Large power pipe superconductive radiator

A high-power, heat sink technology, used in semiconductor devices, semiconductor/solid-state device components, instruments, etc., can solve the problems of high noise, poor reliability, power consumption, etc., to eliminate noise, prolong service life, and change the noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

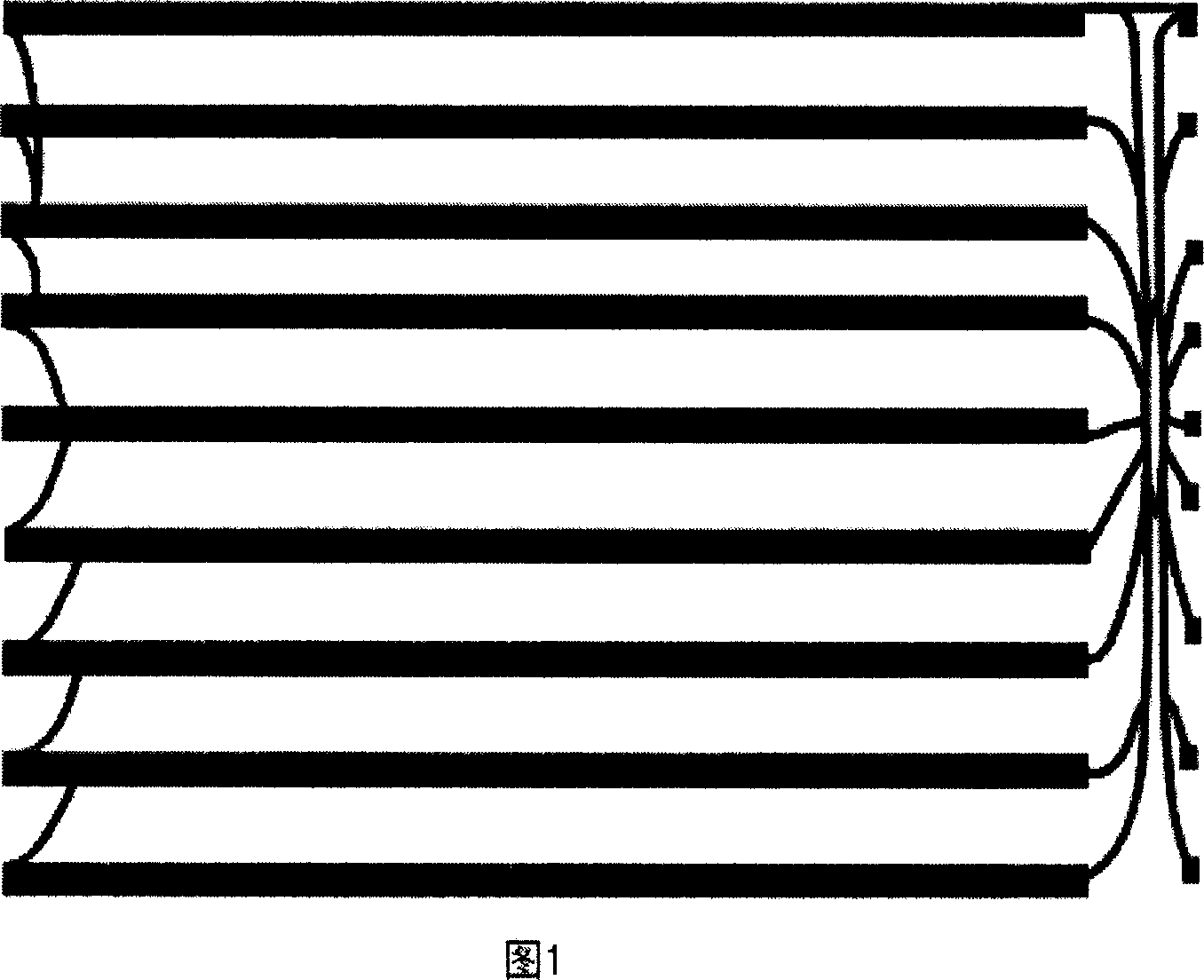

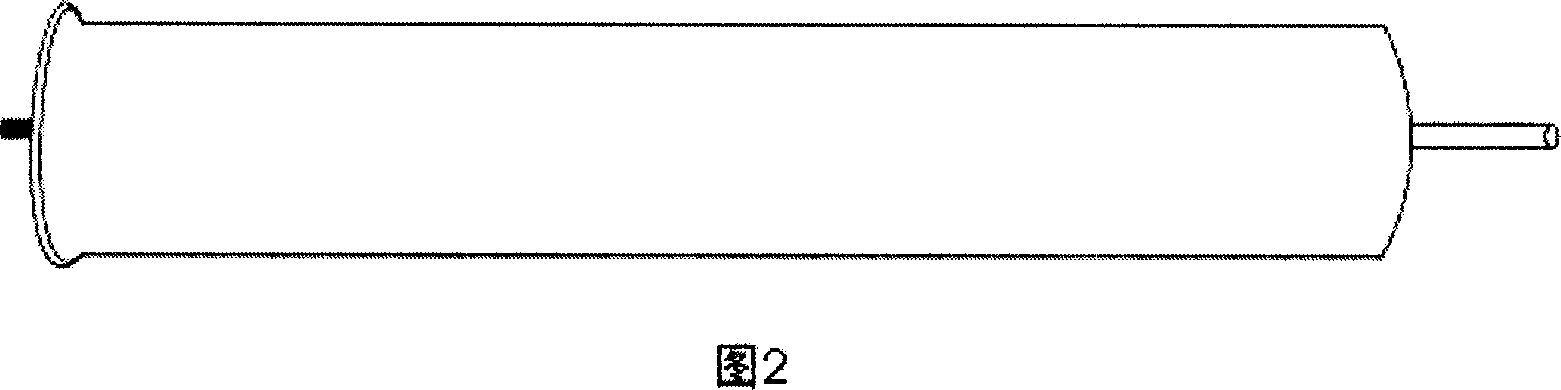

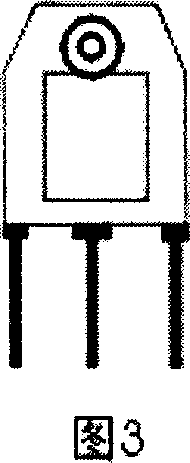

[0016] Put the superconducting heat pipe (copper tube) in Figure 2 into the aluminum alloy radiator in Figure 1, and after expanding the tube, it will be closely combined with the aluminum alloy radiator. In Figure 4 above, a screw is welded to fix the high-power tube. On the cross-section of the other end, Figure 5 welds a copper tube for vacuuming, and superconducting medium is added. The two ends of the copper tube are fully sealed to form a fully sealed Vacuum cooling system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com