Automatic constant-flow connector

An automatic, tapered head technology for pipes/couplings/fittings, connections with fluid shut-offs, engine components, etc., capable of solving problems such as water flow differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

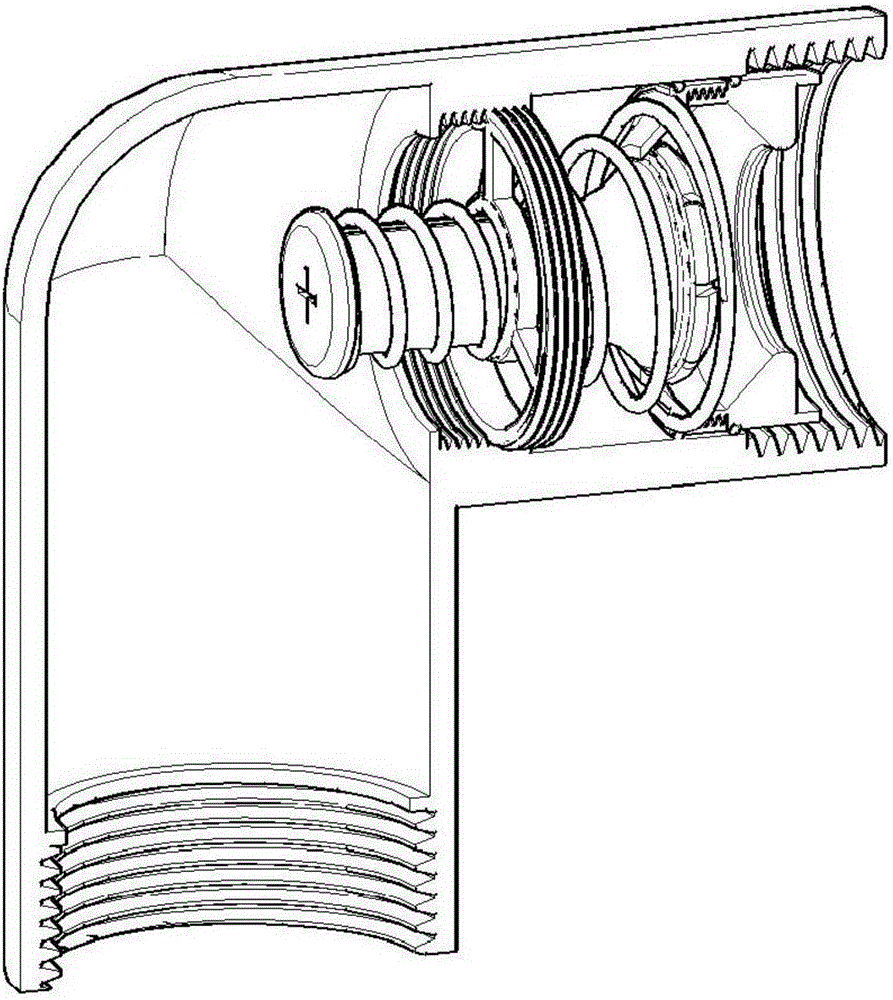

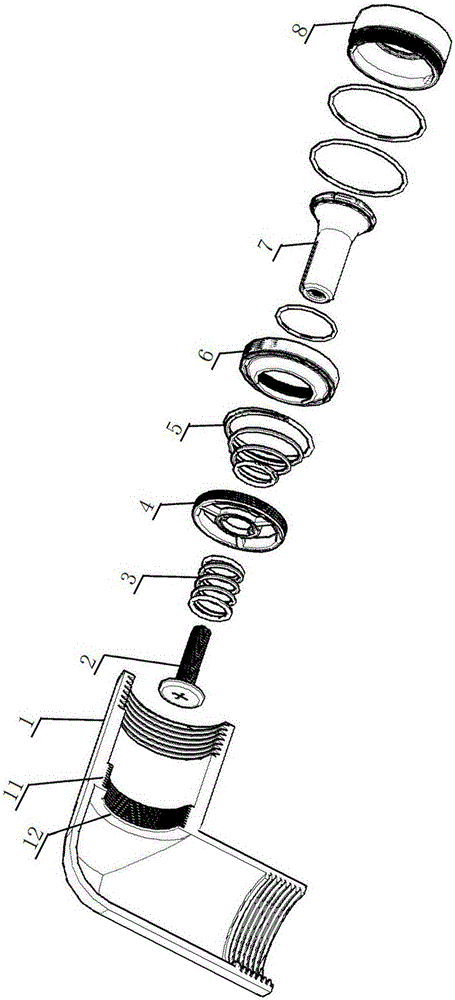

[0021] Such as Figure 1 to Figure 7 As shown, an automatic constant current joint is mainly composed of a joint 1, an adjustment screw 2, an adjustment spring 3, a bracket 4, a tower spring 5, a fixed cover 6, a valve core 7 and a fixed seat 8.

[0022] The inner wall of the joint 1 is provided with a ring of flanges 11 protruding inwards, and the flanges are