Prefabricated lifting fish-belly corrugated steel web internal-prestress combined box beam and construction method thereof

A technology of corrugated steel webs and hoisting fish belly, which is applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., and can solve problems such as corrosion, potential safety hazards, and low durability of external prestressed beams

Inactive Publication Date: 2015-12-23

SOUTHEAST UNIV +1

View PDF10 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, corrugated steel web composite beams need to be prestressed to ensure the stiffness of the mid-span and prevent the concrete slab of the mid-span lower flange from cracking. At present, external prestressed beams are mainly used in engineering, but the durabil

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

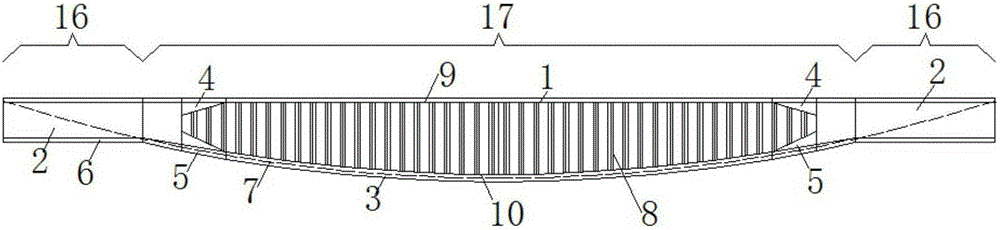

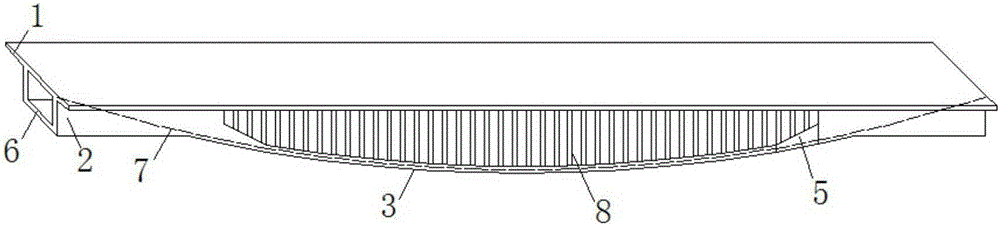

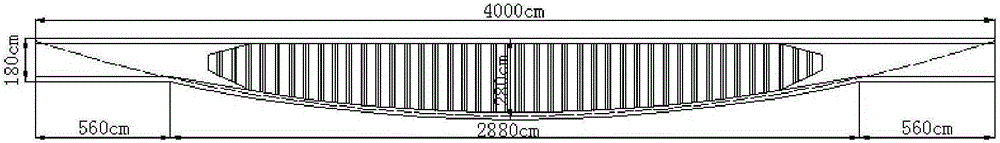

The invention discloses a prefabricated lifting fish-belly corrugated steel web internal-prestress combined box beam. A fish-belly-shaped beam section is adopted in the midspan position of the box beam. The bottom flange of the fish-belly-shaped beam section is a concrete flange. A corrugated steel web is used as the web of the fish-belly-shaped beam section in the midspan position. Concrete box beams which are equally high are used as support beam sections. Internal-prestress tendons which are equally long are tensioned in a concrete box beam web of a support beam section of the lower flange of the midspan fish-belly-shaped beam section. Based on the prefabricated lifting fish-belly corrugated steel web internal-prestress combined box beam, a corresponding construction method is established, and the construction is safe, convenient and fast through the construction method. By means of the prefabricated lifting fish-belly corrugated steel web internal-prestress combined box beam and the construction method thereof, the rigidity of a beam body is improved substantially, the air exposure of prestressed cables of the corrugated steel web combined beam is avoided, the durability and reliability of a combined beam structure are improved substantially, and an obstacle for widely popularizing the corrugated steel web combined beam is eliminated.

Description

technical field [0001] The invention belongs to the field of transportation bridge and culvert engineering, and in particular relates to a prefabricated hoisting fish-belly corrugated steel web body prestressed composite box girder and a construction method thereof. Background technique [0002] Compared with ordinary concrete box girders, corrugated steel web composite girders use corrugated steel webs instead of concrete webs, which can greatly reduce their own weight. However, corrugated steel web composite beams need to be prestressed to ensure the stiffness of the mid-span and prevent the concrete slab of the mid-span lower flange from cracking. At present, external prestressed beams are mainly used in engineering, but the durability of external prestressed beams is low, and Fatigue is prone to occur, and after a certain number of years (20-30 years) of use, corrosion and fracture may occur, burying hidden safety hazards of this structure, thus restricting the wide appl...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E01D2/04E01D21/00E01D101/28

Inventor 陈齐风郝天之高建明邱波徐赵东王龙林罗月静黎力韬李淑芬彭蓉于孟生王莹

Owner SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com