Compact type redundant sealing structure

A sealing structure, compact technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems that the sealing redundant design method cannot be implemented, it is difficult to obtain a satisfactory sealing effect, and the sealing redundant design is difficult, so as to avoid Oil leakage phenomenon, compact structure, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

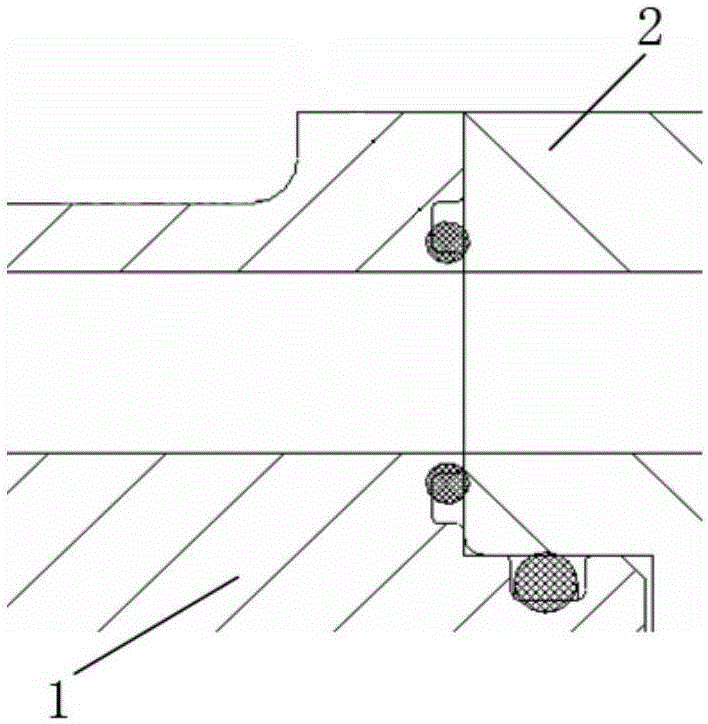

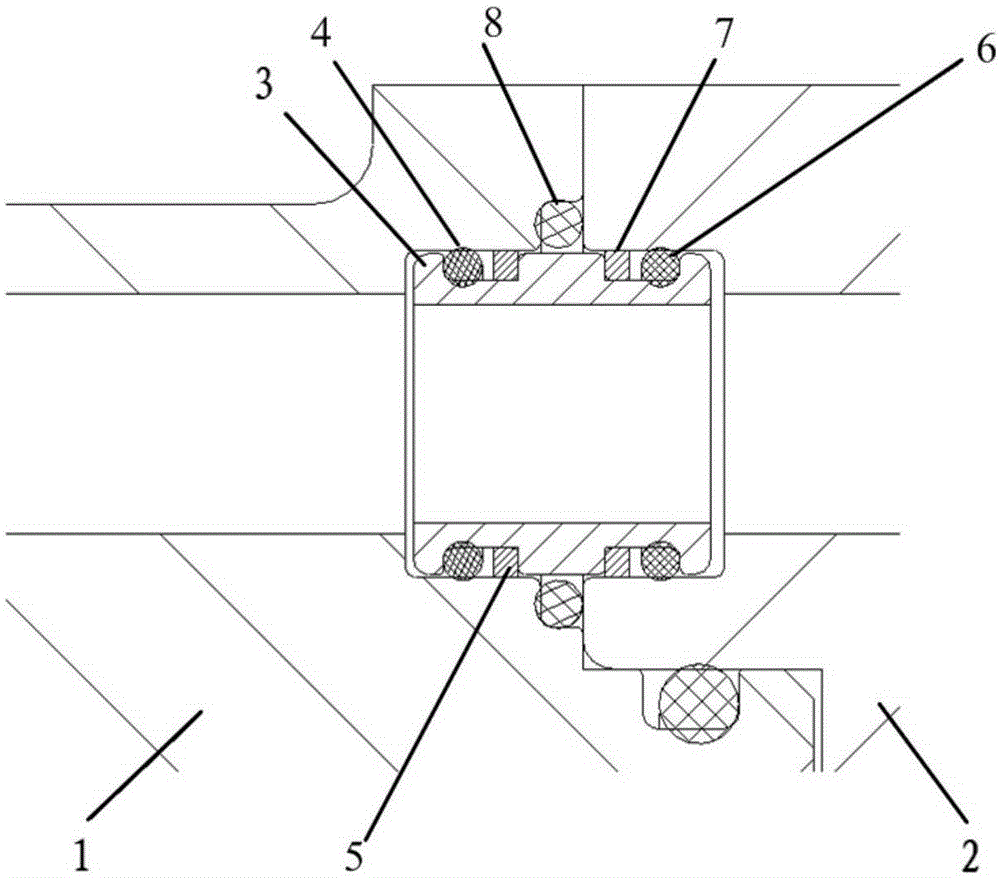

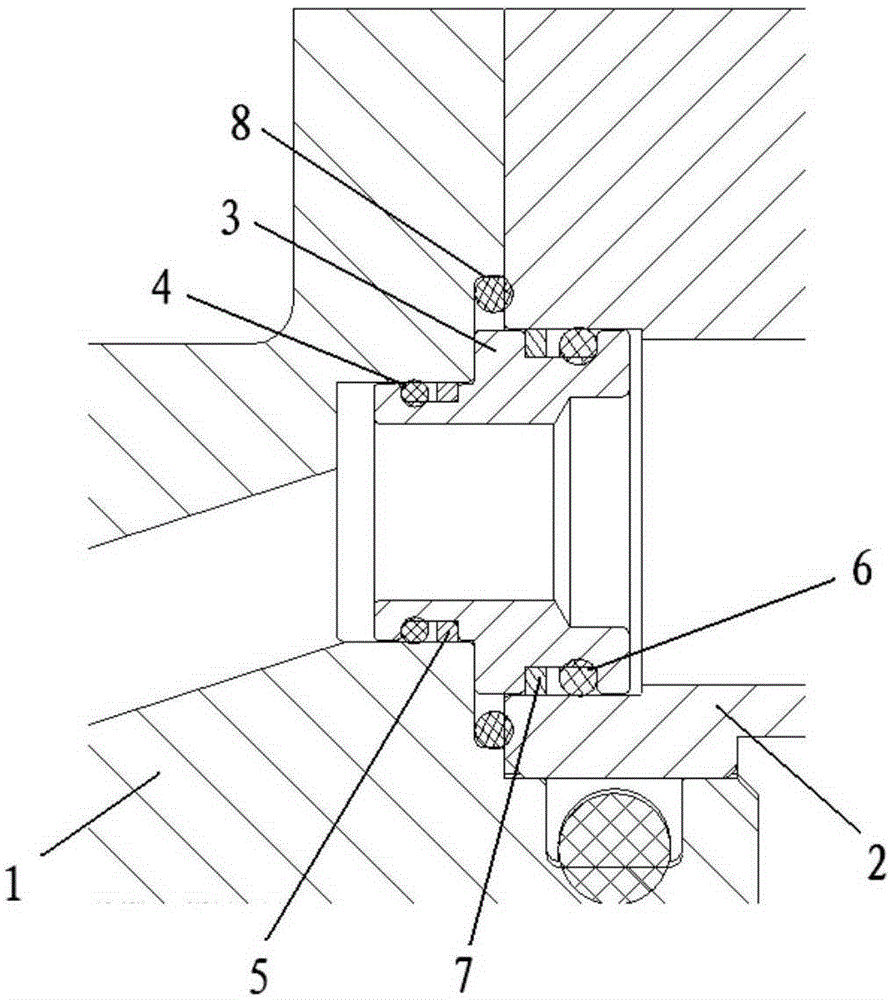

[0016] Such as figure 2 As shown, the first embodiment of the present invention includes a first housing 1, a second housing 2, an oil passing pin 3, a first sealing ring 4, a second sealing ring 6, a third sealing ring 8, a first Retaining ring 5 and second retaining ring 7.

[0017] The first housing 1 and the second housing 2 have oil through holes. In order to achieve redundant sealing, one end of the first housing 1 and the second housing 2 are respectively provided with an axial angle connected to the oil through holes. The first annular groove and the second annular groove, an oil-passing pin 3 is installed between the oil-passing holes of the first housing 1 and the second housing 2, and the two ends of the oil-passing pin 3 are connected to the first annular groove and the second annular groove respectively. The grooves are matched, there is a through hole in the oil through pin 3; the two ends of the through hole of the oil through pin 3 are as consistent as possible w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com