provided with internal threads matching the external threads of the outer wall of the bracket. The lugs are used to mate with the brackets, which are threaded onto the lugs inside the joint.

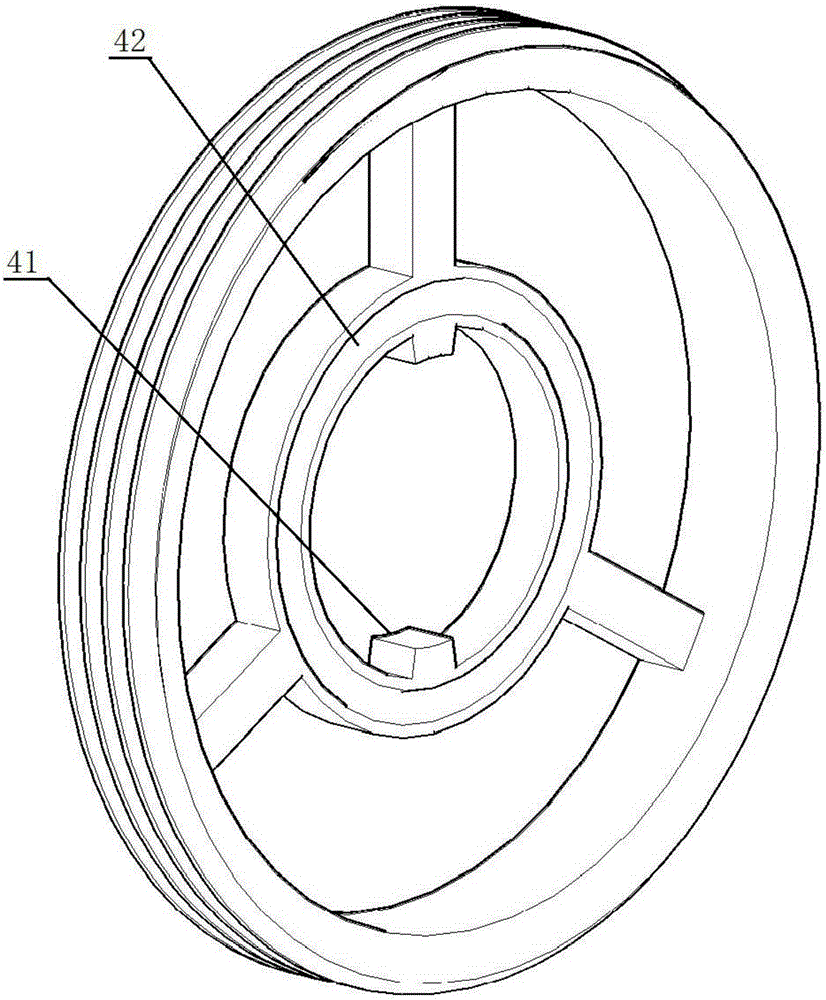

[0023] The bracket 4 is composed of a coaxial outer ring and an inner ring connected by a support arm, the inner wall of the inner ring is provided with a limit protrusion 41 protruding inward, and the valve stem of the valve core 7 is provided with a limit protrusion on the inner ring of the bracket. A corresponding limit groove 71 is formed, and a screw hole 72 coaxial with the valve stem is also provided on the valve stem. By ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com