Detection method and characterization method of microporous defects in cold-drawn seamless steel pipes

A technology of seamless steel pipe and detection method, which is applied in the directions of optical testing flaws/defects, preparation of samples for testing, etc., can solve the problems such as the lack of detection methods and evaluation standards for microporous defects in the core of cold-drawn seamless steel pipes. Achieving the effect of solving quality inspection problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] (3) The preparation of the sample, generally after grinding and polishing, a certain number of pits are inevitably distributed on the grinding surface of the sample, and foreign matter such as polishing agents, polishing fabrics, sand grains, etc. are often distributed in the pits, These foreign bodies have a strong binding force with the matrix, and it is not easy to clean them by conventional methods. In this way, when observing under a microscope, the above-mentioned pits are easily confused with microporous defects, thereby affecting the inspection efficiency and quality; in order to solve the above problems, the present invention The applicant chooses clean silk cloth as the polishing fabric, and clear water as the polishing agent. Firstly, the sample polished in the previous step is polished on a polishing machine to remove the polishing agent, polishing fabric, sand, etc. attached to the sample and inside the pit. Foreign matter, and then use alcohol and hot water...

Embodiment 1

[0051] The specification of embodiment 1 is Detection of Microporous Defects in Cold-drawn Seamless Steel Tubes for 25Mn Ordinary Structures and Their Grading

[0052] Specific steps are as follows:

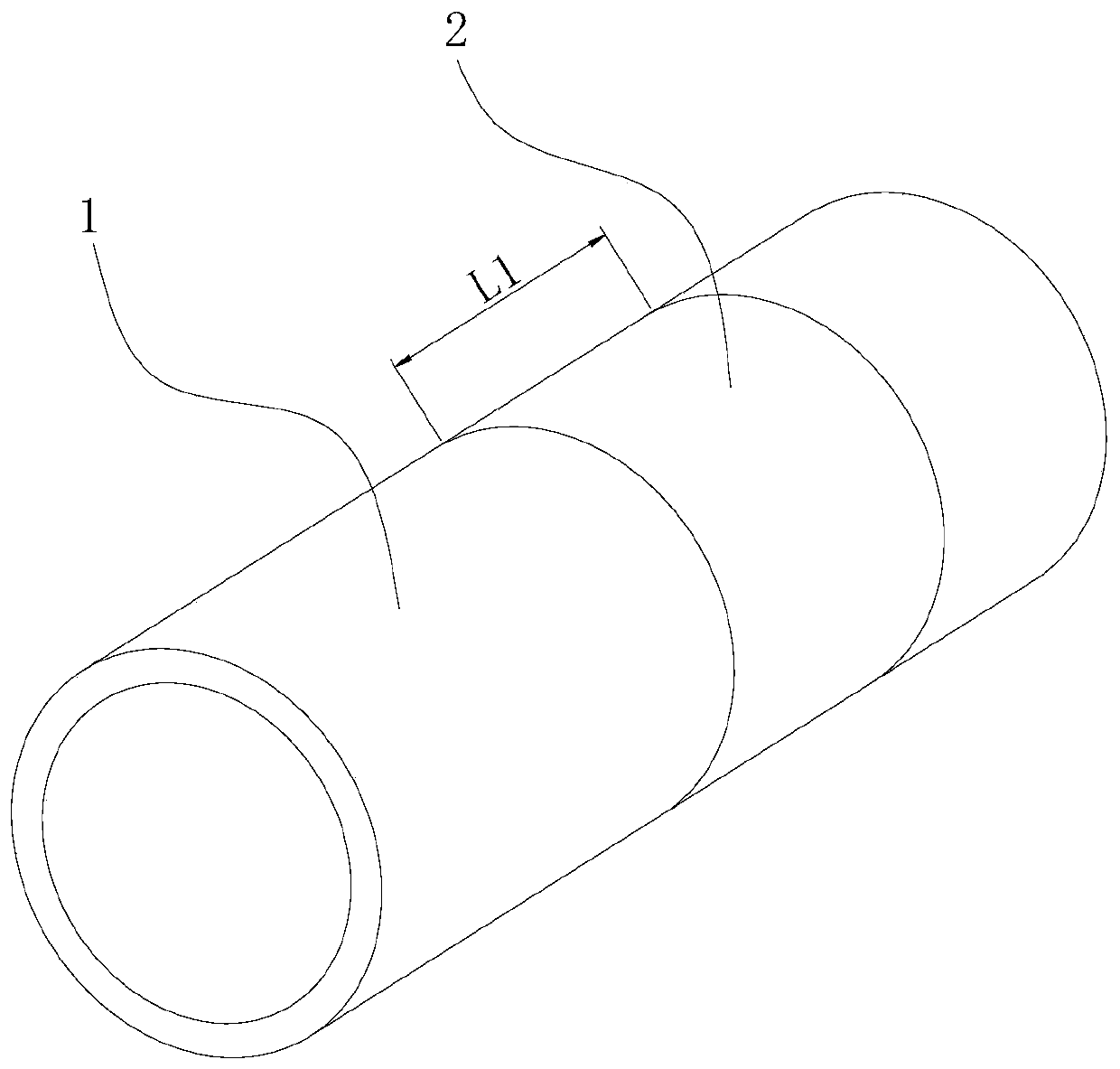

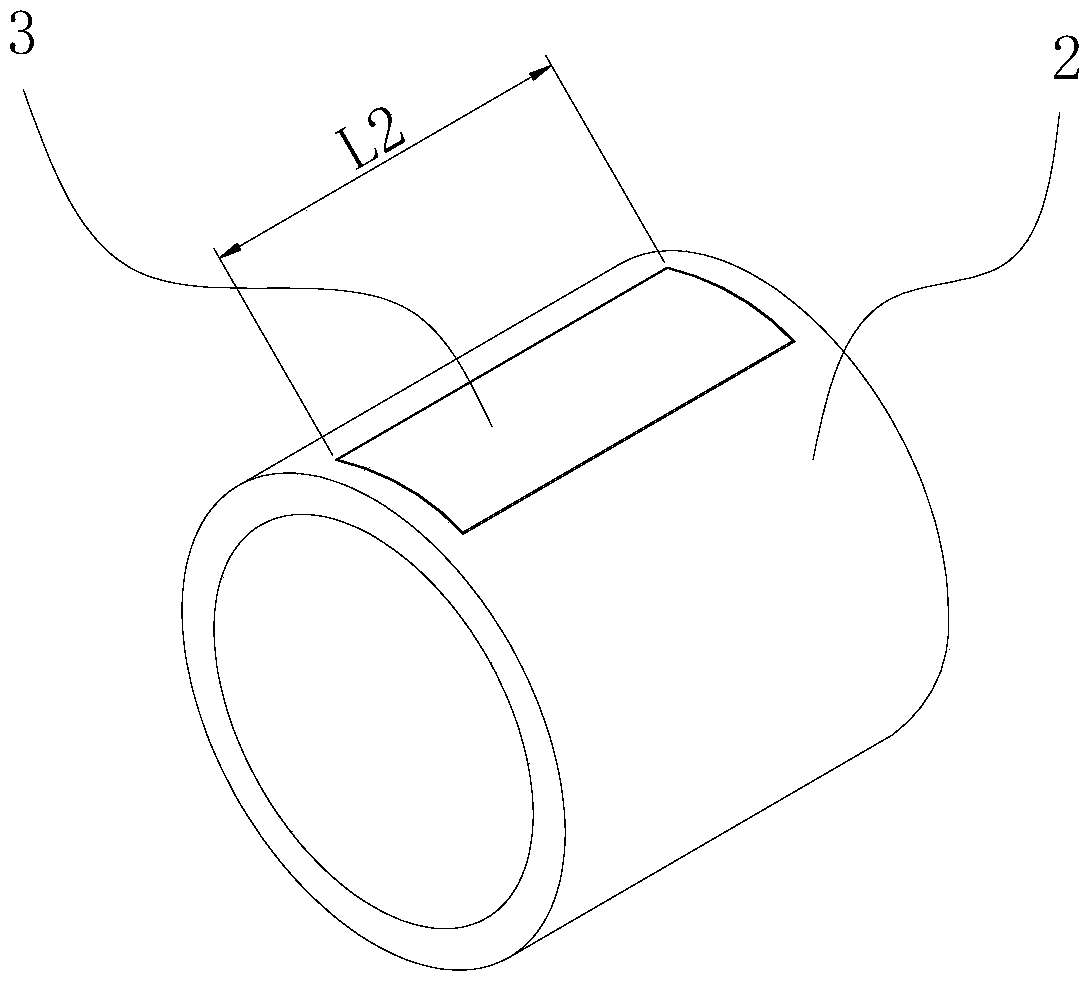

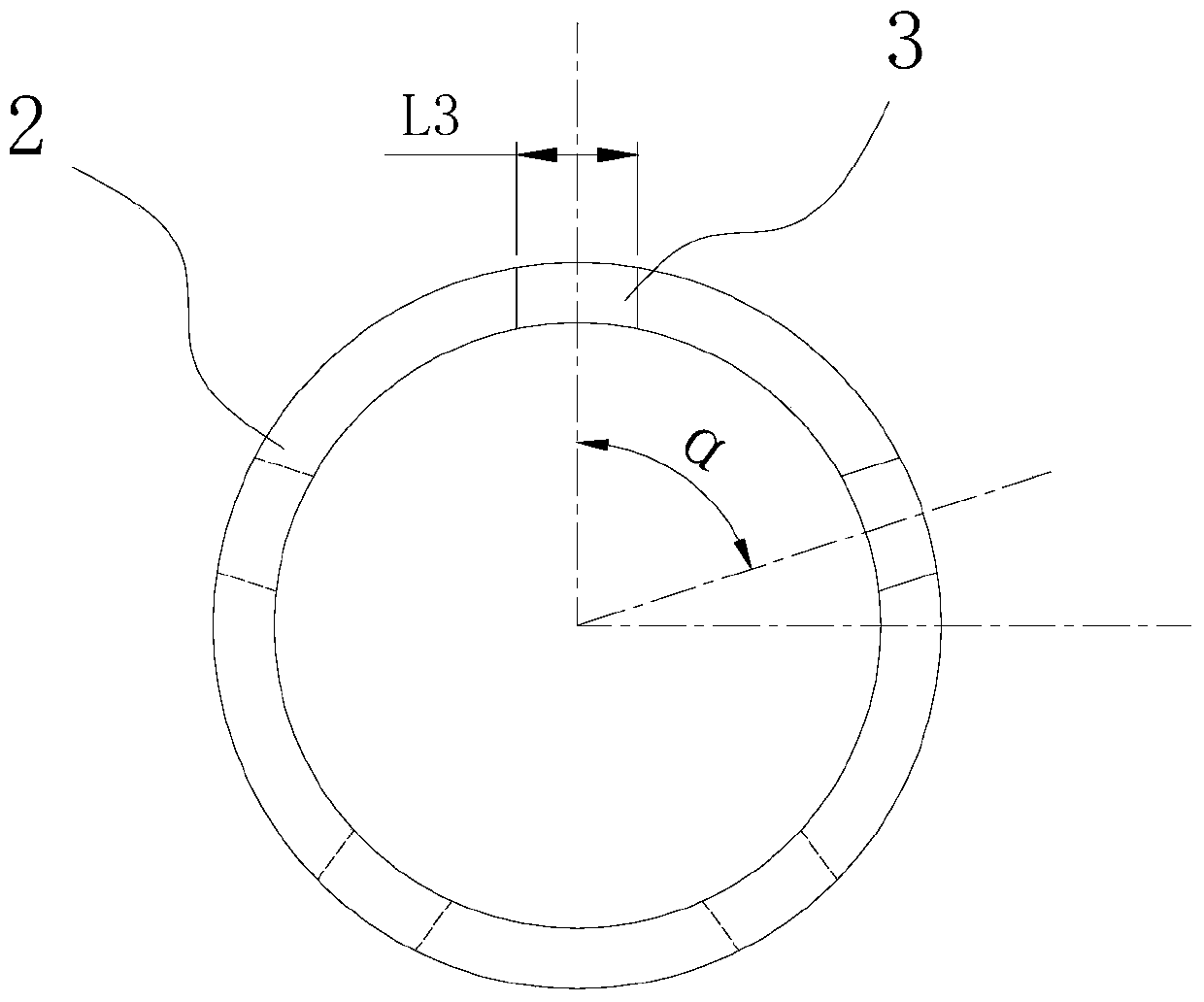

[0053] a. Cut a section of horizontal pipe section from the cold-drawn seamless steel pipe, the longitudinal length of which is not less than 40 mm, and take a metallographic sample with inner and outer surfaces every 90 degrees in the horizontal direction of the pipe section, and take a total of 4 samples , the longitudinal length of which is not less than 30mm, and the sample includes the sample cut from the thinnest wall thickness of cold-drawn seamless steel pipe;

[0054] b. The longitudinal surface of the sample is used as the inspection surface;

[0055] c. Preliminarily grind the sample on the grinder, rinse the ground sample with clean water, and then put the grinding surface on the metallographic sandpaper of 280#-600#--800#--1000# in turn Fine grinding; each time w...

Embodiment 2

[0059] Embodiment 2 specification is Detection of Microporous Defects in Seamless Steel Tubes of 30CrMo Gas Cylinders and Their Grading

[0060] Specific steps are as follows:

[0061] a. Cut a section of horizontal pipe section from the cold-drawn steel pipe, the longitudinal length of which is not less than 40 mm, and take a metallographic sample with inner and outer surfaces every 90 degrees in the horizontal direction of the pipe section, and take 4 samples in total, of which The longitudinal length is not less than 30 mm, and the sample includes the sample cut from the thinnest area of cold-drawn seamless steel pipe;

[0062] b. The inspection surface is the longitudinal inspection surface of the sample;

[0063] c. Preliminarily grind the sample on the grinder, rinse the ground sample with clean water, and then put the grinding surface on the metallographic sandpaper of 280#-600#--800#--1000# in turn Fine grinding; each time when the next finer sandpaper is changed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com