Ultra-low frequency implementation method of magneto-electric intelligent digital vibration velocity sensor

A technology of speed sensor and vibration speed, which is applied in the direction of instruments, electric devices, electromagnetic means, etc., can solve the problems of difficult mass production and high production cost, and achieve the effect of mass production, production cost reduction and manufacturing cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

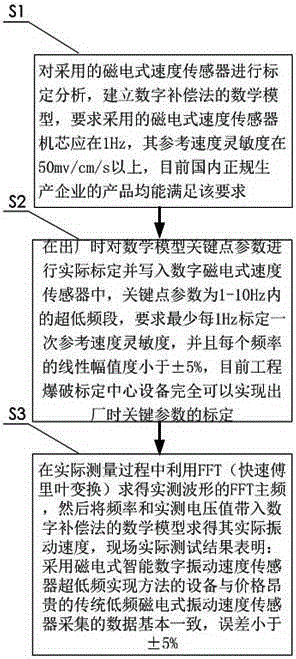

[0026] refer to figure 1 ,like figure 1 As shown, a method for realizing ultra-low frequency of a magnetoelectric intelligent digital vibration velocity sensor comprises the following steps:

[0027] S1. Carry out calibration analysis on the magnetoelectric speed sensor used, and establish a mathematical model of the digital compensation method. It is required that the core of the magnetoelectric speed sensor used should be at 1Hz, and its reference speed sensitivity should be above 50mv / cm / s. At present, domestic The products of regular manufacturers can meet this requirement;

[0028] S2. When...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap