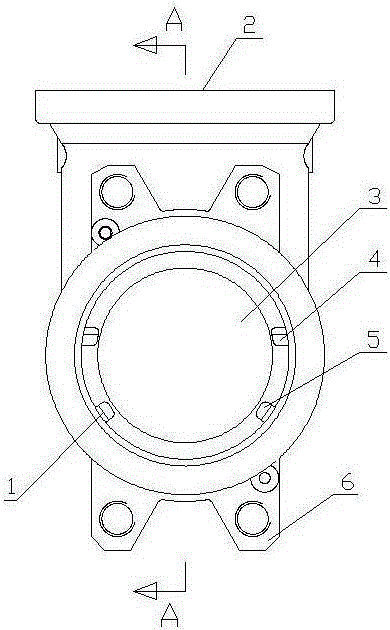

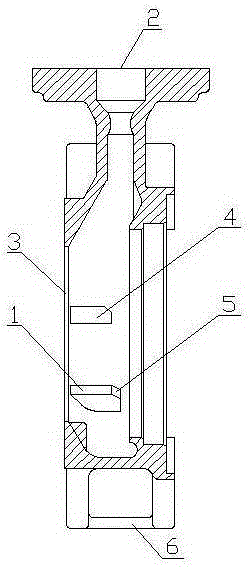

Valve body of knife type gate valve

A knife-type gate valve and valve body technology, which is applied to valve details, valve devices, valve housing structures, etc., can solve problems such as poor sealing performance, reduced sealing effect of closed valve, and reduced sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Such as figure 1 and figure 2 As shown, the knife-type gate valve body of the present invention includes a valve body, the valve body is a plate-shaped cavity structure, and its shape is approximately U-shaped, that is to say, its two valve walls are both U-shaped. The lower part of the valve body is arc-shaped, and two supporting feet 6 are cast on the arc-shaped lower part. There is an opening 2 on the upper end of the valve body for the gate to be inserted into the valve body. The two valve walls are processed with round holes 3 that are suitable for the diameter of the pipeline. The center of the circle coincides. Both sides of the inner surface of one of the two valve walls are cast with a first top block 4, and the end of the first top block 4 that is not connected to the valve wall is a plane, and the connecting line between the two first top blocks 4 It coincides with the transverse diameter line of the circular hole 3 . A second top block 1 is arranged und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com