A multi-degree-of-freedom manipulator joint based on linear drive of smart materials

A technology of linear drive and intelligent materials, applied in the field of manipulators, can solve the problems of increasing the weight of manipulators, not involving multiple degrees of freedom of manipulators, increasing energy consumption, etc., to achieve increased use value, convenient installation and maintenance, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in more detail below in conjunction with accompanying drawing example:

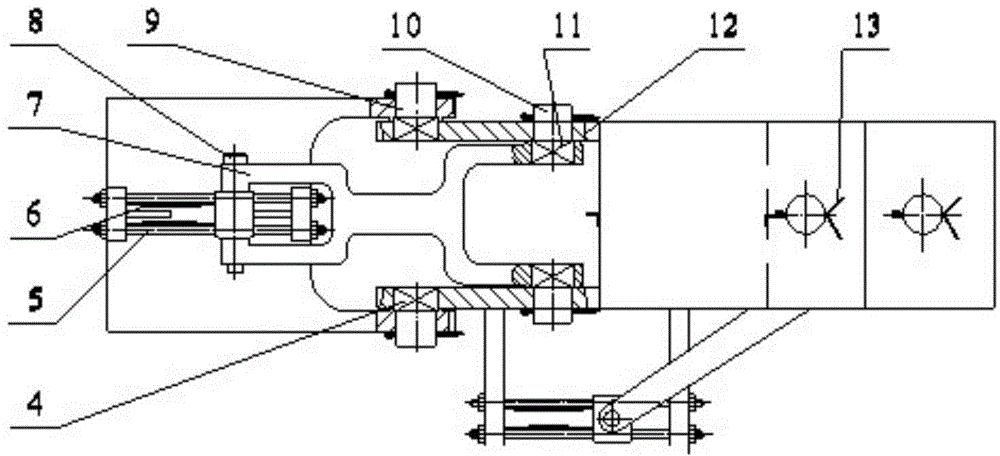

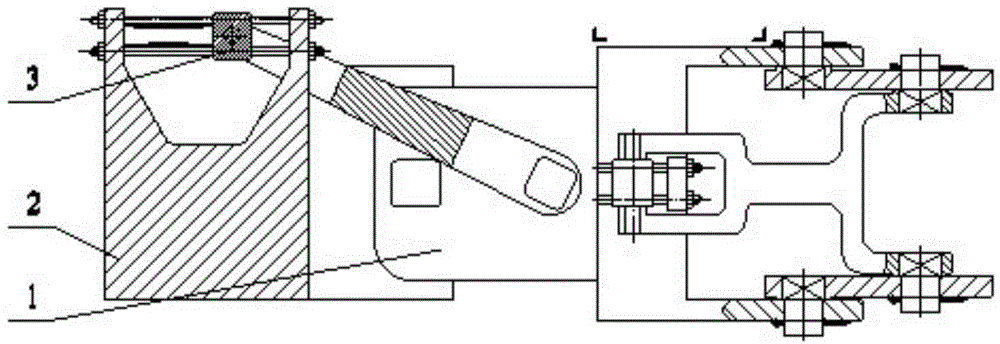

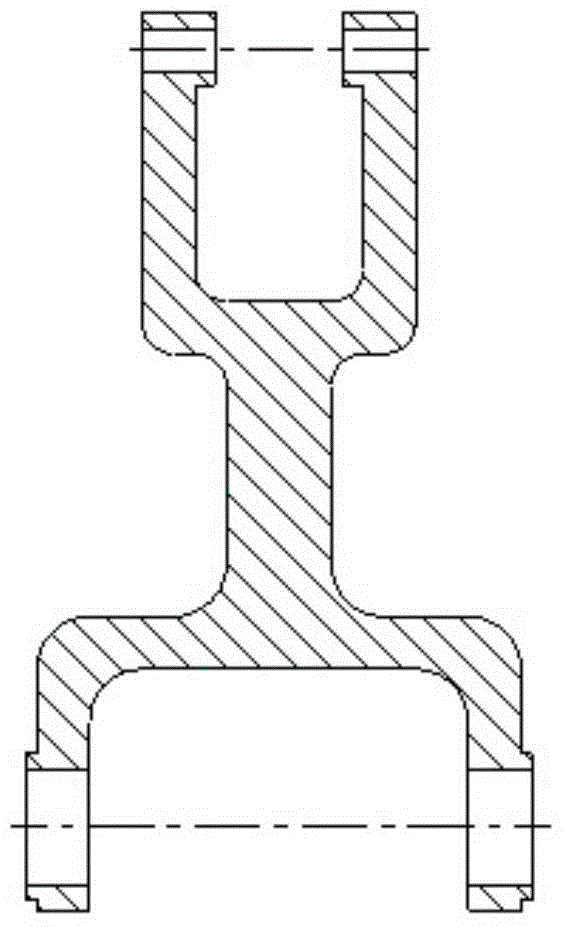

[0020] 1-9, the structure of the present invention mainly includes three parts: plane vertical drive joint I, plane horizontal drive joint II, and plane circumferential drive joint III. A multi-degree-of-freedom manipulator joint structure is obtained by combining and assembling the three parts. It is mainly realized through the combination of plane vertical drive joint I and plane horizontal drive joint II, plane horizontal drive joint II and plane circular drive joint III, that is, I+I+II combination structure, plane vertical drive joint I and plane horizontal drive joint II is assembled and connected through the joint connecting frame 12 and 20, and the plane horizontal driving joint II and the plane circumferential driving joint III are assembled and connected through the joint connecting frame 31 and 37; Four sliding shafts 5 are connected by 4 bolts, one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com