are in connection and transmission with inner side teeth of the double cogged synchronous belt. The lower shaft synchronous pulley is in connection and transmission with outer side teeth of the double cogged synchronous belt. The turnover shaft is connected with an upper shaft through a transmission device and drives the upper shaft to act. According to the transmission mechanism, the double cogged synchronous belt does not need to be soaked into lubricating oil in the operation process, the design of a gearbox body on a base plate can be omitted, the structure is simplified, and the cost is saved; the tension of the double cogged synchronous belt can be adjusted through the tensioning wheel, and matching can be achieved without replacing synchronous belts of different length tolerances, so that difficulty of the assembling process is simplified, and use is more convenient.

Owner:JACK SEWING MASCH CO LTD

A refrigerator refrigeration system

ActiveCN111829259BReduce in quantitySimple refrigeration structureLighting and heating apparatusDomestic refrigeratorsCold airIcebox

Owner:GUANGDONG GALANZ GRP CO LTD +1

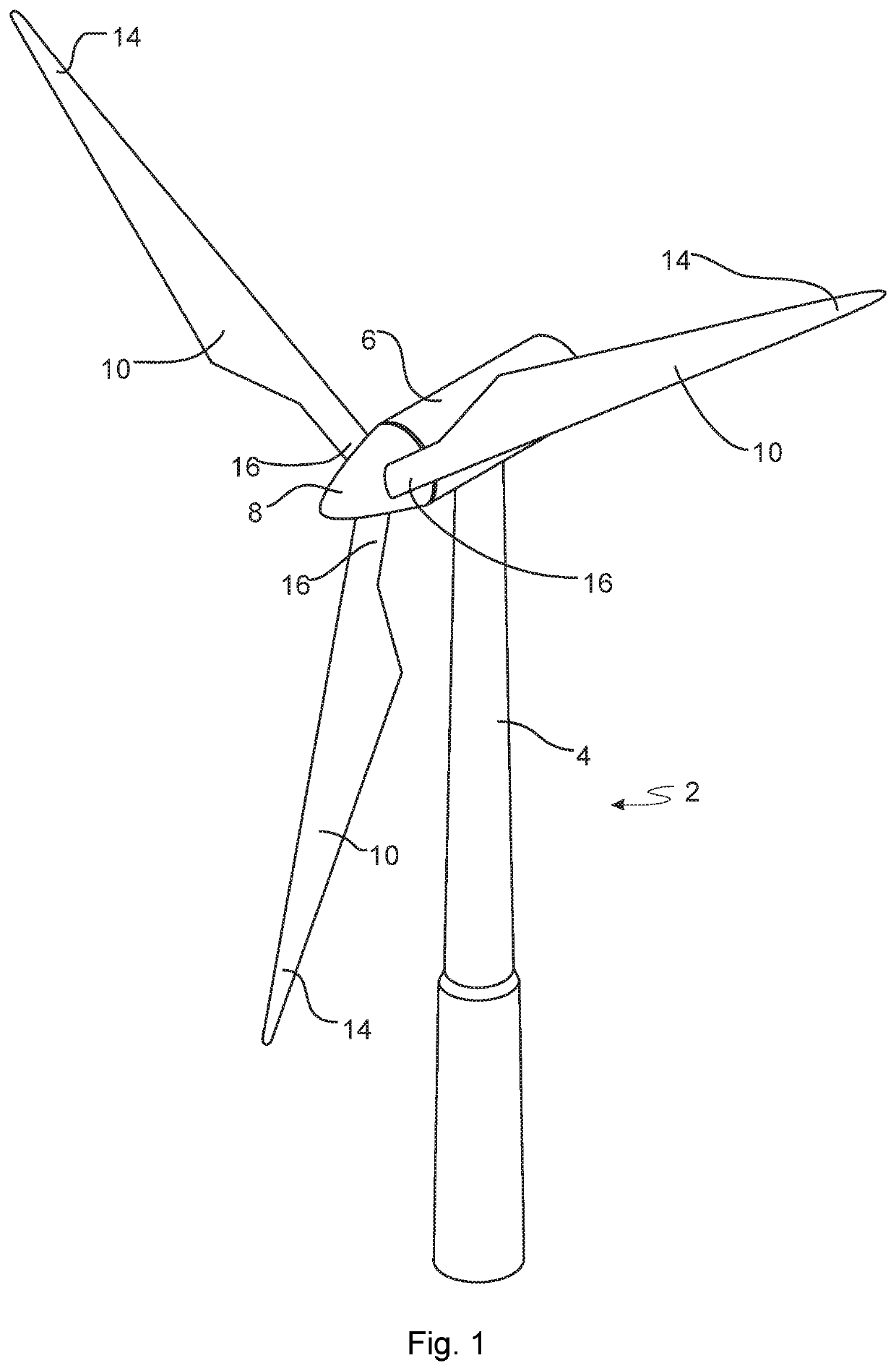

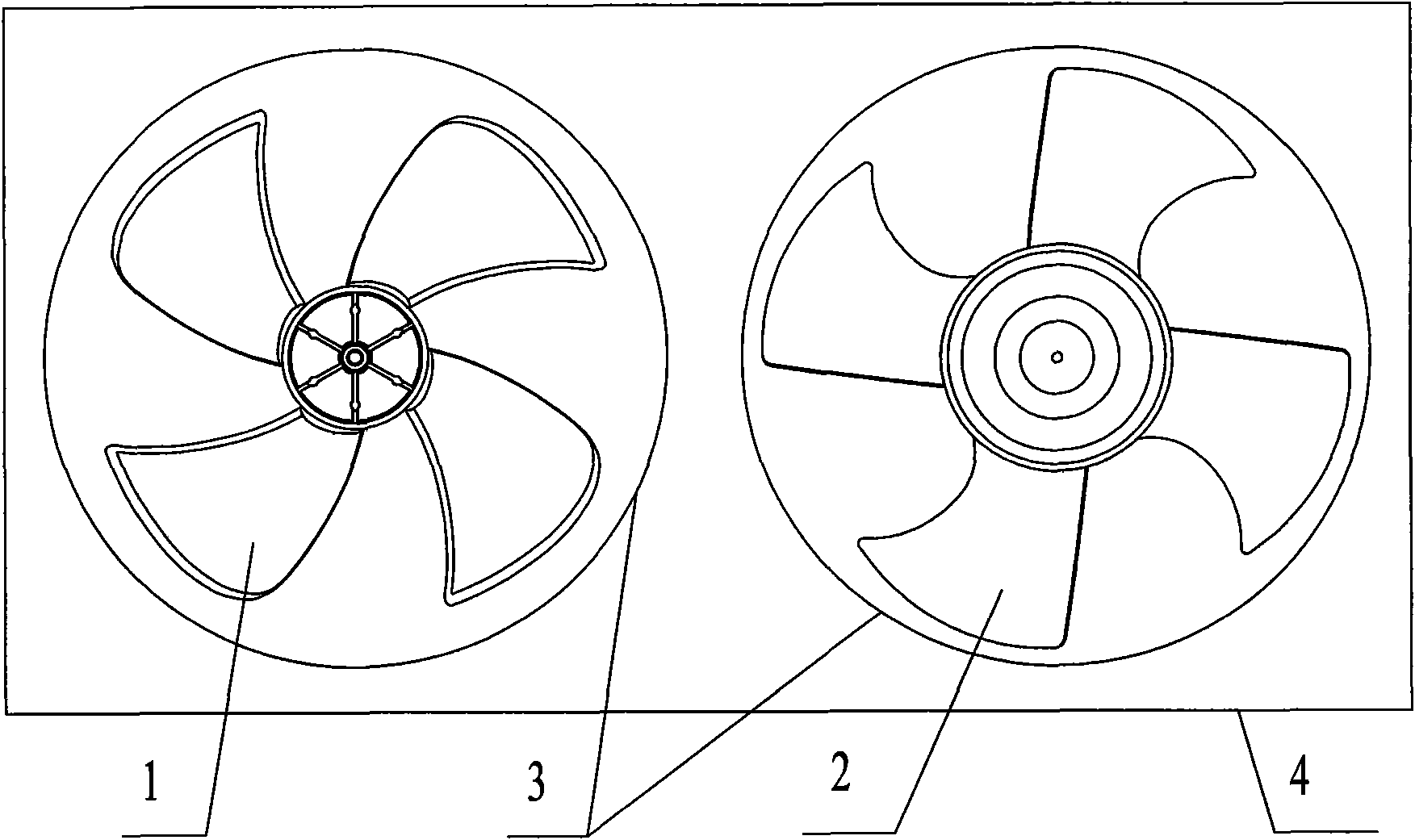

Wind turbine blade lightning protection system

ActiveUS20220003214A1Change noiseLess stressEngine manufactureFinal product manufactureTurbine bladeElectrical connection

Disclosed is a wind turbine blade comprising a shell body, a down conductor arranged in the shell body for conducting lightning current to ground, an electrical connector arranged in electrical connection with the down conductor, a lightning receptor element arranged at a surface of the shell body or outside the shell body, the lightning receptor element being in electrical connection with the electrical connector. A method for manufacturing a wind turbine blade with a lightning protection system is also provided.

