Universal fuel engine

An engine and fuel technology, which is applied to combustion engines, internal combustion piston engines, engine components, etc., can solve the problems of inability to use solid fuels, high engine noise, and low efficiency, and achieve the effects of simple structure, improved mechanical efficiency, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

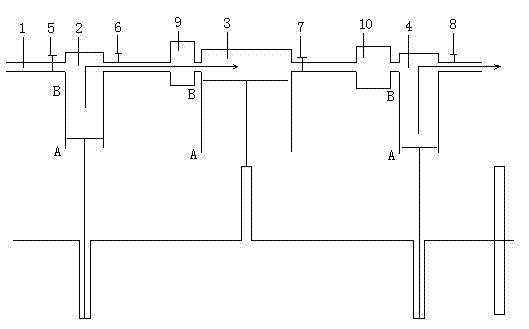

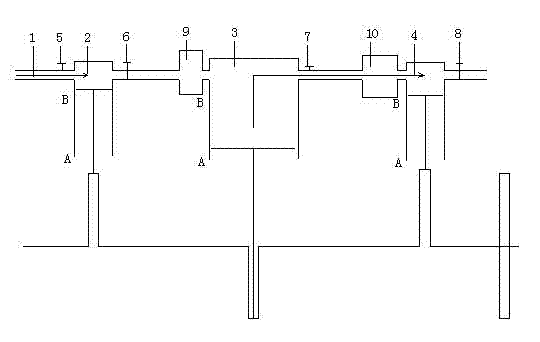

[0015] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a cylinder connected by an exhaust channel 1, the cylinder is an air delivery cylinder 2, a working cylinder 3, and an exhaust cylinder 4 connected in sequence, and the exhaust channel 1 connected to the cylinder is sequentially provided with an air valve 15, an air valve 2 6, air valve 3 7, air valve 4 8, a combustion chamber 9 is set on the exhaust passage 1 between the air delivery cylinder 2 and the working cylinder 3, and a combustion chamber 9 is arranged on the exhaust passage 1 between the working cylinder 3 and the exhaust cylinder 4 There is a cooling chamber 10; the piston in the cylinder is connected with the power unit; the working cylinder 3 is provided with an insulating layer.

[0016] The piston of air delivery cylinder 2 moves from end A to end B, air valve 1 is closed, air valve 2 is opened, the air in air delivery cylinder 2 enters working cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com