Embedded machine vision printing quality intelligent detecting system

A technology of machine vision and printing quality, applied in the direction of optical testing for flaws/defects, etc., can solve problems affecting the quality and cost of printed products, waste of printing materials, lack of core technology, etc., to achieve cost saving and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

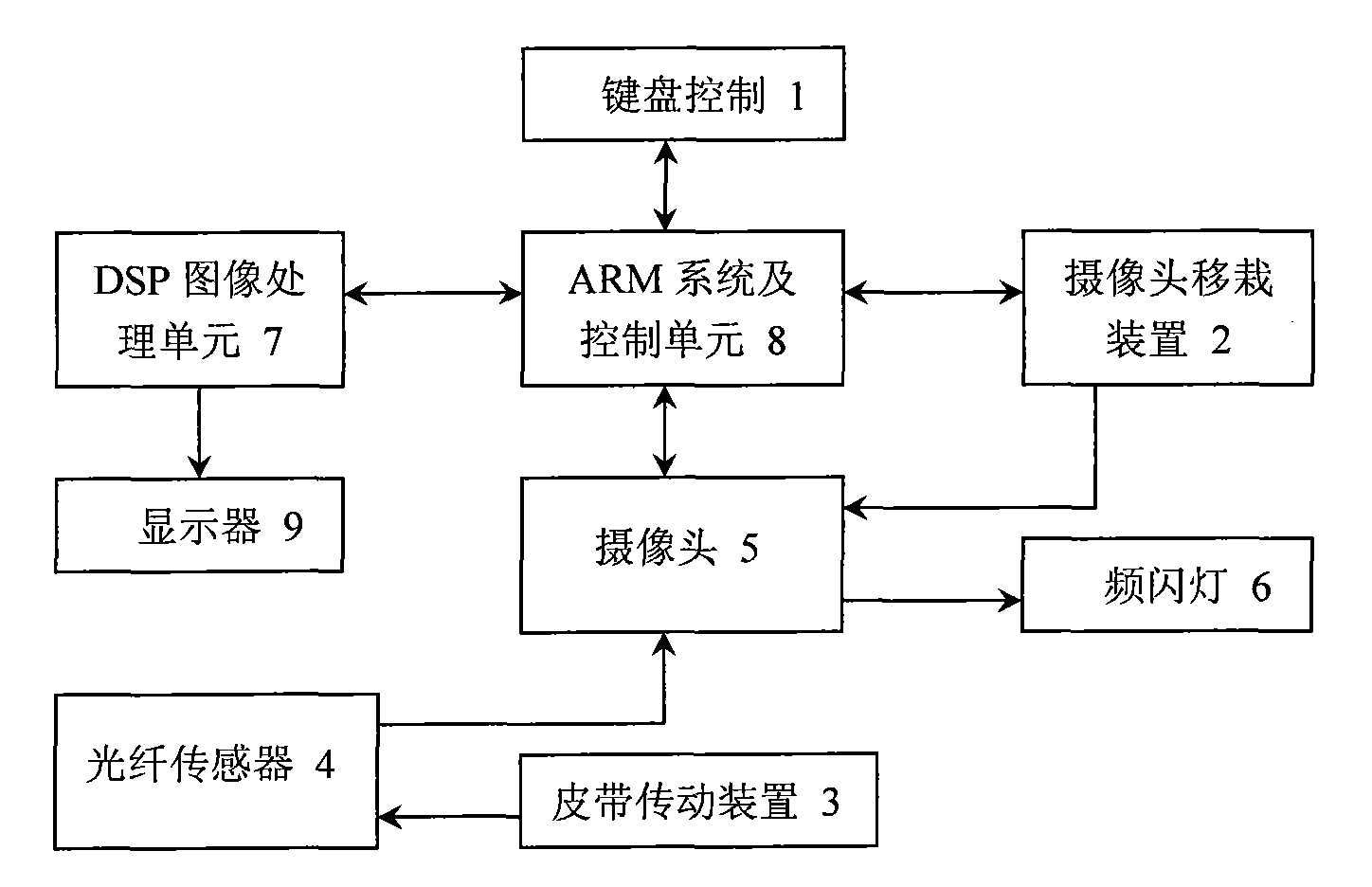

[0018] Such as figure 1 As shown, the present embodiment includes prior art: keyboard control 1, optical fiber sensor 4, camera 5, strobe light 6, DSP image processing unit 7, ARM system and control unit 8 and display 9, wherein:

[0019] Keyboard control 1 has two modes of automatic tour and manual trigger.

[0020] Optical fiber sensor 4, camera 5 and strobe light 6 are used to capture images. This example uses MVC1000 CMOS camera. Since the signal output by the camera is a digital signal, the captured image can be directly transmitted to the ARM system and control unit 8.

[0021] In the ARM system and control unit 8, this example uses the S3C2410 chip developed by Samsung as the main controller (hereinafter referred to as ARM9). Task support capability and expansion capability, as well as a series of features such as small size, low power consumption, and high performance. S3C2410 and peripheral chip FlASH, SDRAM memory form the core of the whole system, responsible for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com