Owner:LM WIND POWER AS

Double axial-flow wind wheel system

ActiveCN101644274BIngenious designImprove performancePump componentsPump installationsEngineeringAir conditioning

The invention provides a double axial-flow wind wheel system, comprising a first axial-flow wind wheel (1) and a second axial-flow wind wheel (2); wherein the rotate speed of the first axial-flow wind wheel (1) is N1 circle / minute, the number of blade is Z1, and rotating basic frequency F1=Z1XN1 / 60 Hz; and the rotate speed of the second axial-flow wind wheel (w) is N2 circle / minute, the number ofblade is Z2, and rotating basic frequency F2=Z2XN2 / 60 Hz. The system is characterized in that the rotating basic frequency between the first axial-flow wind wheel (1) and the second axial-flow wind wheel (2) is in the range of 4-20 Hz. When being used in an outer machine of an air conditioning room with top wind out structure, side wind out structure or oblique upper wind out structure, because the rotating basic frequency between the first axial-flow wind wheel (1) and the second axial-flow wind wheel (2) is from 4 to 20 Hz, the system can change the rotating noise voice pressure and the voice powder of the double axial-flow wind wheel, thereby greatly weakening or completely removing the beat vibration formed by overlapping the rotating noise of the two wind wheels, obviously improving the tone quality of the outer machine system of the double axial-flow wind wheel, effectively preventing the metal plate structure from resonating, and reaching the aim of reducing the vibration and improving the reliability of the whole machine.

Owner:MIDEA GRP CO LTD

Large power pipe superconductive radiator

InactiveCN1921744ASpeed up distributionChange noiseDigital data processing detailsSemiconductor/solid-state device detailsEngineeringLife time

Owner:高云书

Elevator Brake Freewheeling Control Method, Device, Equipment and Medium

ActiveCN111204631BChange noiseDelayed release timeBrake actuating mechanismsElevatorsLoop controlBrake

Owner:HITACHI BUILDING TECH GUANGZHOU CO LTD

Universal fuel engine

ActiveCN102168613BNo noiseChange noiseInternal combustion piston enginesExhaust apparatusCombustion chamberCooling chamber

The invention relates to an engine, particularly to a universal fuel engine. The universal fuel engine comprises cylinders connected by exhaust channels. The universal fuel engine is characterized in that the cylinders comprise an air feeding cylinder, a working cylinder and an air exhaust cylinder which are connected in sequence; the exhaust channels which connect the cylinders are sequentially provided with an air valve 1, an air valve 2, an air valve 3 and an air valve 4; the exhaust channel between the air feeding cylinder and the working cylinder is provided with a burning chamber; and the exhaust channel between the working cylinder and the air exhaust cylinder is provided with a cooling chamber. According to the invention, the engine is convenient to use, has simple structure, highmechanical efficiency and no noise. The engine can use any fuel and can save energy, thus being suitable for wide popularization and application.

Owner:NANTONG CITY TONGZHOU DISTRICT PINZHANG TEXTILE PROD

Actuator driving device for executing positive and negative energization method under pulse width modulation control

An actuator driving device drives an actuator connected to an output terminal. The control unit of the actuator driving device includes a PWM delay time setting unit, a first duty ratio setting unit, and a second duty ratio setting unit. The PWM delay time setting unit sets a delay time of pulse width modulation control for a driving voltage to be applied to the output terminal and outputs setting information to the first and second duty ratio setting units. The first duty ratio setting unit sets the first duty ratio for a first PWM output unit, and the second duty ratio setting unit sets the second duty ratio for a second PWM output unit. When positive and negative energization is performed, the control unit controls to reduce the amount of change in current in the current peak of a PWM waveform by providing a short-circuit period in response to the energization amount.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com